Abstract

Passive components have continuously improved in recent years in miniaturization, multi-functionality, performance, and energy efficiency. The requirements of portable devices, home appliances, automobiles, industrial equipment, and other products demand these improvements. The passive components used in these products have had to continuously become smaller and thinner to meet ever-higher performance requirements. During the last several years, the demand for power inductors with high-rated current has increased rapidly due to the diversification and reduction in operating voltage in portable electronic devices. The low-temperature firing NiCuZn ferrites and Fe-based alloy powders for inductors have attracted much attention in recent years, while the review of the materials and processes for multilayer power inductors has not been described in the open literature to our best knowledge. Therefore, this article is aimed to deliver an overview on the progress of the multilayer power inductors, from materials and processes' point of view.

Copyright © 2006, Springer

Copyright © 2006, Springer

Copyright © 2006, Springer

Similar content being viewed by others

References

https://product.tdk.com/info/en/techlibrary/archives/techjournal/vol13_mlp2012-v/contents02.html.

https://www.murata.com/en-eu/products/inductor/power/learn/basic_01/basic_01_3

E.C. Snelling, Soft Ferrites: Properties and Applications, 2nd edn. (Butterworths, London, 1988)

T. Nomura and A. Nakano, Proceedings of the Sixth International Conference on Ferrites, Tokyo, 1198–1201 (1992)

T. Nakamura, Y. Okano, J. Phys. IV 7, C191–C192 (1997)

A. Nakano, T. Nomura, Ceram. Trans. 97, 285–304 (1999)

J. Töpfer, J. Mürbe, J. Electroceram. 16, 199–205 (2006)

J. Mürbe, J. Töpfer, J. Electroceram. 15, 215–221 (2005)

J. Töpfer, J. Mürbe, A. Angermann, S. Kracunovska, Int. J. Appl. Ceram. Technol. 3, 455–462 (2006)

J. Mürbe, J. Töpfer, J. Magn. Magn. Mater. 324, 578–583 (2012)

Q. Luo, H. Su, X. Tang, Z. Xu, Y. Li, Y. Jing, Ceram. Int. 44, 16005–16009 (2018)

P. Wang, Y. Li, Y. Jing, Z. Xu, X. Tang, J. Mater. Sci. 30, 21004–21010 (2019)

L. Guo, J. Li, Y. Yang, G. Wang, Y.H. Rao, G.W. Gan, H.W. Zhang, J. Mater. Sci. 30, 5437–15443 (2019)

C.X. Ouyang, S. Xiao, J. Zhu, H. Wang, Adv. Appl. Ceram. 115, 1–7 (2016)

H.I. Hsiang, J.F. Chueh, Inter. J. Appl. Ceram. Technol. 12, 1008–1015 (2015)

H. Su, X. Tang, H. Zhang, Y. Jing, Z. Zhong, J. Magn. Magn. Mater. 323, 592–595 (2011)

https://product.tdk.com/info/en/techlibrary/archives/techjournal/vol10_mlz/contents04.html

T.Y. Byun, S.C. Byeon, K.S. Hong, IEEE. Trans. Magn. 35, 3445–3447 (1999)

Z. Yue, J. Zhou, Z. Gui, L. Li, J. Magn. Magn. Mater. 264, 258–263 (2003)

O. Mirzaee, A. Shafyei, M.A. Golozar, H. Shokrollahi, J. Alloys Compd. 461, 312–315 (2008)

J. Hu, M. Yan, W. Luo, Phys. B 368, 251–260 (2005)

T.T. Ahmed, I.Z. Rahman, M.A. Rahman, J. Mater. Process. Technol. 153–154, 797–803 (2004)

H. Su, H. Zhang, X. Tang, Z. Zhong, Y. Jing, Mater. Sci. Eng. B 162, 22–25 (2009)

H.I. Hsiang, C.S. Hsi, R.L. Lin, C.Y. Chiang, Mater. Chem. Phys. 151, 295–300 (2015)

K.W. Wagner, Ann. Phys. 40, 817–855 (1913)

H.I. Hsiang, C.S. His, C.Y. Tsai, L.T. Mei, Ceram. Int. 41, 4140–4144 (2015)

M.A. Ahmed, M.A. El Hiti, J. Phys. III France 5, 775–781 (1995)

R.N. Bhowmik, R. Ranganathan, B. Ghosh, S. Kumar, S. Chattopadhyay, J. Alloys Compd. 456, 348–352 (2008)

H.I. Hsiang, Y.L. Liu, J. Alloys Compd. 472, 516–520 (2009)

H.I. Hsiang, L.T. Mei, C.S. Hsi, Y.L. Liu, F.S. Yen, J. Alloys Compd. 502, 163–168 (2010)

H.I. Hsiang, J.L. Wu, J. Magn. Magn. Mater. 374, 367–371 (2015)

H.I. Hsiang, J.L. Wu, Inter. J. Appl. Ceram. Technol. 12, 1065–1070 (2015)

A. Barba, C. Clausell, J.C. Jarque, M. Monzó, J. Eur. Ceram. Soc. 31, 2119–2128 (2011)

M. Fujimoto, J. Am. Ceram. Soc. 77, 2873–2878 (1994)

L. Schramm, G. Behr, W. Loser, K. Wetzig, J. Phase Equilib. Diff. 26, 605–612 (2005)

H. Naghib zadeh, G. Oder, J. Hesse, T. Reimann, J. Töpfer, T. Rabe, J. Electroceram. 37, 100–109 (2016)

H.I. Hsiang, W.C. Kuo, C.S. Hsi, J. Eur. Ceram. Soc. 37, 2123–2128 (2017)

