Abstract

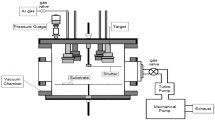

In this study, we optimised the molybdenum (Mo) back-contact layer for solar cell applications on stainless steel substrates using direct-current (dc) sputtering with varying sputtering powers (100 W to 500 W) and pressures (5 mTorr to 20 mTorr). We comparatively analysed the effectiveness of titanium (Ti) layer deposited using e-beam evaporation deposition and zinc oxide (ZnO) layer deposited using radio-frequency (RF) sputtering for barrier application with Mo. Structural characterisation of the optimised Mo films was carried out using XRD studies confirmed the (110) plane corresponding to the body-centred cubic (bcc) structure. Estimated Mo film parameters for films deposited on barrier layers were compared against films deposited on SS substrate without any barriers as these properties influence the prospective diffusion of Fe and Cr into the absorber layer. Surface characterisation of the deposited films was carried out using a scanning electron microscopy (SEM) to study the morphology of films, and energy-dispersive X-ray (EDX) to identify elemental presence to confirm the blockage of the impurities atoms through the film. Secondary ion mass spectroscopy (SIMS) was employed to study the depth profiles of films while atomic force microscopy (AFM) was used to characterise the topographical properties from the sputtered Mo film and analyse the grain properties of the films. A low resistivity value of 0.511 × 10–6 Ω m for Mo films on the reference glass substrate and 0.625 × 10–6 Ω m for the Mo film on ZnO barrier was measured using the four-point probe. We observed a further 40% reduction in impurities using annealed ZnO barrier combined with an optimised Mo layer.

Similar content being viewed by others

References

U.S. EIA, Annual Energy Outlook 2019 with projections to 2050, Annu. Energy Outlook 2019 with Proj. to 2050. (2019).

International Renewable Energy Agency, Renewable Power Generation Costs in 2018, (2019). https://doi.org/10.1007/SpringerReference_7300.

A. International Energy, Renewables information 2004, IEA Stat. (2004), https://doi.org/10.1787/9789264099531-en.

G. Lomax, M. Workman, T. Lenton, N. Shah, Reframing the policy approach to greenhouse gas removal technologies. Energy Policy. (2015). https://doi.org/10.1016/j.enpol.2014.10.002

C. Paulson, Greenhouse Gas Control Technologies. In Proceedings of the 5th International Conference on Greenhouse Gas Control Technologies (2019). https://doi.org/10.1071/9780643105027.

K.S. Lackner, CLIMATE CHANGE: A guide to CO2 sequestration. Science (2003). https://doi.org/10.1126/science.1079033

J. Kemper, Biomass and carbon dioxide capture and storage: a review. Int. J. Greenh. Gas Control. (2015). https://doi.org/10.1016/j.ijggc.2015.06.012

L.J. Cseke, S.D. Wullschleger, A. Sreedasyam, G. Trivedi, P.E. Larsen, F.R. Collart, in Carbon sequestration, ed. by L.J. Cseke Genomics and Breeding for Climate-Resilient Crops, vol. 2 (Springer, Berlin, 2013) https://doi.org/10.1007/978-3-642-37048-9_12.

G.D. Soni, Advantages of green technology. Soc. Issue Environ. Probl. 39035(9), 1–5 (2014)

National Renewable Energy Laboratory, Learning About Renewable Energy, https://www.Nrel.Gov. (2017)

F.V. Bekun, A.A. Alola, S.A. Sarkodie, Toward a sustainable environment: Nexus between CO2 emissions, resource rent, renewable and nonrenewable energy in 16-EU countries. Sci. Total Environ. (2019). https://doi.org/10.1016/j.scitotenv.2018.12.104

M. Guarnieri, M. Liserre, T. Sauter, J.Y. Hung, Future energy systems: Integrating renewable energy sources into the smart power grid through industrial electronics. IEEE Ind. Electron. Mag. (2010). https://doi.org/10.1109/MIE.2010.935861

M. Beaudin, H. Zareipour, A. Schellenberglabe, W. Rosehart, Energy storage for mitigating the variability of renewable electricity sources: An updated review. Energy Sustain. Dev. (2010). https://doi.org/10.1016/j.esd.2010.09.007

R. Foster, M. Ghassemi, A. Cota, A Solar Energy: Renewable Energy and the Environment, (CRC Press, Boca Raton, 2010)

J. Mohtasham, Review article-renewable energies. Energy Procedia 74, 1289–1297 (2015). https://doi.org/10.1016/j.egypro.2015.07.774

