Abstract

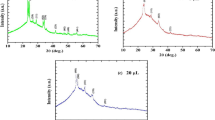

The effect of six different substrate-inclined angle with the vessel on the characteristics properties of the Zinc Oxide (ZnO) nanorods was explored and reported. The vertically well-aligned ZnO Nanorods (NRs) were synthesized on glass substrates by using the low-cost chemical bath deposition (CBD) method at 90 °C. The RF magnetron sputtering has been employed to deposit the ZnO nanoseed layer on glass substrates and electrodes for UV photodetectors (PDs) devices. The morphological, structural, and optical properties of the synthesized ZnO NRs have been investigated using various characterization techniques for different substrate- inclined angles. Also, the high-quality UV photodetector-based ZnO NRs have been fabricated for the optimum substrate-inclined angle of 70° with the vessel by applying a different bias voltage. The results found that variation of substrate-inclined angles have the remarkable and significant effect on the shape, size, length, alignment, density distribution, structure, lattice parameters, crystalline size, energy band gap (Eg), and optical properties of ZnO NRs. The average diameters and length of grown ZnO NRs were in the range of (58–249) nm and (303–2518) nm, respectively. The high aspect ratio, length, and growth rate were observed for ZnO nanorods grown at 70° substrate-inclined angle. The preferred orientation of ZnO NRs was along (002) hexagonal wurtzite plane and the intensity of (002) diffraction peak for ZnO NRs was increased with increasing substrate-inclined angles. The average crystalline size was in range of (46.7–58.8) nm. The average transmittance of ZnO NRs showed a reduction in the range of (44.5–3.3)% as the substrate angle increased. The optical studies show that the synthesized ZnO NRs have the direct Eg in the range of (3.16–3.254) eV. The fabricated UV PD-based ZnO NRs showed high performance and quality. The different bias voltage study shows that the ZnO nanorod UV PD has higher stability and repeatability at 5 V bias voltage. The PDs device exhibited the responsivity value of 3.49903 A/W to 390 nm light wavelength at 5 V, which is higher than those reported for UV PDs-based ZnO NRs. At 5 V bias voltages, the fabricated UV PDs showed a faster response and recovery times of 0.3402 S and 0.1639 S, respectively.

source wavelength at fixed 5 V bias voltage & under 0.57 mW/cm2 UV light illumination of ZnO nanorods

Similar content being viewed by others

References

S. Liu, B. Li, H. Kan, M.Y. Li, B. Xie, S. Jiang, X. Zhu, J. Mater. Sci. 28, 15891–15898 (2017)

A.M. Bazargan, F. Sharif, S. Mazinani, N. Naderi, J. Mater. Sci. 27, 8221 (2016)

D.I. Son, B.W. Kwon, D.H. Park, W.S. Seo, Y. Yi, B. Angadi, C.L. Lee, W.K. Choi, Nat. Nanotechnol. 7, 465 (2012)

Y. Luo, B. Yin, H. Zhang, Y. Qiu, J. Lei, Y. Chang, Y. Zhao, J. Ji, L. Hu, J. Mater. Sci. 27, 2342–2348 (2016)

B.K. Sonawane, V. Shelke, M.P. Bhole, D.S. Patil, J. Phys. Chem. Solids 72, 1442–1446 (2011)

A.F. Abdulrahman, S.M. Ahmed, N.M. Ahmed, M.A. Almessiere, Dig. J. Nan. Biostruct. 11(4), 1073–1082 (2016)

V.R. Shinde, C.D. Lokhande, R.S. Mane, S.-H. Han, Appl. Surf. Sci. 245, 407–413 (2005)

O. Lupan, L. Chow, G. Chai, B. Roldan, A. Naitabdi, A. Schulte, H. Heinrich, Mater. Sci. Eng. B 145, 57–66 (2007)

F. Cao, X. Ji, J. Mater. Sci. Issue 3/2020.

O. Yalcin, “Nanorods”, InTech Janeza Trdine 9, 51000 Rijeka, Croatia (2012).

T.A. Hatton, (American Chemical Society, Washington, DC, 2008).

