Abstract

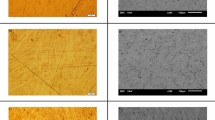

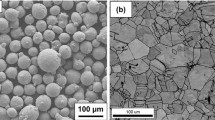

Sn–58Bi–1Ag solder ribbon was prepared by twin-roll rapid solidification technology, and the ultrasonic soldering process was used to prepare Cu/Sn–58Bi–1Ag/Cu linear solder joints. Electron probe microanalysis (EPMA) and energy dispersive X-ray spectroscopy (EDS) were used to study the interface morphology of intermetallic compounds (IMC), Bi segregation, and solder joint matrix microstructure evolution with the current density of 1 × 104A/cm2 (25 °C). The result shows that the morphology of the anode IMC layer changes from scallop-like to hilly-like and then to flat-plate-like with the electrification time, and the thickness of IMC layer increases gradually. Bi is segregated toward the anode to form a Bi-rich layer. The cathode IMC layer is changed from a scallop to a zigzag, and its thickness is firstly increased and then decreased. The Sn is segregated toward the cathode to finally form a β-Sn-rich layer. Coarsening of eutectic microstructure (β-Sn+Bi) in solder joint matrix was caused by prolonged time. Based on linear fitting, the kinetic index n of the IMC layer of the anode and cathode is 0.432 and 0.491, respectively, and the growth mechanism is supposed to be volume diffusion. Ultrasonic soldering techniques can refine the Bi phase and increase the solubility of Bi in β-Sn, which slows down the formation of Bi-rich layers. The addition of Ag forms wedge-shaped and granular Ag3Sn intermetallic compounds, which hinders the growth of the Bi-rich layer and the Cu6Sn5 IMC, thus effectively inhibiting the electromigration process.

Similar content being viewed by others

References

Q. Zhang, H. Zou, Z. Zhang, Improving tensile and fatigue properties of Sn–58Bi/Cu solder joints through alloying substrate. J. Mater. Res. 25(2), 303–314 (2010)

X. Zhao, M. Saka, M. Muraoka et al., Electromigration behaviors and effects of addition elements on the formation of a Bi-rich layer in Sn58Bi-based solders. J. Electron. Mater. 43(11), 4179–4185 (2014)

M. Lu, D.Y. Shih, P. Lauro et al., Effect of Sn grain orientation on electromigration degradation mechanism in high Sn-based Pb-free solders. Appl. Phys. Lett. 92(21), 1335 (2008)

K. Lee, K.S. Kim, Y. Tsukada et al., Effects of the crystallographic orientation of Sn on the electromigration of Cu/Sn–Ag–Cu/Cu ball joints. J. Mater. Res. 114(3), 467–474 (2011)

W. Yue, H. Qin, M. Zhou et al., Electromigration induced microstructure evolution and damage in asymmetric Cu/Sn-58Bi/Cu solder interconnect under current stressing. Trans. Nonferrous Met. Soc. China 24(5), 1619–1628 (2014)

J. Xu, M. Xiang, B. Dang et al., Relation of cooling rate, undercooling and structure for rapid solidification of iron melt. Comput. Mater. Sci. 128, 98–102 (2017)

R.M. Shalaby, Effect of rapid solidification on mechanical properties of a lead free Sn–3.5Ag solder. J. Alloys Compd. 505(1), 113–117 (2010)

S. Liu, T. Song, W. Xiong et al., Effects of Ag on the microstructure and shear strength of rapidly solidified Sn–58Bi solder. J. Mater. Sci.: Mater. Electron. 30(7), 6701–6707 (2019)

F. Wang, D. Li, S. Tian et al., Interfacial behaviors of Sn-Pb, Sn-Ag-Cu Pb-free and mixed Sn-Ag-Cu/Sn-Pb solder joints during electromigration. Microelectron. Reliab. 73, 106–115 (2017)

H. He, H. Zhao, F. Guo, et al., Bi layer formation at the anode interface in Cu/Sn-58Bi/Cu solder joints with high current density. J. Mater. Sci. Technol. 28(1), 46–52 (2012)

C. Chen, C. Huang, Atomic migration in eutectic SnBi solder alloys due to current stressing. J. Mater. Res. 23(4), 1051–1056 (2008)

K.N. Tu, D. Gupta, Electromigration in stressed metal thin films. Defect Diffus. Forum 95–98, 257–262 (1993)

H.W. He, Mechanism investigation of Bi layer formation at anode interface in Cu/Sn-58Bi/Cu solder joint induced by electromigration. Trans. China Weld. Inst. 31(10), 35–38 (2010)

Acknowledgements

This research was supported by National Natural Science Foundation of China (Grant No. 51475345). The authors would like to express thanks to Hubei Provincial Natural Science Foundation of China, China (Grant No. 2018CFB212).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, S., Liu, Z., Liu, L. et al. Electromigration behavior of Cu/Sn–58Bi–1Ag/Cu solder joints by ultrasonic soldering process. J Mater Sci: Mater Electron 31, 11997–12003 (2020). https://doi.org/10.1007/s10854-020-03817-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03817-6