A. González, E. Goikolea, J.A. Barrena, R. Mysyk, Review on supercapacitors: Technologies and materials. Renew. Sustain. Energy Rev. (2016). https://doi.org/10.1016/j.rser.2015.12.249

M. Beaudin, H. Zareipour, A. Schellenberg, W. Rosehart, Energy storage for mitigating the variability of renewable electricity sources. Energy Storage Smart Grids Plan. Oper. Renew. Var. Energy Resour. 2014. 14, 1–33 https://doi.org/10.1016/B978-0-12-410491-4.00001-4

M.S. Guney, Y. Tepe, Classification and assessment of energy storage systems. Renew. Sustain. Energy Rev. (2017). https://doi.org/10.1016/j.rser.2016.11.102

T. Kim, J.-H. Kim, T.E. Kang, C. Lee, H. Kang, M. Shin, C. Wang, B. Ma, U. Jeong, T.-S. Kim, B.J. Kim, Flexible, highly efficient all-polymer solar cells. Nat. Commun. 6, 8547 (2015). https://doi.org/10.1038/ncomms9547

R. Wuerz, A. Eicke, M. Frankenfeld, F. Kessler, M. Powalla, P. Rogin, O. Yazdani-Assl, CIGS thin-film solar cells on steel substrates. Thin Solid Films 517, 2415–2418 (2009). https://doi.org/10.1016/j.tsf.2008.11.016

Y. Galagan, Flexible solar cells, in Roll-to-Roll Manufacturing: Process Elements and Recent Advances, ed. by Y. Galagan, et al. (Wiley, Hoboken, 2018), pp. 325–362

S. Teraji, J. Chantana, T. Watanabe, T. Minemoto, Development of flexible Cd-free Cu(In, Ga)Se2 solar cell on stainless steel substrate through multi-layer precursor method. J. Alloys Compd. 756, 111–116 (2018). https://doi.org/10.1016/j.jallcom.2018.05.024

K. Sun, F. Liu, J. Huang, C. Yan, N. Song, H. Sun, C. Xue, Y. Zhang, A. Pu, Y. Shen, J.A. Stride, M. Green, X. Hao, Flexible kesterite Cu2 ZnSnS4 solar cells with sodium-doped molybdenum back contacts on stainless steel substrates. Sol. Energy Mater. Sol. Cells. (2018). https://doi.org/10.1016/j.solmat.2018.02.036

S. Zhang, Y. Qin, J. Zhu, J. Hou, Over 14% efficiency in polymer solar cells enabled by a chlorinated polymer donor. Adv. Mater. (2018). https://doi.org/10.1002/adma.201800868

Q. Luo, H. Ma, Q. Hou, Y. Li, J. Ren, X. Dai, Z. Yao, Y. Zhou, L. Xiang, H. Du, H. He, N. Wang, K. Jiang, H. Lin, H. Zhang, Z. Guo, All-carbon-electrode-based endurable flexible perovskite solar cells. Adv. Funct. Mater. (2018). https://doi.org/10.1002/adfm.201706777

C. Roldán-Carmona, O. Malinkiewicz, A. Soriano, G. Mínguez Espallargas, A. Garcia, P. Reinecke, T. Kroyer, M.I. Dar, M.K. Nazeeruddin, H.J. Bolink, Flexible high efficiency perovskite solar cells. Energy Environ. Sci. 7, 994–997 (2014). https://doi.org/10.1039/c3ee43619e

Y. Galagan, D.J.D. Moet, D.C. Hermes, P.W.M. Blom, R. Andriessen, Large area ITO-free organic solar cells on steel substrate. Org. Electron. Physics, Mater. Appl. 13, 3310–3314 (2012). https://doi.org/10.1016/j.orgel.2012.09.039

S.J. Lee, Y.H. Chen, S.C. Hu, Y.C. Lin, J.W. Chang, T.L. Poon, W.C. Ke, Improved performance of amorphous Si thin-film solar cells on 430 stainless steel substrate by an electrochemical mechanical polishing process. J. Alloys Compd. 558, 95–98 (2013). https://doi.org/10.1016/j.jallcom.2013.01.044

F. Kessler, D. Rudmann, Technological aspects of flexible CIGS solar cells and modules. Sol. Energy 77, 685–695 (2004). https://doi.org/10.1016/j.solener.2004.04.010

S. Niki, M. Contreras, I. Repins, M. Powalla, K. Kushiya, S. Ishizuka, K. Matsubara, CIGS absorbers and processes. Prog. Photovolt. Res. Appl. 18, 453–466 (2010). https://doi.org/10.1002/pip.969