E. Roduner, Size matters: why nanomaterials are different. Chem. Soc. Rev. 35, 583 (2006)

A.F. Abdulrahman, S.M. Ahmed, M.A. Almessiere, Dig. J. Nan. Biostruct. 12(4), 1001–1009 (2017)

D. Montenegro et al., J. Appl. Phys. 113, 143513–143519 (2013)

J.H. Choi, H. Tabata, T. Kawai, J. Cryst. Growth 226(4), 493–500 (2001)

P. Yang et al., Adv. Funct. Mater. 12, 323 (2002)

J.Y. Lee et al., Thin Solid Films 403, 553 (2002)

R. Shabannia, H. Abu-Hassan, Mater. Lett. 90, 156–158 (2013)

Y. Ryu, T.S. Lee, J.A. Lubguban, H.W. White, B.J. Kim, Y.S. Park, C.J. Youn, Appl. Phys. Lett. 88, 241108 (2006)

A. Fattah, S.M. Ahmed, N.M. Ahmed, Sci. J. Univ. Zakho 6(4), 160–165 (2018)

R.C. Wang, H.Y. Lin, S.J. Chen, Y.F. Lai, M.R.S. Huang, Appl. Phys. A Mater. Sci. Process. 96, 775–781 (2009)

Q. Tao, S. Li, Q.Y. Zhang, D.W. Kang, J.S. Yang, W.W. Qiu, K. Liu, Mater. Res. Bull. 54, 6–12 (2014)

A.F. Abdulrahman, S.M. Ahmed, N.M. Ahmed, Sci. J. Univ Zakho 5(1), 128–135 (2017)

S. George, G. Katerina, S.N. Yannopoulos, Cryst. Growth Des. 16(4), 2140–2150 (2016)

P.K. Nair, M.T.S. Nair, A. Fernandez, M. Ocampo, Prospects of chemically deposited metal chalcogenide thin films for solar control applications. J. Phys. D 22, 829 (1989)

L.L. Yang, Q.X. Zhao, M. Willander, J. Alloys Compd. 469, 623–629 (2009)

A. Echresh, M.Z. Shoushtari, M. Farbod, Mater. Lett. 110, 164–167 (2013)

P.L. Limnonthakul, D. Yangnoi, P. Bintachitt, M. Hengwattana, M. HorprathumJ, Math. Fundam. Sci. 48, 48–54 (2016)

A.F. Abdulrahman, S.M. Ahmed, N.M. Ahmed, M.A. Almessiere, Dig. J. Nan. Biostruct. 11(3), 1007–1016 (2016)

M. Law, L.E. Greene, J.C. Johnson, R. Saykally, P. Yang, Nat. Mater. 4, 455–459 (2005)

J. Elias, R. Tena-Zaera, C. Lévy-Clément, Thin Solid Films 515, 8553–8557 (2007)

F. Tong, K. Kim, Y. Wang, R. Thapa, Y. Sharma, A. Modic, A. Claude Ahyi, T. Issacs-Smith, J. Williams, H. Ahn, H. Park, D.-J. Kim, S. Lee, E. Lim, K.K. Lee, M. Park, ISRN Nanomater. 2012, 1–7 (2012)

Y.-M. Lee, H.-W. Yang, J. Solid State Chem. 184, 615–623 (2011)

N. Nagayasamy, S. Gandhimathination, V. Veerasamy, Open J. Met. 3, 8–11 (2013)

P.S. Shewale, Y.S. Yu, J. Alloys Compd. 654, 79–86 (2016)

