Abstract

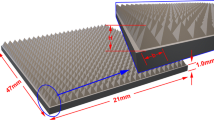

Polymers filled with conductive carbon black allow for the 3D printing of electrically conductive samples. The resistivity of these 3D printed samples depends on both the microscopic parameters of the carbon black filler and also on the macroscopic arrangement of the extrudites that build up the 3D printed sample. To investigate this dependence, we characterize the resistivity of five different printing infill patterns and find that a cross-ply pattern, which has extrudites oriented both in the direction of current flow and perpendicular to the direction of current flow has a lower resistivity of \(0.229\,\Omega {\text{m}}\) than the resistivity of \(0.458\,\Omega {\text{m}}\) found for a uni-ply pattern with all extrudites oriented in the direction of current flow. A Monte Carlo simulation of a large network of variable resistors illustrates the feasibility that the lower resistivity of the cross-ply pattern is caused by cross-flow which diverts current around areas of high local resistance. The same type of 3D printed conductive samples are tested as electromagnetic shields at frequencies up to 3.0 GHz using a custom-designed flanged coaxial sample holder. The shielding effectiveness of three sample infill patterns and four sample infill densities is compared. Cross-ply and angle-ply samples show the most efficient shielding effectiveness (normalized to sample density) of \(17.5\,{\text{dB}}/{\text{g}}\,{\text{cm}}^{3}\) at an infill density of 50% and would be the infill pattern of choice in an application constrained by weight or material.

Similar content being viewed by others

References

Proto-Pasta, Electrically conductive composite PLA, https://www.proto-pasta.com/products/conductive-pla?variant=1265211476. Accessed 15 July 2020

Amolen, 3d printer filament, conductive black PLA filament, https://amolen.com/products/amolen-3d-printer-filament-conductive-black-pla-filament-500g1-1lb. Accessed 15 July 2020

S.J. Leigh, R.J. Bradley, C.P. Purssell, D.R. Billson, D.A. Hutchins, PLoS ONE 7(11), e49365 (2012). https://doi.org/10.1371/journal.pone.0049365

Z. Manzoor, M.T. Ghasr, K.M. Donnell, in 2018 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) (2018). https://doi.org/10.1109/i2mtc.2018.8409627

K. Chizari, M. Arjmand, Z. Liu, U. Sundararaj, D. Therriault, Mater. Today Commun. 11, 112 (2017). https://doi.org/10.1016/j.mtcomm.2017.02.006

S. Dul, L. Fambri, A. Pegoretti, Nanomaterials 8(1), 49 (2018). https://doi.org/10.3390/nano8010049

W. Zhang, A.A. Dehghani-Sanij, R.S. Blackburn, J. Mater. Sci. 42(10), 3408 (2007). https://doi.org/10.1007/s10853-007-1688-5

M. Narkis, A. Vaxman, J. Appl. Polym. Sci. 29(5), 1639 (1984). https://doi.org/10.1002/app.1984.070290518

H. Watschke, K. Hilbig, T. Vietor, Appl. Sci. 9(4), 779 (2019). https://doi.org/10.3390/app9040779

H.L. Tekinalp, V. Kunc, G.M. Velez-Garcia, C.E. Duty, L.J. Love, A.K. Naskar, C.A. Blue, S. Ozcan, Compos. Sci. Technol. 105, 144 (2014). https://doi.org/10.1016/j.compscitech.2014.10.009

H.H. Bin-Hamzah, O. Keattch, D. Covill, B.A. Patel, Sci. Rep. 8, 1 (2018). https://doi.org/10.1038/s41598-018-27188-5

J. Zhang, B. Yang, F. Fu, F. You, X. Dong, M. Dai, Appl. Sci. 7(1), 20 (2017). https://doi.org/10.3390/app7010020

Proto-pasta, Cdp1xxxx safety data sheet, https://cdn.shopify.com/s/files/1/0717/9095/files/CDP1xxxx_SDS.pdf?1992606272897634343. Accessed 15 July 2020

J. Rommes, W.H.A. Schilders, IEEE Trans. Comput. Aided Des. Integr. Circ. Syst. 29(1), 28 (2010). https://doi.org/10.1109/tcad.2009.2034402

R. Valente, C. De Ruijter, D. Vlasveld, S. Van Der Zwaag, P. Groen, IEEE Access 5, 16665 (2017). https://doi.org/10.1109/access.2017.2741527

C. Holloway, M. Sarto, M. Johansson, IEEE Trans. Electromagn. Compat. 47(4), 833 (2005). https://doi.org/10.1109/temc.2005.854101

E. Huber, M. Mirzaee, J. Bjorgaard, M. Hoyack, S. Noghanian, I. Chang, in 2016 IEEE International Conference on Electro Information Technology (EIT) (2016). https://doi.org/10.1109/eit.2016.7535340

A.J. McDowell, T. Hubing, Decomposition of Shielding Effectiveness into Absorption and Reflection Components. Technical Report (Clemson University, Clemson, 2016)

D. Schmitz, L. Ecco, S. Dul, E. Pereira, B. Soares, G. Barra, A. Pegoretti, Mater. Today Commun. 15, 70 (2018). https://doi.org/10.1016/j.mtcomm.2018.02.034

Acknowledgements

The authors acknowledge the Minnesota Supercomputing Institute (MSI) at the University of Minnesota for providing resources that contributed to the research results reported within this paper. http://www.msi.umn.edu.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Truman, L., Whitwam, E., Nelson-Cheeseman, B.B. et al. Conductive 3D printing: resistivity dependence upon infill pattern and application to EMI shielding. J Mater Sci: Mater Electron 31, 14108–14117 (2020). https://doi.org/10.1007/s10854-020-03965-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03965-9