Abstract

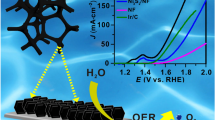

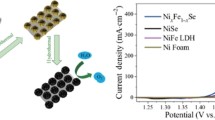

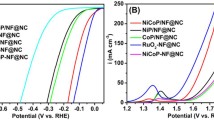

Transition metal selenides with special structures and rational component modulation have received tremendous research interest to ameliorate the sluggish kinetics of oxygen evolution reaction (OER) in electrochemical water splitting. Here, we propose a facile hydrothermal treatment strategy to prepare porous Fe-incorporated NiSe microspheres via in situ selenization of iron–nickel foam. The as-obtained 3D integrated anode demonstrates excellent electrocatalytic performance towards OER in concentrated alkaline media (1.0 M KOH), with a small onset overpotential of 170 mV, an overpotential as low as 236 mV to achieve a current density of 50 mA cm−2, and a small Tafel slope of 53 mV dec−1. The overpotential at 50 mA cm−2 shows no obvious change during the whole durability test for 24 h, indicating long-term stable electrocatalytic activity. Characterizations of the electrode after stability test reveal the oxidation of the crystallized Fe-incorporated NiSe microspheres which probably generates amorphous Ni(Fe)OOH. The microspheres were partially dissolved and connected with each other to form a wormlike porous structure. The superior OER activity is largely attributed to the highly active Fe–Ni selenide and derived oxyhydroxide of 3D porous structure on the FeNi foam substrate. The facile synthesis strategy in this work can be conveniently applied to the preparation of a variety of selenides of metal foams with different compositions as highly efficient electrocatalysts.

Similar content being viewed by others

References

A. Landman, H. Dotan, G.E. Shter, M. Wullenkord, A. Houaijia, A. Maljusch, G.S. Grader, A. Rothschild, Nat. Mater. 16, 646 (2017)

J.A. Turner, Science 305, 972 (2004)

J. Yeston, Science 355, 143 (2017)

G.W. Crabtree, M.S. Dresselhaus, M.V. Buchanan, Phys. Today 57, 39 (2004)

C.C.L. McCrory, S. Jung, J.C. Peters, T.F. Jaramillo, J. Am. Chem. Soc. 135, 16977 (2013)

H. Dau, C. Limberg, T. Reier, M. Risch, S. Roggan, P. Strasser, ChemCatChem 2, 724 (2010)

N.-T. Suen, S.-F. Hung, Q. Quan, N. Zhang, Y.-J. Xu, H.M. Chen, Chem. Soc. Rev. 46, 337 (2017)

E. Willinger, C. Massué, R. Schlögl, M.G. Willinger, J. Am. Chem. Soc. 139, 12093 (2017)

H. Over, Chem. Rev. 112, 3356 (2012)

X. Zou, Y. Zhang, Chem. Soc. Rev. 44, 5148 (2015)

J. Li, Y. Wang, T. Zhou, H. Zhang, X. Sun, J. Tang, L. Zhang, A.M. Al-Enizi, Z. Yang, G. Zheng, J. Am. Chem. Soc. 137, 14305 (2015)

Y. Li, P. Hasin, Y. Wu, Adv. Mater. 22, 1926 (2010)

L. Zhang, Q. Liang, P. Yang, Y. Huang, W. Chen, X. Deng, H. Yang, J. Yan, Y. Liu, Int. J. Hydrogen Energ. 44, 24209 (2019)