C. Chandrinou, N. Boukos, K. Giannakopoulos, A. Lusson, A. Travlos, Superlattices Microstruct. 42, 431–437 (2007)

J. Lv, J. Zhu, K. Huang, F. Meng, X. Song, Z. Sun, Appl. Surf. Sci. 257, 7534–7538 (2011)

S. Liang, X. Bi, J. Appl. Phys. 104, 1–6 (2008)

P. Singh, A. Kumar, D. Kaur, J. Cryst. Growth. 306, 303–310 (2007)

T. Lee, H. Ryu, W.-J. Lee, J. Alloys Compd. 597, 85–90 (2014)

L. Zhang, Y. Ruan, Y. Liu, Y. Zhai, Cryst. Res. Technol. 48, 996–1002 (2013)

S. Zhang, C. Yan, H. Zhang, G. Lu, Mater. Lett. 148, 1–4 (2015)

M. Poornajar, P. Marashi, D.H. Fatmehsari, M.K. Esfahani, Ceram. Int. 42, 173–184 (2016)

A.F. Abdulrahman, S.M. Ahmed, N.M. Ahmed, M.A. Almessiere, AIP Conf. Proc. 1875, 020004 (2017)

B.K. Sonawane, M.P. Bhole, D.S. Patil, Phys. B 405, 1603–1607 (2010)

M. Gusatti, C.E.M. Campos, D.A.R. Souza, V.M. Moser, N.C. Kuhnen, H.G. Riella, J. Nanosci. Nanotechnol. 13, 8307–8314 (2013)

S.H. Mohamed, A.M. Abd El-Rahman, A.M. Salem, L. Pichon, F.M. El-Hossary, J. Phys. Chem. Solids. 67, 2351–2357 (2006)

C.C. Ting, C.H. Li, C.Y. Kuo, C.C. Hsu, H.C. Wang, M.H. Yang, Thin Solid Films 518, 4156–4162 (2010)

C.K. Kasar, U.S. Sonawane, J.P. Bange, D.S. Patil, J. Mater. Sci. 27, 8126–8130 (2016)

A. Akhiruddin, S. Sugianto, I. Irmansyah, J. Mater. Phys. Chem. 2, 34–37 (2015)

M.F. Malek, M.H. Mamat, T. Soga, S.A. Rahman, S. Abu Bakar, A.S. Ismail, R. Mohamed, S.A.H. Alrokayan, H.A. Khan, M.R. Mahmood, Jpn. J. Appl. Phys. 55, 01AE15 (2016)

J.H. Lee, I.C. Leu, M.H. Hon, J. Cryst. Growth. 275, 2069–2075 (2005)

R.N. Gayen, R. Bhar, A.K. Pal, Indian J. Pure Appl. Phys. 48, 385–393 (2010)

A.K. Qasim, L.A. Jamil, A.F. Abdulrahman, Dig. J. Nan. Biostruct. 15(1), 157–165 (2020)

L. Roza, M.Y.A. Rahman, A.A. Umar, M.M. Salleh, J. Alloys Compd. 618, 153–158 (2015)

J. Kühnle, R.B. Bergmann, J.H. Werner, J. Cryst. Growth. 173, 62–68 (1997)

C.-Y. Tsay, K.-S. Fan, S.-H. Chen, C.-H. Tsai, J. Alloys Compd. 495, 126–130 (2010)

K.L. Foo, U. Hashim, K. Muhammad, C.H. Voon, Nanoscale Res. Lett. 9, 1–10 (2014)

Y.-J. Yoon, K.-S. Park, J.-H. Heo, J.-G. Park, S. Nahm, K.J. Choi, J. Mater. Chem. 20, 2386 (2010)

L.E. Greene, M. Law, J. Goldberger, F. Kim, J.C. Johnson, Y. Zhang, R.J. Saykally, P. Yang, Angew. Chem. Int. Ed. 42, 3031–3034 (2003)

A.M. Selman et al., Appl. Surf. Sci. 305, 445 (2014)

J. Chrzanowski, Y. Kravtsov, B. Bieg, Zeszyty Naukowe 38(110), 27 (2014)

S. Ju et al., Nanotechnology. 18, 155201 (2007)

A. Borodin, M. Reichling, Phys. Chem. Chem. Phys. 13, 15442 (2011)

X. Gu, M. Zhang, F. Meng, X. Zhang, Y. Chen, S. Ruan, Appl. Surf. Sci. 307, 20–23 (2014)

C. Soci et al., Nano Lett. 7, 1003–1009 (2007)

A.M. Selman, Z. Hassan, M. Husham, N.M. Ahmed, Appl. Surf. Sci. 305, 445–452 (2014)