L. Huan, X. Tang, H. Su, H. Zhang, Y. Jing, J. Mater. Sci. 26, 3275–3281 (2015)

S. Yan, L. Dong, Z. Chen, X.N. Wang, Z. Feng, J. Magn. Magn. Mater. 353, 47–50 (2014)

L. Huan, X. Tang, H. Su, H. Zhang, Y. Jing, B. Liu, IEEE Trans. Magn. 50, 2006104 (2014)

P. Wang, X. Tang, H. Zhang, S. Che, Y. Li, Y. Jing, J. Alloys Compd. 803, 812–817 (2019)

H. Su, C. Zhao, Y. Li, Y. Jing, H. Zhang, X. Tang, Mater. Res. Bull. 107, 37–40 (2018)

https://www.sunlordinc.com/UploadFiles/2014/03/19151140902FCA6B.pdf

A. Albrecht, J. Botiov, M. Fischer, K.H. Drüe, M. Hintz, and H. Wurmus, 14th European Microelectronics and Packaging Conference & Exhibition (2003) pp. 23–25.

H.D. Rowland, W.P. King, J. Micromech. Microeng. 4, 1625–1563 (2004)

J.M. Li, C. Liu, H. Qiao, L. Zhu, G. Chen, X.D. Dai, J. Micromech. Microeng. 18, 015008 (2008)

P.P. Shiu, G.K. Knopf, M. Ostojic, S. Nikumb, J. Micromech. Microeng. 18, 025012 (2008)

D. Andrijasevic, W. Smetana, J. Zehetner, S. Zoppel, W. Brenner, Microelectron. Eng. 84, 1198–1201 (2007)

T. Rabe, P. Kuchenbecker, B. Schulz, M. Schmidt, Int. J. Appl. Ceram. Technol. 4, 38–46 (2007)

X.C. Shan, H.P. Maw, R.T. Tjeung, S.H. Ling, C.W. Lu, R. Jachowicz, Microsyst. Technol. 14, 1405–1409 (2008)

H.I. Hsiang, C.C. Chen, W.C. Kuo, Ceram. Inter. 43, 13853–13859 (2017)

Multi-layered ferrite substrate for DC–DC converters. Hitach Metal Techol. Rev. 25, 65 (2009)

R.T. Hsu, J.H. Jean, Y.Y. Hung, J. Am. Ceram. Soc. 91, 2051–2054 (2008)

T.J. Garino, H.K. Bowen, J. Am. Ceram. Soc. 73, 251 (1990)

J.C. Chang, J.H. Jean, J. Am. Ceram. Soc. 92, 1946–1950 (2009)

H. Thust, M.Hintz, A. Albrecht, in SMTA Pan Pacific Conference, 2004, Hawaii, USA

H.I. Hsiang, J.F. Chueh, Inter. J. Appl. Ceram. Technol. 12(S2), E194–E201 (2015)

L.P. Lefebvre, S. Pelletier, C. Gélinas, J. Magn. Magn. Mater. 176, L93–L96 (1997)

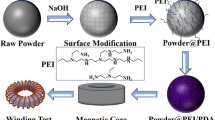

L.F. Fan, H.I. Hsiang, J.J. Hung, Appl. Surf. Sci. 433, 133–138 (2018)

A.H. Taghvaei, H. Shokrollahi, K. Janghorban, J. Alloys Compd. 481, 681–686 (2009)

H.Y. Jiang, W. Zhong, X.L. Wu, N.J. Tang, W. Liu, Y.W. Du, J. Alloys Compd. 384, 264–267 (2004)

H.I. Hsiang, L.F. Fan, J.J. Hung, J. Magn. Magn. Mater. 447, 1–8 (2018)

I. Hemmati, H.R. Madaah Hosseini, A. Kianvash, J. Magn. Magn. Mater. 305, 147–151 (2006)

S. Nakaharaa, E.A. Périgoa, Y. Pittini-Yamada, Y. de Hazan, T. Graule, Acta Mater. 58, 5695–5703 (2010)

H.I. Hsiang, L.F. Fan, K.T. Ho, J. Magn. Magn. Mater. 444, 1–6 (2017)

H.I. Hsiang, L.F. Fan, K.T. Ho, IEEE Trans. Magn. 54, 2000407 (2018)

Y.P. Wu, H.Y. Chiang, H.I. Hsiang, J. Mater. Sci. 30, 8080–8088 (2019)

Y.P. Wu, H.Y. Chiang, H.I. Hsiang, AIP Adv. 8, 085006 (2018)

Y.P. Wu, The AgCrO2 formation mechanism and prevention methods during co-firing silver inner electrode and Fe-Si-Cr alloy powders in metal multilayer chip power inductor. Ph.D. dissertation, National Cheng Kung University (2019)

Acknowledgements

This work was financially co-sponsored by the Ministry of Science and Technology of Taiwan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hsiang, HI. Progress in materials and processes of multilayer power inductors. J Mater Sci: Mater Electron 31, 16089–16110 (2020). https://doi.org/10.1007/s10854-020-04188-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04188-8