Abstract

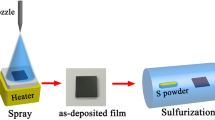

In this work, a comprehensive study on the influences of the various synthesizing parameters of monoclinic Cu2SnS3 using the RF sputtering method, followed by the sulfurization process, is investigated. In particular, the impact of sputtering power and pressure on multi-material target Cu–Sn (compositional ratio Cu:Sn of 52:48%) was examined. All samples exhibited a monoclinic structure with similar split bandgaps around 0.9 eV. Increasing sputtering power showed direct effects on the sputtered Cu/Sn atoms ratio and the secondary phases obtained. The increase of sputtering pressure causes gas droplets and blistering on the film surfaces. The effects of changing the sulfurization temperature and the sulfur powder amount were also studied. The increase in the sulfurization temperature reduces the surface roughness, increases film crystallinity, and minimizes Cu-based secondary phases. The sulfur amount used during the sulfurization process showed a vital impact on film formation. Using a small amount of sulfur produced a partially sulfurized film that exhibited a poor performance solar cell. A power conversion efficiency of 1.94% is achieved with the optimized condition for the bare Cu2SnS3 without doping or heat treatment for the fabricated cell.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author, Mohamed S. Abdel-Latif, upon reasonable request.

References

Y. Hamakawa, Thin-Film Solid Cells (Springer, New York, 2004), pp. 1–14

D.J. Feldman, R.M. Margolis, Q4 2018/Q1 2019 Solar Industry Update (National Renewable Energy Lab.(NREL), Golden, CO (United States) (2019)

M.A. Green, E.D. Dunlop, D.H. Levi, J. Hohl-Ebinger, M. Yoshita, A.W.Y. Ho‐Baillie, Prog. Photovoltaics Res. Appl. 27, 565 (2019)

T. Bayazıt, M.A. Olgar, T. Küçükömeroğlu, E. Bacaksız, M. Tomakin, J. Mater. Sci. Mater. Electron. 30, 12612 (2019)

S. Abdelhaleem, A.E. Hassanien, R. Ahmad, M. Schuster, A.H. Ashour, M. Distaso, W. Peukert, P.J. Wellmann, J. Electron. Mater. 47, 7085 (2018)

A.C. Lokhande, K.V. Gurav, E. Jo, M. He, C.D. Lokhande, J.H. Kim, Opt. Mater. (Amst). 54, 207 (2016)

G. Sunny, T. Thomas, D.R. Deepu, C.S. Kartha, K.P. Vijayakumar, Optik (Stuttg) 144, 263 (2017)

Q. Chen, Z. Jia, H. Yuan, W. Zhu, Y. Ni, X. Zhu, X. Dou, J. Mater. Sci. Mater. Electron. 30, 4519 (2019)

A. Nagoya, R. Asahi, R. Wahl, G. Kresse, Phys. Rev. B 81, 113202 (2010)

M.S.A. Latif, N.M. Shaalan, A. A. El-Moneim, Key Engineering Materials. Trans Tech Publ, pp. 62–66 (2018)

J. Wu, C. Gao, L. Han, S. Shen, M. Jia, L. Wang, L. Jiang, F. Liu, J. Mater. Sci. Mater. Electron. 30, 4378 (2019)

R. Chierchia, F. Pigna, M. Valentini, C. Malerba, E. Salza, P. Mangiapane, T. Polichetti, A. Mittiga, Phys. Status Solidi 13, 35 (2016)

K. Tanaka, T. Maeda, H. Araki, Sol. Energy 199, 143 (2020)

Y. Kim, I.-H. Choi, S.Y. Park, Thin Solid Films 666, 61 (2018)

S.A. Zaki, M.I. Abd-Elrahman, A.A. Abu-Sehly, N.M. Shaalan, M.M. Hafiz, Mater. Sci. Semicond. Pro. 115, 105123 (2020)

N. Thota, M. Kumar, M. Vishwakarma, B.R. Mehta, Thin Solid Films 677, 62 (2019)

E.S. Hossain, P. Chelvanathan, S.A. Shahahmadi, B. Bais, M. Akhtaruzzaman, S.K. Tiong, K. Sopian, N. Amin, Sol. Energy 177, 262 (2019)

H.D. Shelke, A.C. Lokhande, J.H. Kim, C.D. Lokhande, J. Alloys Compd. 831, 154768 (2020)

K. Tanaka, M. Kowata, F. Yoshihisa, S. Imai, W. Yamazaki, Thin Solid Films 697, 137820 (2020)

M. Nakashima, J. Fujimoto, T. Yamaguchi, M. Izaki, Appl. Phys. Express 8, 42303 (2015)

D. Avellaneda, M.T.S. Nair, P.K. Nair, J. Electrochem. Soc. 157, D346 (2010)

E.S. Hossain, P. Chelvanathan, S.A. Shahahmadi, M.T. Ferdaous, B. Bais, S.K. Tiong, N. Amin, Chalcogenide Lett. 15, 499 (2018)