W.-S. Liu, H.-C. Huaan, N.-W. Puaa, S.-C. Liang (2014) Using a Ti/TiN composite structure as the diffusion barrier layer for CIGS solar cell application on stainless, in 2014 21st Int. Work. Act. Flatpanel Displays Devices, IEEE, pp. 245–248. https://doi.org/10.1109/AM-FPD.2014.6867182

W.S. Liu, H.C. Hu, N.W. Pu, S.C. Liang, Developing flexible CIGS solar cells on stainless steel substrates by using Ti/TiN composite structures as the diffusion barrier layer. J. Alloys Compd. 631, 146–152 (2015). https://doi.org/10.1016/j.jallcom.2014.12.189

C.Y. Shi, Y. Sun, Q. He, F.Y. Li, J.C. Zhao, Cu(In, Ga)Se2 solar cells on stainless-steel substrates covered with ZnO diffusion barriers. Sol. Energy Mater. Sol. Cells. 93, 654–656 (2009). https://doi.org/10.1016/j.solmat.2008.12.004

D. Bae, S. Kwon, J. Oh, J. Lee, W. Kim, Fabrication of high efficiency flexible CIGS solar cell with ZnO diffusion barrier on stainless steel substrate. Mater. Res. Soc. Symp. Proc. 1324, 115–120 (2012). https://doi.org/10.1557/opl.2011.966

D. Bae, S. Kwon, J. Oh, W.K. Kim, H. Park, Investigation of Al2O3 diffusion barrier layer fabricated by atomic layer deposition for flexible Cu(In, Ga)Se2 solar cells. Renew. Energy 55, 62–68 (2013). https://doi.org/10.1016/j.renene.2012.12.024

K.-B. Kim, Effect of metal barrier layer for flexible solar cell devices on tainless steel substrates. Appl. Sci. Converg. Technol. 26, 16–19 (2017). https://doi.org/10.5757/asct.2017.26.1.16

P. Blösch, F. Pianezzi, A. Chirilǎ, P. Rossbach, S. Nishiwaki, S. Buecheler, A.N. Tiwari, Diffusion barrier properties of molybdenum back contacts for Cu(In, Ga)Se2 solar cells on stainless steel foils. J. Appl. Phys. 113, 054506 (2013). https://doi.org/10.1063/1.4789616

C.-W. Kim, H.J. Kim, J.H. Kim, C. Jeong, Characterization of flexible CIGS thin film solar cells on stainless steel with intrinsic ZnO diffusion barriers. J. Nanosci. Nanotechnol. 16, 5124–5127 (2016). https://doi.org/10.1166/jnn.2016.12198

K. Herz, A. Eicke, F. Kessler, R. Wächter, M. Powalla, Diffusion barriers for CIGS solar cells on metallic substrates. Thin Solid Films 431–432, 392–397 (2003). https://doi.org/10.1016/S0040-6090(03)00259-1

X. Hu, Z. Song, W. Liu, F. Qin, Z. Zhang, H. Wang, Chemical mechanical polishing of stainless steel foil as flexible substrate. Appl. Surf. Sci. 258, 5798–5802 (2012). https://doi.org/10.1016/j.apsusc.2012.02.100

L. Jiang, Y. He, Y. Yang, J. Luo, Chemical mechanical polishing of stainless steel as solar cell substrate. ECS J. Solid State Sci. Technol. 4, P162–P170 (2015). https://doi.org/10.1149/2.0171505jss

O. Nwakanma, P. Reyes, S. Velumani, Electrical, structural, and topographical properties of direct current (DC) sputtered bilayer molybdenum thin films. J. Mater. Sci. Mater. Electron. 29, 15671–15681 (2018). https://doi.org/10.1007/s10854-018-9165-2

K. Sun, F. Liu, J. Huang, C. Yan, N. Song, H. Sun, C. Xue, Y. Zhang, A. Pu, Y. Shen, J.A. Stride, M. Green, X. Hao, Flexible kesterite Cu2ZnSnS4 solar cells with sodium-doped molybdenum back contacts on stainless steel substrates. Sol. Energy Mater. Sol. Cells. 182, 14–20 (2018). https://doi.org/10.1016/j.solmat.2018.02.036

W.J. Lee, D.H. Cho, J.H. Wi, W.S. Han, J. Kim, Y.D. Chung, Na effect on flexible Cu(In, Ga)Se2 photovoltaic cell depending on diffusion barriers (SiOx, i-ZnO) on stainless steel. Mater. Chem. Phys. 147, 783–787 (2014). https://doi.org/10.1016/j.matchemphys.2014.06.021

