Abstract

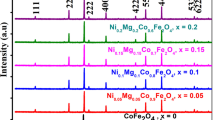

Heterogeneous Ni0.5Cu0.5−xZnxFe2O4 (0.0 ≤ x ≤ 0.5) nanoparticles are prepared via a green, solventless and additive-free, soft mechanochemical process at room temperature. This solid-state synthetic procedure yields ternary and quaternary oxide nanoparticles with uniform morphology (average particle size: 104–136 nm). X-ray diffraction analyses of Ni0.5Cu0.5−xZnxFe2O4 nanoparticles reveal a cubic spinel structure with crystallite size in the range of 24–31 nm. The lattice parameter (a) and hopping length for tetrahedral (LA) and octahedral (LB) lattice sites are found to increase with the increase in Zn2+ content, while X-ray (ρxrd) and bulk (ρbulk) densities decrease slightly due to increasing lattice volume. Ni0.5Cu0.5−xZnxFe2O4 nanoparticles with (x = 0.2, 0.3, 0.4) exhibit excellent dielectric performance with high permittivity (ε̍ = 92–111) and suppressed dielectric loss (ε̎ = 1.8–2.8) at high frequency (~ 106 Hz). The polarization mechanism is discussed, involving major contributions from the electron hopping (Fe2+ ↔ Fe3+) at the octahedral sites. The influence of Cu2+ and Zn2+ concentration on the cationic distribution and dielectric performance is analyzed. The electrical conductivity is found to follow the power law (σac = Aωn) with n = 0.7, which confirms the ac conduction phenomenon driven by the electron hopping mechanism. The dielectric behavior of Ni0.5Cu0.5−xZnxFe2O4 nanoparticles reveals their potential for applications in high-frequency microwave devices.

Similar content being viewed by others

References

N. Parsa, R.C. Toonen, IEEE Nanotechnol. Mag. 12, 28 (2018)

C. Stergiou, J. Magn. Magn. Mater. 426, 629 (2017)

D. Venkatesh, K.V. Ramesh, Mod. Phys. Lett. B 31, 1750318 (2017)

K.C.B. Naidu, S.R. Kiran, W. Madhuri, I.E.E.E. Trans, Magn. 53, 1 (2017)

H. Wang, Y. Song, X. Ye, H. Wang, W. Liu, L. Yan, ACS Appl. Energy Mater. 1, 3206 (2018)

B. Ren, Y. Huang, C. Han, M.N. Nadagouda, D.D. Dionysiou, in Ferrites and ferrates: chemistry and applications in sustainable energy and environmental remediation (ACS Publications, Washington, 2016), pp. 79–112

C.M. Park, Y.M. Kim, K.-H. Kim, D. Wang, C. Su, Y. Yoon, Chemosphere 221, 392 (2019)

R. Khurshid, F. Ali, A. Afzal, Z. Ali, M.T. Qureshi, J. Electrochem. Soc. 166, B258 (2019)

W. Ma, N. Wang, L. Yang, M. Lv, Z. Zhu, S. Li, J. Mater. Sci. Mater. Electron. (2020)

G. Gan, H. Zhang, Q. Li, J. Li, X. Huang, F. Xie, F. Xu, Q. Zhang, M. Li, T. Liang, J. Alloys Compd. 735, 2634 (2018)

Z. Zheng, X. Wu, Q. Feng, V.G. Harris, J. Am. Ceram. Soc. 103, 1248 (2020)

Q.Q. Wang, C.C. Wang, N. Zhang, H. Wang, Y.D. Li, Q.J. Li, S.G. Huang, Y. Yu, Y.M. Guo, Z.Q. Lin, J. Alloys Compd. 745, 401 (2018)

C. Rayssi, S. El-Kossi, J. Dhahri, K. Khirouni, RSC Adv. 8, 17139 (2018)

M.S. Bozgeyik, N. Kirkgecit, R.K. Katiyar, R.S. Katiyar, J. Alloys Compd. 819, 153050 (2020)