C. Lan, C. Li, Y. Yin, H. Guo, S. Wang, J. Mater. Chem. C. 3, 8074–8079 (2015)

O. Lupan, L. Chow, G. Chai, Sens. Actuator B 141, 511–517 (2009)

A.K. Yasutaka Takahashi, Jpn. J. Appl. Phys. 33, 6611–6615 (1994)

G.M. Ali, P. Chakrabarti, J. Phys. D. Appl. Phys. 43, 415103 (2010)

X. Kong, X. Sun, X. Li, Y. Li, Mater. Chem. Phys. 82, 997–1001 (2003)

A.G. Ardakani, M. Pazoki, S.M. Mahdavi, A.R. Bahrampour, N. Taghavinia, Appl. Surf. Sci. 258, 5405–5411 (2012)

N. Naderi, M.R. Hashim, J. Alloys Compd. 552, 356–362 (2013)

X. Kong, C. Liu, W. Dong, X. Zhang, C. Tao, L. Shen, J. Zhou, Y. Fei, S. Ruan, Appl. Phys. Lett. 94, 2007–2010 (2009)

N.K. Hassan, M.R. Hashim, N.K. Allam, Sens. Actuators A. 192, 124–129 (2013)

R. Shabannia, H. AbuHassan, H. Mahmodi, N. Naderi, H.R. Abd, Semicond. Sci. Technol. 28, 115007 (2013)

S. Xu, Z.L. Wang, Nano Res. 4, 1013–1098 (2011)

R. Shabannia, H.A. Hassan, Electron. Mater. Lett. 10, 837–843 (2014)

H. Endo et al., Appl. Phys. Lett. 90, 88–91 (2007)

B. Yuan, X.J. Zheng, Y.Q. Chen, B. Yang, T. Zhang, Solid. State. Electron. 55, 49–53 (2011)

M. Rajabi, R.S. Dariani, A. IrajiZad, Sens. Actuators A 180, 11–14 (2012)

S.P. Chang, C.Y. Lu, S.J. Chang, Y.Z. Chiou, T.J. Hsueh, C.L. Hsu, IEEE J. Sel. Top. Quantum Electron. 17, 990–995 (2011)

F. Yi, Q. Liao, X. Yan, Z. Bai, Z. Wang, X. Chen, Q. Zhang, Y. Huang, Y. Zhang, Physica E 61, 180–184 (2014)

J.S. Jie, W.J. Zhang, Y. Jiang, X.M. Meng, Y.Q. Li, S.T. Lee, Nano Lett. 6, 1887–1892 (2006)

R. Calarco, M. Marso, T. Richter, A.I. Aykanat, R. Meijers, A.V.D. Hart, T. Stoica, H. Lüth, Nano Lett. 5, 981–984 (2005)

S.H. Lee, S.H. Kim, J.S. Yu, Nanoscale Res. Lett. 11, 333 (2016)

C. Rodwihok, S. Choopun, P. Ruankham, A. Gardchareon, S. Phadungdhitidhada, D. Wongratanaphisan, Appl. Surf. Sci. (2017)

F.H. Alsultany, Z. Hassan, N.M. Ahmed, Opt. Mater. 60, 30–37 (2016)

Y. Yamanaka, T. Numai, K. Kasahara, K. Kuboto, Appl. Phys. Lett. 63, 1020–1022 (1993)

Acknowledgements

The author wishes to gratefully thank the University of Zakho, Kurdistan Region-Iraq for their support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdulrahman, A.F. The effect of different substrate-inclined angles on the characteristic properties of ZnO nanorods for UV photodetectors applications. J Mater Sci: Mater Electron 31, 14357–14374 (2020). https://doi.org/10.1007/s10854-020-03995-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03995-3