G.L. Agawane, S.W. Shin, S.A. Vanalakar, M.P. Suryawanshi, A.V. Moholkar, J.H. Kim, Investigations on chemo-mechano stabilities of the molybdenum thin films deposited by DC-sputter technique. Zeitschrift Fur Phys. Chemie. (2015). https://doi.org/10.1515/zpch-2014-0624

S.M. Pandharkar, S.R. Rondiya, A.V. Rokade, B.B. Gabhale, H.M. Pathan, S.R. Jadkar, Synthesis and characterization of molybdenum back contact using direct current-magnetron sputtering for thin film solar cells. Front. Mater. (2018). https://doi.org/10.3389/fmats.2018.00013

R.F. Bunshah, Handbook of Deposition Technolgies for Films and Coatings (William Andrew, Amsterdam, 1994)

P.M. Martin, Handbook of Depositions Tecnologies for Film and coating (William Andrew, Amsterdam, 2005)

J.J. Cras, C.A. Rowe-Taitt, D.A. Nivens, F.S. Ligler, Comparison of chemical cleaning methods of glass in preparation for silanization. Biosens. Bioelectron. 14, 683–688 (1999). https://doi.org/10.1016/S0956-5663(99)00043-3

D.M. Mattox, Deposition (PVD) Processing Second edition Dedication To my wife Vivienne (William Andrew, Amsterdam, 2009)https://doi.org/10.1016/B978-0-8155-2037-5.00025-3

A. Maldonado, M. dela Luzolvera, Deposition and characterization of ultrathin intrinsic zinc oxide (i-ZnO) films by radio frequency (RF) sputtering for propane gas sensing application. J. Mater. Sci. Mater. Electron. 29, 15682–15692 (2018). https://doi.org/10.1007/s10854-018-9166-1

V. Uvarov, I. Popov, Metrological characterization of X-ray diffraction methods at different acquisition geometries for determination of crystallite size in nano-scale materials. Mater. Charact. 85, 111–123 (2013). https://doi.org/10.1016/j.matchar.2013.09.002

F. Nemla, D. Cherrad, Metallic amorphous electrodeposited molybdenum coating from aqueous electrolyte: Structural, electrical and morphological properties under current density. Appl. Surf. Sci. 375, 1–8 (2016). https://doi.org/10.1016/j.apsusc.2016.01.012

S.K. Ghosh, T. Bera, O. Karacasu, A. Swarnakar, J.G. Buijnsters, J.P. Celis, Nanostructured MoSx-based thin films obtained by electrochemical reduction. Electrochim. Acta. (2011). https://doi.org/10.1016/j.electacta.2010.10.065

G.K. Williamson, R.E. Smallman III, Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. (1956). https://doi.org/10.1080/14786435608238074

S. Velumani, S.K. Narayandass, D. Mangalaraj, Structural characterization of hot wall deposited cadmium selenide thin films. Semicond. Sci. Technol. (1998). https://doi.org/10.1088/0268-1242/13/9/009

R.J. MacDonald, B.V. King, SIMS—Secondary Ion Mass Spectrometry (Springer, New York, 2003), pp. 127–154. https://doi.org/10.1007/978-3-662-05227-3_5

Z.H. Li, E.S. Cho, S.J. Kwon, Molybdenum thin film deposited by in-line DC magnetron sputtering as a back contact for Cu(In, Ga)Se2 solar cells. Appl. Surf. Sci. (2011). https://doi.org/10.1016/j.apsusc.2011.06.101

W. Li, X. Yan, A.G. Aberle, S. Venkataraj, Effect of deposition pressure on the properties of magnetron-sputter-deposited molybdenum back contacts for CIGS solar cells. Jpn. J. Appl. Phys. 54, 08KC14 (2015). https://doi.org/10.7567/JJAP.54.08KC14

J.H. Scofield, A. Duda, D. Albin, B.L. Ballard, P.K. Predecki, Sputtered molybdenum bilayer back contact for copper indium diselenide-based polycrystalline thin-film solar cells. Thin Solid Films 260, 26–31 (1995). https://doi.org/10.1016/0040-6090(94)06462-8

H. Windischmann, R.W. Collins, J.M. Cavese, Effect of hydrogen on the intrinsic stress in ion beam sputtered amorphous silicon films. J. Non. Cryst. Solids. 85, 261–272 (1986). https://doi.org/10.1016/0022-3093(86)90001-3

I. Blech, U. Cohen, Effects of humidity on stress in thin silicon dioxide films. J. Appl. Phys. 53, 4202–4207 (1982). https://doi.org/10.1063/1.331244