K. Wang, C. Liu, W. Wang, N. Mitsuzaki, Z. Chen, J. Mater. Sci. Mater. Electron. 30, 4144 (2019)

C. Liu, K. Wang, J. Zhang, X. Zheng, Q. Liang, Z. Chen, J. Mater. Sci. Mater. Electron. 29, 10744 (2018)

Y. Li, Z. Zhou, H. Xu, X. Liao, G. Cheng, M. Sun, L. Yu, J. Mater. Sci. Mater. Electron. 30, 18424 (2019)

C. Hao, H. Linfeng, C. Min, Y. Yan, W. Limin, Adv. Funct. Mater. 24, 934 (2014)

S. Chen, J. Duan, M. Jaroniec, S.Z. Qiao, Angew. Chem. Int. Edit. 52, 13567 (2013)

S. Arumugam, G. Pandian, S. Sangaraju, Adv. Funct. Mater. 26, 4661 (2016)

J. Tie, S. Peng, G. Diao, F. Chen, M. Sun, L. Yu, J. Zhou, Y. Li, J. Mater. Sci. Mater. Electron. 29, 2251 (2018)

X. Xu, F. Song, X. Hu, Nat. Commun. 7, 12324 (2016)

X. Shi, H. Wang, P. Kannan, J. Ding, S. Ji, F. Liu, H. Gai, R. Wang, J. Mater. Chem. A 7, 3344 (2019)

X. Wang, B. Zheng, B. Yu, B. Wang, W. Hou, W. Zhang, Y. Chen, J. Mater. Chem. A 6, 7842 (2018)

C. Liu, K. Wang, X. Zheng, X. Liu, Q. Liang, Z. Chen, Carbon 139, 1 (2018)

M. Zhuang, Y. Ding, X. Ou, Z. Luo, Nanoscale 9, 4652 (2017)

G. Chen, T. Ma, Z. Liu, N. Li, Y. Su, K. Davey, S. Qiao, Adv. Funct. Mater. 26, 3314 (2016)

L. Marc, K.C. Sandra, P. Christian, S. Hans-Peter, A. Markus, S. Menny, Angew. Chem. Int. Edit. 54, 12361 (2015)

C.Y. Son, I.H. Kwak, Y.R. Lim, J. Park, Chem. Commun. 52, 2819 (2016)

K. Fominykh, P. Chernev, I. Zaharieva, J. Sicklinger, G. Stefanic, M. Döblinger, A. Müller, A. Pokharel, S. Böcklein, C. Scheu, T. Bein, D. Fattakhova-Rohlfing, ACS Nano 9, 5180 (2015)

J. Xie, H. Qu, F. Lei, X. Peng, W. Liu, L. Gao, P. Hao, G. Cui, B. Tang, J. Mater. Chem. A 6, 16121 (2018)

J. Wang, X. Teng, Y. Niu, L. Guo, J. Kong, X. He, Z. Chen, RSC Adv. 9, 21679 (2019)

P. Ganesan, A. Sivanantham, S. Shanmugam, J. Mater. Chem. A 4, 16394 (2016)

S. Qin, J. Lei, Y. Xiong, X. Xu, X. Geng, J. Wang, RSC Adv. 9, 10231 (2019)

Z. Ma, R. Li, M. Wang, H. Meng, F. Zhang, X.-Q. Bao, B. Tang, X. Wang, Electrochim. Acta 219, 194 (2016)

F. Hu, H. Wang, Y. Zhang, X. Shen, G. Zhang, Y. Pan, J.T. Miller, K. Wang, S. Zhu, X. Yang, C. Wang, X. Wu, Y. Xiong, Z. Peng, Small 15, 1901020 (2019)

Z. Wang, J. Li, X. Tian, X. Wang, Y. Yu, K.A. Owusu, L. He, L. Mai, A.C.S. Appl, Mater. Inter. 8, 19386 (2016)

J.-Q. Chi, X. Shang, F. Liang, B. Dong, X. Li, Y.-R. Liu, K.-L. Yan, W.-K. Gao, Y.-M. Chai, C.-G. Liu, Appl. Surf. Sci. 401, 17 (2017)

J. Yu, G. Cheng, W. Luo, Nano Res. 11, 2149 (2018)

J. Du, A. Yu, Z. Zou, C. Xu, Inorg. Chem. Front. 5, 814 (2018)

W. Tang, S. Zuo, J. Wang, Y. Mi, Z. Chen, Electrochim. Acta 247, 835 (2017)

Y.-Y. Sun, M.-Y. Jiang, L.-K. Wu, G.-Y. Hou, Y.-P. Tang, M. Liu, Sustain. Energy Fuels 4, 582 (2020)

C. Cao, D.-D. Ma, Q. Xu, X.-T. Wu, Q.-L. Zhu, Adv. Funct. Mater. 29, 1807418 (2019)

Y. Liang, Q. Liu, A.M. Asiri, X. Sun, Y. He, Int. J. Hydrogen Energ. 40, 13258 (2015)

X. Bu, R. Wei, W. Gao, C. Lan, J.C. Ho, J. Mater. Chem. A 7, 12325 (2019)

C. Tang, A.M. Asiri, X. Sun, Chem. Commun. 52, 4529 (2016)

A. Li, C. Wang, H. Zhang, Z. Zhao, J. Wang, M. Cheng, H. Zhao, J. Wang, M. Wu, J. Wang, Electrochim. Acta 276, 153 (2018)

Q. Zhang, T. Li, J. Liang, N. Wang, X. Kong, J. Wang, H. Qian, Y. Zhou, F. Liu, C. Wei, Y. Zhao, X. Zhang, J. Mater. Chem. A 6, 7509 (2018)

Y. Wu, R. Su, Y. Li, Z. Wang, Z. Lü, L. Xu, B. Wei, Electrochim. Acta 309, 415 (2019)

Acknowledgements

This work was financially supported by the Innovation Platform Foundation Project of Hunan Education Department of China (No. 18K087), the Natural Science Foundation for Youths of Hunan Province of China (No. 2019JJ50206), and the Scientific Research Project of Hunan Education Department of China (No.19B230).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, L., Yang, P., Chen, W. et al. Direct growth of Fe-incorporated NiSe microspheres on FeNi alloy foam as a highly efficient electrocatalyst for oxygen evolution reaction. J Mater Sci: Mater Electron 31, 15968–15975 (2020). https://doi.org/10.1007/s10854-020-04158-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04158-0