L. Lv, J.-P. Zhou, Q. Liu, G. Zhu, X.-Z. Chen, X.-B. Bian, P. Liu, Phys. E Low-Dimens. Syst. Nanostruct. 43, 1798 (2011)

S.E. Jacobo, P.G. Bercoff, Ceram. Int. 42, 7664 (2016)

L. Sun, R. Zhang, Z. Wang, L. Ju, E. Cao, Y. Zhang, J. Magn. Magn. Mater. 421, 65 (2017)

T.S. Soliman, A.S. Abouhaswa, J. Mater. Sci. Mater. Electron. 31, 9666 (2020)

T. Tsuzuki, P.G. McCormick, J. Mater. Sci. 39, 5143 (2004)

Z.Ž. Lazarević, Č. Jovalekić, A. Milutinović, D. Sekulić, V.N. Ivanovski, A. Rečnik, B. Cekić, N.Ž. Romčević, J. Appl. Phys. 113, 187221 (2013)

Z.Ž. Lazarević, Č. Jovalekić, A. Milutinović, D. Sekulić, M. Slankamenac, M. Romčević, N.Ž. Romčević, Ferroelectrics 448, 1 (2013)

Z.Ž. Lazarević, A.N. Milutinović, Č.D. Jovalekić, V.N. Ivanovski, N. Daneu, I. Mađarević, N.Ž. Romčević, Mater. Res. Bull. 63, 239 (2015)

C.H. Sujatha, K. Venugopal Reddy, K. Sowri Babu, A. Ramachandra Reddy, K.H. Rao, Ceram. Int. 39, 3077 (2013)

P.A. Jadhav, R.S. Devan, Y.D. Kolekar, B.K. Chougule, J. Phys. Chem. Solids 70, 396 (2009)

U. Holzwarth, N. Gibson, Nat. Nanotechnol. 6, 534 (2011)

M. Satalkar, S.N. Kane, J. Phys. Conf. Ser. 755, 012050 (2016)

M. Qayoom, R. Bhat, K. Asokan, M.A. Shah, G.N. Dar, J. Mater. Sci. Mater. Electron. 49, 1215 (2020)

I. Horcas, R. Fernández, J.M. Gómez-Rodríguez, J. Colchero, J. Gómez-Herrero, A.M. Baro, Rev. Sci. Instrum. 78, 013705 (2007)

S.M. Yunus, M.A. Asgar, F.U. Ahmed, Nucl. Sci. Appl. 8, 57 (1999)

M.C. Dimri, A. Verma, S.C. Kashyap, D.C. Dube, O.P. Thakur, C. Prakash, Mater. Sci. Eng. B 133, 42 (2006)

M. Hashim, S.E. Shirsath, S. Kumar, R. Kumar, A.S. Roy, J. Shah, R.K. Kotnala, J. Alloys Compd. 549, 348 (2013)

W.M. Haynes, CRC Handbook of Chemistry and Physics, 94th edn. (CRC Press, Boca Raton, 2016)

M.I.A. Abdel Maksoud, G.S. El-Sayyad, M. Abd Elkodous, A.S. Awed, J. Mater. Sci. Mater. Electron. 31, 2598 (2020)

M. Dhiman, M. Tripathi, S. Singhal, Mater. Chem. Phys. 202, 40 (2017)

A.R. Chavan, J.S. Kounsalye, R.R. Chilwar, S.B. Kale, K.M. Jadhav, J. Alloys Compd. 769, 1132 (2018)

B. Yang, Z. Wang, J. Sol-Gel Sci. Technol. 80, 840 (2016)

T.M. Hammad, J.K. Salem, A.A. Amsha, N.K. Hejazy, J. Alloys Compd. 741, 123 (2018)

M. Manjurul Haque, M. Huq, M.A. Hakim, Phys. B Condens. Matter 404, 3915 (2009)

A.V. Raut, R.S. Barkule, D.R. Shengule, K.M. Jadhav, J. Magn. Magn. Mater. 358–359, 87 (2014)