T. Yamaguchi, R. Miyagawa, Effects of oxygen on the properties of sputtered molybdenum thin films. Jpn. J. Appl. Phys. 30, 2069–2073 (1991). https://doi.org/10.1143/JJAP.30.2069

E. Weber, H.G. Riotte, Iron as a thermal defect in silicon. Appl. Phys. Lett. 33, 433–435 (1978). https://doi.org/10.1063/1.90412

H.J. Rijks, J. Bloem, L.J. Giling, Heat treatment of silicon and the nature of thermally induced donors. J. Appl. Phys. 50, 1370–1374 (1979). https://doi.org/10.1063/1.326117

S. Sintonen, P. Kivisaari, S. Pimputkar, S. Suihkonen, T. Schulz, J.S. Speck, S. Nakamura, Incorporation and effects of impurities in different growth zones within basic ammonothermal GaN. J. Cryst. Growth. 456, 43–50 (2016). https://doi.org/10.1016/j.jcrysgro.2016.08.040

Y. Kim, M.S. Kim, H.J. Yun, S.Y. Ryu, B.J. Choi, Effect of growth temperature on AlN thin films fabricated by atomic layer deposition. Ceram. Int. 44, 17447–17452 (2018). https://doi.org/10.1016/j.ceramint.2018.06.212

H. Zhao, J. Xie, A. Mao, A. Wang, Y. Chen, T. Liang, D. Ma, Effects of heating mode and temperature on the microstructures, electrical and optical properties of molybdenum thin films. Materials (Basel). 11, 1634 (2018). https://doi.org/10.3390/ma11091634

D. Rafaja, H. Köstenbauer, U. Mühle, C. Löffler, G. Schreiber, M. Kathrein, J. Winkler, Effect of the deposition process and substrate temperature on the microstructure defects and electrical conductivity of molybdenum thin films. Thin Solid Films 528, 42–48 (2013). https://doi.org/10.1016/j.tsf.2012.06.087

J.-H. Cha, K. Ashok, N.J.S. Kissinger, Y.-H. Ra, J.-K. Sim, J.-S. Kim, C.-R. Lee, Effect of thermal annealing on the structure, morphology, and electrical properties of mo bottom electrodes for solar cell applications. J. Korean Phys. Soc. 59, 2280–2285 (2011). https://doi.org/10.3938/jkps.59.2280

B. Rajesh Kumar, T. Subba Rao, AFM studies on surface morphology, topography and texture of nanostructured zinc aluminum oxide thin films. Dig. J. Nanomater. Biostruct. 7, 1881–1889 (2012).

M.M. Aqil, M.A. Azam, M.F. Aziz, R. Latif, Deposition and characterization of molybdenum thin film using direct current magnetron and atomic force microscopy. J. Nanotechnol. 2017, 1–4 (2017). https://doi.org/10.1155/2017/4862087

B. Bhushan, Surface roughness analysis and measurement techniques. in: B. Bhushan (ed) Modern Tribology Handbook. CRC Press, Boca Raton, 2000.

A. Sedky, T.A. El-Brolossy, S.B. Mohamed, Correlation between sintering temperature and properties of ZnO ceramic varistors. J. Phys. Chem. Solids. (2012). https://doi.org/10.1016/j.jpcs.2011.11.035

D.S. McPhail, Applications of secondary ion mass spectrometry (SIMS) in materials science. J. Mater. Sci. 41, 873–903 (2006). https://doi.org/10.1007/s10853-006-6568-x

Acknowledgements

We wish to acknowledge Consejo Nacional de Ciencia y Tecnología y la Secretaría de Energía (CONACyT-SENER) (Project 263043) and El Centro Mexicano de Innovacíon en Energía Solar (CEMIE-Sol P-55) for the financial support for this project. We also wish to acknowledge Miguel Angel Avendaño (AFM), Francisco Alvarado Cesar (SEM measurements), Norma Iris González García (e-beam evaporation), M. en C. Adolfo Tavira Fuentes (XRD measurements), and Ing. Miguel Ángel Luna Arias (thickness measurements) for their technical support. Also, A.M and O.N thank CONACyT for the scholarship opportunities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Morán, A., Nwakanma, O., Velumani, S. et al. Comparative study of optimised molybdenum back-contact deposition with different barriers (Ti, ZnO) on stainless steel substrate for flexible solar cell application. J Mater Sci: Mater Electron 31, 7524–7538 (2020). https://doi.org/10.1007/s10854-020-03058-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03058-7