Abstract

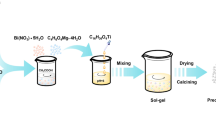

Effects of different sintering atmospheres (O2 and air) on the energy storage properties and dielectric characteristics were systematically investigated for 2MgO–2Al2O3–5SiO2 (MAS)-coated Er0.02Sr0.97TiO3 (EST) ceramics. The core–shell structure was formed by the sol-precipitation method. The ceramic sintered in O2 features fine grain, excellent frequency stability, low leakage current, high dielectric breakdown strength (BDS), and high energy storage density (Wreco). Compared with air-sintered ceramics, the dielectric DC breakdown strength of ceramic sintered in oxygen atmosphere has been enhanced significantly from 375 to 590 kV/cm. Besides, the maximum Wreco of 2.01 J/cm3 and efficiency of 86.2% were obtained at 460 kV/cm, which demonstrated that the core–shell structure and atmosphere sintering provide an instructive strategy for the design of high energy storage materials.

Similar content being viewed by others

References

Z.H. Yao, Z. Song, H. Hao, Z.Y. Yu, M. Cao, S. Zhang, M.T. Lanagan, H.X. Liu, Adv. Mater. 29, 1601727 (2017)

V.S. Puli, D.K. Pradhan, D.B. Chrisey, M. Tomozawa, J. Mater. Sci. 48, 2151 (2013)

H.B. Yang, F. Yan, Y. Lin, T. Wang, ACS Sustain. Chem. Eng. 5, 10215 (2017)

M.H. Park, H.J. Kim, Y.J. Kim, T. Moon, K.D. Kim, C.S. Hwang, Adv. Energy Mater. 16, 1400610 (2014)

D.E. Grupp, A.M. Goldman, Science 18, 276 (1997)

N. Wang, H.J. Chen, H.C. He, W. Norimatsu, M. Kusunoki, K. Koumoto, Sci. Rep. 3, 3449 (2013)

T.K. Townsend, N.D. Browning, ACS Nano 6, 7420 (2012)

D.L. He, Y. Wang, X.Q. Chen, Y. Deng, Compos. Part A Appl. Sci. Manuf. 93, 137 (2017)

X.D. Huang, H.X. Liu, S.J. Zhang, G.Y. Li, H. Hao, M.H. Cao, Z.H. Yao, J. Xie, J. Mater. Sci. Mater. Electron. 29, 11546 (2018)

Z.C. He, M.H. Cao, L. Zhou, L. Zhang, J. Xie, S.J. Zhang, J.L. Qi, H. Hao, Z.H. Yao, Z.Y. Yu, H.X. Liu, J. Am. Ceram. Soc. 101, 5089 (2018)

Z.C. He, M.H. Cao, Y. Tao, Y.Y. Suo, Q. Luo, H. Hao, Z.H. Yao, Z.Y. Yu, H.X. Liu, J. Phys. Chem. C 123, 18142 (2019)

D. Zhang, T.W. Button, V.O. Sherman, A.K. Tagantsev, T. Price, D. Iddles, J. Eur. Ceram. Soc. 30, 407 (2010)

T. Takada, S.F. Wang, S. Yoshikawa, S.J. Jang, R.E. Newnham, J. Am. Ceram. Soc. 77, 2485 (1994)

K. Chen, Y.P. Pu, N. Xu, X. Luo, J. Mater. Sci. Mater. Electron. 23, 1599 (2012)

K.C. Li, H. Wang, H.F. Zhou, M.H. Zhang, X. Yao, Int. J. Appl. Ceram. Technol. 7, E144 (2010)

E.P. Gorzkowski, M.J. Pan, B. Bender, C.C.M. Wu, J. Electroceram. 18, 269 (2007)

J.J. Shyu, J.R. Wang, J. Am. Ceram. Soc. 83, 3135 (2000)

Y.C. Zhang, X.H. Wang, J.Y. Kim, Z.B. Tian, J. Fang, K.H. Hur, L. Li, J. Am. Ceram. Soc. 95, 1628 (2012)

M. Rong, C. Bin, Y.J. Wang, S.Y. Wang, Y.Y. Wang, Mater. Res. Bull. 111, 311 (2019)

F.Z. Zeng, M.H. Cao, L. Zhang, M. Liu, H. Hao, Z.H. Yao, H.X. Liu, Ceram. Int. 43, 7710 (2017)

B. Johar, H. Mohamad, Z.A. Ahmad, Int. J. Appl. Ceram. Technol. 8, 637 (2011)

A. Benhammou, Y.E. Hafiane, L. Nibou, A. Yaacoubi, J. Soro, A. Smith, J.P. Bonnet, B. Tanouti, Ceram. Int. 39, 21 (2013)

A. Tkach, O. Okhay, A. Almeida, P.M. Vilarinho, Acta Mater. 130, 249 (2017)

X. Zhao, W. Chen, L.X. Zhang, J.H. Gao, L.S. Zhong, Appl. Phys. A 118, 931 (2015)

W. Chen, X. Zhao, J. Sun, L.X. Zhong, L.S. Zhong, J. Alloys Compd. 670, 48 (2016)

M. Liu, M.H. Cao, F.Z. Zeng, J.L. Qi, H.X. Liu, H. Hao, Z.H. Yao, Ceram. Int. 44, 20239 (2018)

B.B. Liu, X.H. Wang, R.X. Zhang, L.T. Li, J. Alloy. Compd. 691, 619 (2017)

W.G. Pan, M.H. Cao, C.L. Diao, C. Tao, H. Hao, Z.H. Yao, Z.Y. Yu, H.X. Liu, J. Mater. Sci. 54, 12401 (2019)

P.L. Yuan, D.B. Li, L. Shi, Ceram. Int. 45, 12594 (2019)

X.L. Deng, Z.X. Zeng, R.C. Xu, X.F. Qin, X.X. Li, Y.Q. Wang, R.L. Gao, Z.H. Wang, G. Chen, W. Cai, C.L. Fu, J. Mater. Sci. Mater. Electron. 30, 16502 (2019)

S.K. Pradhan, B.K. Roul, Phys. B 407, 2527 (2012)

B.B. Liu, X. Wang, Q. Zhao, J. Am. Ceram. Soc. 98, 2641 (2015)

T. Wang, L. Jin, L.L. Shu, Q.Y. Hu, X.Y. Wei, J. Alloys Compd. 617, 399 (2014)

Q.M. Zhang, L. Wang, J. Luo, Q. Tang, J. Du, J. Am. Ceram. Soc. 92, 1871 (2009)

Acknowledgements

This work was supported by National Natural Science Foundation of China (NO. 51872213), the National Key Basic Research Program of China (973 Program NO. 2015CB654601), the Fundamental Research Funds for the Central Universities (NO. 195101007), Technical Innovation Special Program of Hubei Province (NO. 2017AHB055), China Scholarship Council (201906950070) and State Key Laboratory of Advanced Technology for Materials Synthesis and Processing (Wuhan University of Technology).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fang, Y., Cao, M., He, Z. et al. High breakdown strength and energy storage density of Er0.02Sr0.97TiO3@MgO2–Al2O3–SiO2 ceramics with core–shell structure sintered in oxygen atmosphere. J Mater Sci: Mater Electron 31, 13408–13414 (2020). https://doi.org/10.1007/s10854-020-03895-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03895-6