Abstract

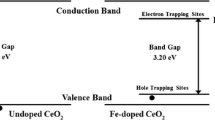

Thin films of pure and Pd-doped CeO2 with different doping concentrations deposited via sol gel spin coating technique. The influence of Pd doping level (0, 2, 4 and 8%) on the physical characteristics was investigated of nanocrystalline CeO2 thin films. From X-ray diffraction (XRD) pattern, the (111) preferred oriented CeO2 cubic structure was observed in all thin films. Crystallite size decreased with increasing Pd doping from 67.41 to 41.67 nm, whereas the crystallinity of thin film increased with doping level. The field emission scanning electron microscopy (FESEM) analyses showed the uniform distribution of nanospherical grains, decreased in size and agglomerated of nanocrystallite with increasing Pd doping. Energy-dispersive X-ray (EDX) results revealed that the weight percentage of un-doped and Pd-doped CeO2 thin films was confirmed and very close to that in mixed precursor. The energy bandgap values of prepared thin films were measured as a function of Pd doping centration using UV–Vis spectroscopy. Energy bandgap as well as the transmission of CeO2 were increased with Pd doping level. The PL spectra show noticeable variations in intensity and red shift of the emission peaks upon Pd doping. These effects have been associated with structural modifications and defect states Pd-doped CeO2 thin films. The Nyquist plots suggest that the ionic conductivity through the grains is responsible in the conduction mechanism of the thin films.

Similar content being viewed by others

References

M. Venkateshan, C.B. Fitzgerald, J.M.D. Coey, Nature 430, 630 (2004)

H. Ohno, Science 281, 951 (1998)

U. Lampe, J. Gerblinger, H. Meixner, Sens. Actuators B 7, 787–791 (1992)

M. Yamashita, K. Kameyama, S. Yabe, S. Yoshida, Y. Fujishiro, T. Kawai, T. Sato, J. Mater. Sci. Lett. 37, 683 (2002)

R. Di Maggio, S. Rossi, L. Fedrizzi, P. Scardi, Surf. Coat. Technol. 89, 292 (1997)

R. Aguiar, F. Sanchez, C. Ferrater, M. Varela, Thin Solid Films 306, 74 (1997)

C.S. Oh, C.I. Kim, K.H. Kwon, J. Vac. Sci. Technol. A19, 1068 (2001)

A.M. Salvi, F. Decker, F. Varsano, G. Speranze, Surf. Interface Anal. 31, 255 (2001)

J.J. Roa, E. Giliolib, F. Bissoli, F. Pattini, S. Rampino, X.G. Capdevila, M. Segarra, Thin Solid Films 518, 227–232 (2009)

I. Szab, B. Nagy, G. Volksch, W. Holand, J. NonCryst, Solids 272, 191–199 (2000)

Y.S. Touloukian, R.K. Kirby, R.E. Taylor, P.D. Desai, Thermophysical properties of Matter Thermal Expansion (Metallic Elements and Alloys), vol. 12 (IFI/PLENUM, New York, 1977), p. 77

N. Ozer, Solar Energy Mater Solar Cells 68, 391–400 (2001)

B. Vodungbo, Y. Zheng, F. Vidal, D. Demaille, V.H. Etgens, D.H. Mosca, Appl. Phys. Lett. 90, 062510 (2007)

V. Fernandes, J.J. Klein, N. Mattoso, D.H. Mosca, E. Silveira, E. Ribeiro, W.H. Schreiner, J. Varalda, A.J.A. de Oliveira, Phys. Rev. B 75, 121304(R) (2007)

Q.Y. Wen, H.W. Zhang, Y.Q. Song, Q.H. Yang, H. Zhu, J.Q. Xiao, J. Phys.: Condens. Matter 19, 246205 (2007)