K.C.B. Naidu, W. Madhuri, Int. J. Appl. Ceram. Technol. 13, 1090 (2016)

R. Kumar, M. Kar, Ceram. Int. 42, 6640 (2016)

W. Rasband, ImageJ 1.52a: image processing and analysis in java (National Institute of Health, Bethesda, 2020)

S.C. Watawe, B.D. Sarwade, S.S. Bellad, B.D. Sutar, B.K. Chougule, J. Magn. Magn. Mater. 214, 55 (2000)

Y.J. Li, X.M. Chen, R.Z. Hou, Y.H. Tang, Solid State Commun. 137, 120 (2006)

I. Sadiq, S. Naseem, M. Naeem Ashiq, M.A. Khan, S. Niaz, M.U. Rana, Prog. Nat. Sci. Mater. Int. 25, 419 (2015)

N.-N. Jiang, Y. Yang, Y.-X. Zhang, J.-P. Zhou, P. Liu, C.-Y. Deng, J. Magn. Magn. Mater. 401, 370 (2016)

S.U. Haque, K.K. Saikia, G. Murugesan, S. Kalainathan, J. Alloys Compd. 701, 612 (2017)

M.A. Almessiere, B. Unal, Y. Slimani, A. Demir Korkmaz, N.A. Algarou, A. Baykal, Results Phys. 14, 102468 (2019)

K.M. Batoo, M.S. Ansari, Nanoscale Res. Lett. 7, 112 (2012)

A. Verma, O.P. Thakur, C. Prakash, T.C. Goel, R.G. Mendiratta, Mater. Sci. Eng. B 116, 1 (2005)

S.S. Bellad, B.K. Chougule, Mater. Chem. Phys. 66, 58 (2000)

R.M. Cornell, U. Schwertmann, The iron oxides: structure, properties, reactions, occurrences and uses (Wiley, New York, 2003)

B.M. Greenhoe, M.K. Hassan, J.S. Wiggins, K.A. Mauritz, J. Polym. Sci. Part B Polym. Phys. 54, 1918 (2016)

N. Rezlescu, E. Rezlescu, Phys. Status Solidi A 23, 575 (1974)

P.S. Liu, G.F. Chen, Porous materials: processing applications (Butterworth-Heinemann, Boston, 2014), pp. 21–112

G.T. Rado, H. Suhl, Spin arrangements and crystal structure, domains, and micromagnetics: a treatise on modern theory and materials (Academic Press, Cambridge, 2013)

Q. Zhang, G. Chen, G. Dong, G. Zhang, X. Liu, J. Qiu, Q. Zhou, Q. Chen, D. Chen, Chem. Phys. Lett. 482, 228 (2009)

M.F. Al-Hilli, S. Li, K.S. Kassim, Mater. Chem. Phys. 128, 127 (2011)

T. Krishnaveni, B.R. Kanth, V.S.R. Raju, S.R. Murthy, J. Alloys Compd. 414, 282 (2006)

B.I. Kharisov, O.V. Kharissova, U. Ortiz-Mendez, CRC concise encyclopedia of nanotechnology (CRC Press, Boca Raton, 2016)

Acknowledgements

The authors would like to acknowledge the support provided by King AbdulAziz City for Science and Technology (KACST) through the Science and Technology Unit at King Fahd University of Petroleum and Minerals (KFUPM) for this work through project No.13-NAN467-04 as part of the National Science, Technology, and Innovation Plan. AA and FAA are grateful to SB Waje and MA Atieh for their help in the characterization of samples and discussions of the outcomes.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Afzal, A., Abuilaiwi, F.A., Javaid, R. et al. Solid-state synthesis of heterogeneous Ni0.5Cu0.5-xZnxFe2O4 spinel oxides with controlled morphology and tunable dielectric properties. J Mater Sci: Mater Electron 31, 14261–14270 (2020). https://doi.org/10.1007/s10854-020-03982-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03982-8