Abstract

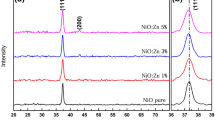

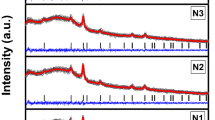

Codoped Fe–Ni zinc oxide (ZnO:Fe:Ni) thin films have been deposited successfully on bare soda-lime glass substrates by the ultrasonic chemical spray technique. Zinc acetylacetonate hydrate was selected as Zn source and nickel acetylacetonate and iron chloride as doping sources. Structural, morphological, and optical characterizations were done for ZnO:Fe:Ni films. The location of the X-ray diffraction peaks of the undoped ZnO films corresponds to wurtzite hexagonal type with the (002) plane normally perpendicular to the substrate surface; however, for codoped ZnO films, the corresponding diffraction peaks fit well to the wurtzite hexagonal type. Moreover, a peak with preferential orientation in the 2θ position of 38° and another low intensity peak located at 61° corresponding to bcc cubic structure of Fe3O4 were observed. Dramatic changes in the surface morphology in accordance with the doping level were observed for codoped ZnO films. The gas sensing response of undoped and codoped ZnO films was tested with propane and carbon monoxide gases and found to be moderate at low concentrations and significant for higher concentrations.

Similar content being viewed by others

References

A.K. Radzimska, T. Jesionowski, Materials 7, 2833 (2014)

S. Chaudhary, A. Umar, Nanosci. Nanotechnol. Lett. 9, 1787 (2017)

S.U. Jen, H. Sun, H.P. Chiang, Materials 9, 987 (2016)

S. Sugumaran, C.S. Bellan, D. Bheeman, Opt. Mater. 72, 618 (2017)

V. Craciun, R.K. Singh, J. Perriere, J. Spear, D. Craciund, J. Electrochem. Soc. 147, 1077 (2000)

S. Kim, C. Kim, J.N. Jihoon, J. Sol Gel Sci. Technol. 74, 790 (2018)

S. Jongthammanurak, T. Cheawkul, M. Witana, Thin Solid Films 571, 114 (2014)

D. Perednis, L.J. Gauckler, J. Electroceram. 14, 103 (2005)

C. Guild, S. Biswas, Y. Meng, T. Jafari, A.M. Gaffney, S.L. Suib, Catal. Today 238, 87 (2017)

S.V. Roth, J Phys Condens. Mater. 28, 1 (2016)

M. Boshta, E. Chikoidze, M.H. Sayed, C. Vilar, B.Y. Berini, J. Mater. Sci. 49, 7943 (2014)

A. Srivastava, N. Kumar, S. Khare, Opto-Electron Rev. 22, 68 (2014)

W. Bousslama, H. Elhouichet, M. Férid, Optik 134, 88 (2017)

N.V. Kaneva, D.T. Dimitrov, C.D. Dushkin, Appl. Surf. Sci. 257, 8113 (2011)

G.K. Mani, J.B.B. Rayappan, Appl. Surf. Sci. 311, 405 (2014)

V.V. Ganbavle, S.I. Inamdar, G.L. Agawane, J.H. Kim, K.Y. Rajpure, Chem. Eng. J. 286, 36 (2016)

A.M. Al-Hamdia, U. Rinner, M. Sillanpää, Process Saf. Environ. 107, 190 (2017)

P. Samarasekara, N.U.S. Yapa, N.T.R.N. Kumara, M.V.K. Perera, Bull. Mater. Sci. 30, 113 (2007)

C.Y. Lu, S.P. Chang, S.J. Chang, T.J. Hsueh, C.L. Hsu, Y.Z. Chiou, I.C. Chen, IEEE Sens. J. 9, 485 (2009)

R. Kumar, O.A. Dossary, G. Kumar, A. Umar, Nano-micro Lett. 7, 97 (2015)

B. Yuliarto, M.F. Ramadhani, N. Tapran, N.L.W. Septiani, K. Hamam, J. Mater. Sci. 52, 4543 (2017)

M. Hjiri, R. Dhahri, R. Dhahri, K. Omri, E.M.M. Lassaad, S.G. Leonardi, N. Donato, G. Neri, Mater. Sci. Semicond. Proc. 27, 319 (2014)

V.K. Jayaraman, A. Maldonado, M. Olvera, Mater. Lett. 157, 169 (2015)

H. Gómez-Pozos, E.J. Luna-Arredondo, A. Maldonado, R. Biswal, Y. Kudriavtsev, J. Vega-Pérez, Y.L. Casallas-Moreno, M. Olvera, Materials (2016). https://doi.org/10.3390/ma9020087

R.L. Fomekong, D. Lahem, M. Debliquyd, S. Yunus, J.L. Ngolui, A. Delcorte, Sens. Actuator B 231, 520 (2016)

V.R. Shinde, T.P. Gujar, C.D. Lokhande, Sens. Actuators B 123, 701 (2007)

N.L. Tarwal, A.V. Rajgure, J.Y. Patil, M.S. Khandekar, S.S. Suryavanshi, P.S. Patil, M.G. Gang, J.H. Kim, J.H. Jang, J. Mater. Sci. 48, 7274 (2013)

G.K. Mani, J.B.B. Rayappan, Mater. lett. 158, 373 (2015)

J.W. Orton, M.J. Powell, Rep. Prog. Phys. 43, 1263 (1980)

J.Y.W. Seto, J. Appl. Phys. 46, 5247 (1975)

W. Wu, Z. Wu, T. Yu, C. Jiang, W.S. Kim, Sci. Technol. Adv. Mater. 16, 1 (2015)

M.P. Dasari, U. Godavarti, V.D. Mote, Process Appl. Ceram. 12, 100 (2018)

B.D. Cullity, Elements of X-ray Diffraction, 1st edn. (Addison Wesley, Reading, 1956), pp. 96–102

C.S. Barret, T.B. Massalski, Structure of Metals: Crystallographic Methods, Principles and Data (Pergamon Press, Oxford, 1980), p. 204

Z.R. Khan, M. Zulfequar, M.S. Khan, Mater. Lett. 174, 145 (2010)

A.P. Roth, W.J. Keeler, E. Fortin, Can. J. Phys. 58, 560 (1980)

E. Burstein, Anomalous optical absorption limit in InSb. Phys Rev. 93, 632 (1954)

M. Grundmann, The Physics of Semiconductors (Springer, Berlin, 2006)

A. Smith, R. Rodriguez-Clemente, Thin Solid Films 345, 192 (1999)

R. Jaaniso, O.K. Tan, Semiconductor Gas Sensors (Chap. 2) (Woodhead Publishing, Cambridge, 2013)

A. Gregory, Baxes, Digital Image Processing, Principles and Applications (Wiley, New York, 1994)

Acknowledgments

Authors would like to thank Moises Orduño-Gómez, E. J. Luna-Arredondo, M. A. Luna-Arias, A. Tavira-Fuentes, and J.E. Romero-Ibarra for their technical assistance. This work was partially supported by Programa de Mejoramiento del Profesorado from the Secretaria de Educación Pública, México.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jayaraman, V.K., Biswal, R.R., Hernandez, A.G. et al. Synthesis and characterization of chemically sprayed ZnO:Fe:Ni thin films: effect of codoping concentration and response as gas sensor. J Mater Sci: Mater Electron 31, 7423–7433 (2020). https://doi.org/10.1007/s10854-020-02938-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-02938-2