Y. Zhao, X. Han, B. Xu, C. Dong, J. Li, X. Yan, J. Mater. Sci. Mater. Electron. 30, 17947 (2019)

P.R. Guddeti, S. Gedi, K.T.R. Reddy, Mater. Sci. Semicond. Process. 86, 164 (2018)

Q. Zhang, H. Deng, J. Yu, B. Xu, J. Tao, P. Yang, L. Sun, J. Chu, Mater. Lett. 228, 447 (2018)

M.R. Pallavolu, C.-D. Kim, V.R.M. Reddy, S. Gedi, C. Park, Sol. Energy 188, 209 (2019)

H. Metin, R. Esen, J. Cryst. Growth 258, 141 (2003)

F.I. Ezema, Y. Kayama, I.C. Amaechi, T. Hiramatsu, A.C. Nwanya, R.U. Osuji, M. Malik, M. Sugiyama, Chalcogenide Lett. 11, (2014)

K.-Y. Chan, B.-S. Teo, J. Mater. Sci. 40, 5971 (2005)

K. Suzuki, J. Chantana, T. Minemoto, Appl. Surf. Sci. 414, 140 (2017)

W. Wang, H. Shen, H. Yao, J. Li, J. Jiao, J. Mater. Sci. Mater. Electron. 26, 1449 (2015)

Y. Dong, J. He, X. Li, Y. Chen, L. Sun, P. Yang, J. Chu, J. Alloys Compd. 665, 69 (2016)

U. Chalapathi, B. Poornaprakash, S.-H. Park, Vacuum 131, 22 (2016)

J. De Wild, E. Kalesaki, L. Wirtz, P.J. Dale, Phys. Status Solidi (RRL)–Rapid Res. Lett. 11, 1600410 (2017)

I.G. Orletskii, M.N. Solovan, F. Pinna, G. Cicero, P.D. Mar’yanchuk, E.V. Maistruk, E. Tresso, Phys. Solid State 59, 801 (2017)

I.M. El Radaf, H.Y.S. Al-Zahrani, A.S. Hassanien, J. Mater. Sci. Electron. 31, 3228 (2020)

A.S. Hassanien, A.A. Akl, Superlattices Microstruct. 89, 153 (2016)

A.S. Hassanien, A.A. Akl, J. Alloys Compd. 648, 280 (2015)

A.S. Hassanien, I.M. El, Radaf, Phys. B Condens. Matter 585, 412110 (2020)

D.S. Arteev, A.V. Sakharov, E.E. Zavarin, W.V. Lundin, A.N. Smirnov, V.Y. Davydov, M.A. Yagovkina, S.O. Usov, A.F. Tsatsulnikov, J. Phys. Conf. Ser. 1135, 012050 (2018)

A.S. Hassanien, A.A. Akl, Phys. B Condens. Matter 576, 411718 (2020)

P.M. Kaminski, S. Yilmaz, A. Abbas, F. Bittau, J.W. Bowers, R.C. Greenhalgh, J.M. Walls, In: proceedings of the 2017 IEEE 44th Photovolt. Spec. Conf. (IEEE, 2017), pp. 3430–3434 (2017)

P. Bras, J. Sterner, C. Platzer-Björkman, J. Vac. Sci. Technol. A Vac. Surf. Film 33, 61201 (2015)

M.I. Ojovan, K.P. Travis, R.J. Hand, J. Phys. Condens. Matter 19, 415107 (2007)

S. Shirakata, K. Ohkubo, Y. Ishii, T. Nakada, Sol. Energy Mater. Sol. Cells 93, 988 (2009)

J. Chantana, K. Tai, H. Hayashi, T. Nishimura, Y. Kawano, T. Minemoto, Sol. Energy Mater. Sol. Cells 206, 110261 (2020)

G.Y. Ashebir, C. Dong, J. Chen, W. Chen, R. Liu, Q. Zhao, Z. Wan, M. Wang, J. Phys. D. Appl. Phys. 53, 115101 (2020)

S. Sato, H. Sumi, G. Shi, M. Sugiyama, Phys. Status Solidi 12, 757 (2015)

M. He, A.C. Lokhande, I.Y. Kim, U.V. Ghorpade, M.P. Suryawanshi, J.H. Kim, J. Alloys Compd. 701, 901 (2017)

J.Y. Lee, I.Y. Kim, M.P. Surywanshi, U.V. Ghorpade, D.S. Lee, J.H. Kim, Sol. Energy 145, 27 (2017)

Acknowledgements

The authors would like to express their sincere gratitude to the Ministry of Higher Education (MOHE) – Egypt for their financial support and Tokyo University of Science - Noda Campus for offering the facilities and tools contribution.

Funding

This work was funded by the Ministry of Higher Education (MOHE) – Egypt and supported by the Tokyo University of Science - Noda Campus by offering the facilities and tools.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdel-Latif, M.S., Magdy, W., Tosuke, T. et al. A comprehensive study on Cu2SnS3 prepared by sulfurization of Cu–Sn sputtered precursor for thin-film solar cell applications. J Mater Sci: Mater Electron 31, 14577–14590 (2020). https://doi.org/10.1007/s10854-020-04018-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04018-x