S. Debnath, M.R. Islam, M.S.R. Khan, Bull. Mater. Sci. 30, 315–319 (2007)

W. Xiaodong, L. Qing, W. Duan, J. Rare Earths 24, 549–553 (2006)

X. Zhang, J. Wei, H. Yang, X. Liu, W. Liu, C. Zhang, Y. Yang, Eur. J. Inorg. Chem. 2013, 4443–4449 (2013)

J. Tan, W. Zhang, Y.H. Lv, A.L. Xia, Mater. Res. 16, 689–694 (2013)

G. Hass, J.B. Ramsaay, R. Thun, J. Opt. Soc. Am. 48, 324 (1958)

D. Keomany, J.P. Pettit, D. Deroo, SPIE Proc. 2255, 513 (1994)

I. Porqueras, C. Person, C. Corbella, M. Vives, A. Pinyol, E. Bertran, Solid State Ionics 165, 131–137 (2003)

B. Tatar, E.D. Sam, K. Kutlu, M. Urgen, J. Mater. Sci. 43, 5102–5108 (2008)

A. Hartridge, M. Ghanashyam Krishna, A.K. Bhattacharya, J. Phys. Chem. Solids 59(6–7), 859–866 (1998)

M. Oikawa, S. Fujihara, J. Eur. Ceram. Soc. 25, 2921–2924 (2005)

X. Multone, Y. Luo, P. Hoffmann, Mater. Sci. Eng. B 146, 35–40 (2008)

R.D. Shannon, Acta Crystallogr. A 32, 751–765 (1976)

F.A. Al-Agel, E. Al-Arfaj, A.A. Al-Ghamdi, Y. Losovyj, L.M. Bronstein, W.E. Mahmoud, J. Magn. Magn. Mater. 360, 73–79 (2014)

H.P. Klug, L.E. Alexander, X-Ray Diffraction Procedures, 2nd edn. (Wiley, New York, 1974), pp. 687–703

S.M. Ali, S.M. Ramaya, N.U. Rehman, T.S. Al Khuraiji, M.A. Shar, A. Mahmood, A. Hassan, M. Riaz, Mater. Sci. Semicond. Process. 93, 44–49 (2019)

A. Sundaresan, R. Bhargavi, N. Rangarajan, U. Siddesh, C.N.R. Rao, Phys. Rev. B. 74, 161306 (2006)

M.Y. Ge, H. Wang, E.Z. Liu, J.F. Liu, J.Z. Jiang, Y.K. Li, Z.A. Xu, H.Y. Li, Appl. Phys. Lett. 93, 062505 (2008)

R.J.V. Overstraeten, R.P. Mertens, Heavy doping effects in silicon. Solid State Electron. 30, 1077–1087 (1987)

C. Mansilla, Solid State Sci. 11, 1456–1464 (2009)

Y.M. Hao, S.H. Lou, S.M. Zhou, R.J. Yuan, G.Y. Zhu, N. Li, Nanoscale Res. Lett. 7, 1–9 (2012)

S. Phokha, S. Pinitsoontorn, S. Maensiri, J. Appl. Phys. 112, 113904 (2012)

F. Meng, C. Zhang, Z. Fan, J. Gong, A. Li, Z. Ding, H. Tang, M. Zhang, G. Wu, J. Alloy. Comp. 647, 1013–1021 (2015)

P.P. Murmu, R.J. Mendelsberg, J. Kennedy, D.A. Carder, B.J. Ruck, A. Markwitz, R.J. Reeves, P. Malar, T. Osipowicz, J. Appl. Phys. 110, 033534 (2011)

L. Zang, Energy Efficiency and Renewable, Energy Through Nanotechnology (Springer-Verlag, London, 2011), p. 803

T. Suzuki, I. Kosacki, H.U. Anderson, Solid State Ionics 151, 111 (2002)

U. Rammelt, G. Reinhard, Electrochim. Acta 40, 505–511 (1995)

G. Perrier, R. Bettignies, S. Berson, N. Lemaître, S. Guillerez, Sol. Energy Mater. Sol. Cells 101, 210 (2012)

J.B. Jorcin, M.E. Orazem, N. Pébère, B. Tribollet, Electrochim. Acta 51, 1473 (2006)

A. Hassan, M. Muhyuddin, A. Rahman, M. Usman, M.A. Basit, S.W. Husain, J Mater. Sci. 31, 2625–2633 (2020)

M. Muhyuddin, M.T. Ahsan, I. Ali, T.F. Khan, M.A. Akram, M.A. Basite, Appl. Phys. A 125, 716 (2019)

Acknowledgements

This work was supported by King Saud University, Deanship of Scientific Research, and College of Science Research Center.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ali, S.M., Khan, S.UD., AlGarawi, M.S. et al. Tuning of structural, optical, and impedance properties of CeO2 thin films by incorporation palladium ions. J Mater Sci: Mater Electron 31, 10031–10037 (2020). https://doi.org/10.1007/s10854-020-03547-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03547-9