Abstract

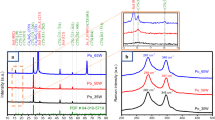

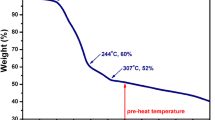

CuSbS2 thin films were fabricated by spray pyrolysis from metal chloride aqueous solutions, followed by a post-deposition sulfurization step. The structural, chemical, optical and electrical properties of CuSbS2 and the effect of various sulfurization temperatures on CuSbS2 thin film have been systematically studied. We used a two-step sulfurization method. Step 1 at lower temperature was to encourage complete saturation of the as-deposited film with sulfur vapor. And step 2 at higher temperature was to promote the formation and crystallization of CuSbS2. The sulfurization temperature of step 2 is very important for the formation of device-grade CuSbS2 films. With the increase in sulfurization temperature, impurities such as Sb2S3 decreased and the crystallinity of CuSbS2 improved. Until 400 °C, impurities disappeared and phase-pure well-crystallinity CuSbS2 thin films were obtained. When the sulfurization temperature is higher than 400 °C, CuSbS2 gradually changes to Cu3SbS4. The CuSbS2 films sulfurized at 400 °C with optimum band gap of 1.53 eV are p type, and absorption coefficient is larger than 105 cm−1 in the visible light wavelength range. The temperature dependence of electrical conductivity of CuSbS2 has been studied for the first time. At measurement temperatures higher than 140 K the electrical conductivity of the CuSbS2 film is dominated by band conduction and nearest neighbor hopping (NNH). However, at temperatures below 140 K the conduction is predominantly affected by variable range hopping (VRH). Finally, thin-film solar cells based on the sprayed CuSbS2 absorber layers with a maximum photoelectric conversion efficiency of 0.34% have been fabricated.

Similar content being viewed by others

References

F.W. de Souza Lucas, A. Zakutayev, APL Mater. 6, 084501 (2018)

J. Zhou, G.-Q. Bian, Q.-Y. Zhu, Y. Zhang, C.-Y. Li, J. Dai, J. Solid State Chem. 182, 259–264 (2009)

A.C. Rastogi, N.R. Janardhana, Thin Solid Films 565, 285–292 (2014)

T. Rath, A.J. MacLachlan, M.D. Brown, S.A. Haque, J. Mater. Chem. A 3, 24155–24162 (2015)

I. Grigas, N.N. Mozgova, A. Orlyukas, V. Samulenis, Sov. Phys. Crystallogr. 20, 741–742 (1976)

A. Nagaoka, K. Yoshino, Growth of CZTS single crystals, in Copper Zinc Tin Sulfide-based Thin-film Solar Cells, ed. by K. Ito (Wiley, West Sussex, 2015), pp. 135–137

S. Adachi, Physical properties: compiled experimental data, in Copper Zinc Tin Sulfide-Based Thin-Film Solar Cells, ed. by K. Ito (Wiley, West Sussex, 2015), pp. 152–155

W. Septina, S. Ikeda, Y. Iga, T. Harada, M. Matsumura, Thin Solid Films 550, 700–704 (2014)

A.W. Welch, L.L. Baranowski, P. Zawadzki, C. DeHart, S. Johnston, S. Lany, C.A. Wolden, A. Zakutayev, Prog. Photovoltaics Res. Appl. 24, 929–939 (2016)

F.W. de Souza Lucas, A.W. Welch, L.L. Baranowski, P.C. Dippo, H. Hempel, T. Unold, R. Eichberger, B. Blank, U. Rau, L.H. Mascaro, A. Zakutayev, J. Phys. Chem. C 120, 18377–18385 (2016)

A.D. Saragih, D.-H. Kuo, T.T.A. Tuan, J. Mater. Sci. 28, 2996–3003 (2017)

S. Banu, S.J. Ahn, S.K. Ahn, K. Yoon, A. Cho, Sol. Energy Mater. Sol. Cells 151, 14–23 (2016)

B. Yang, L. Wang, J. Han, Y. Zhou, H. Song, S. Chen, J. Zhong, L. Lv, D. Niu, J. Tang, Chem. Mater. 26, 3135–3143 (2014)

Y. Xu, Q. Ye, W. Chen, X. Pan, L. Hu, S. Yang, T. Hayat, A. Alsaedi, J. Zhu, S. Dai, J. Mater. Sci. 53, 2016–2025 (2018)

L. Wan, C. Ma, K. Hu, R. Zhou, X. Mao, S. Pan, L.H. Wong, J. Xu, J. Alloys Compd. 680, 182–190 (2016)

M.I. Medina-Montes, E. Campos-González, M. Morales-Luna, T.G. Sánchez, M. Becerril-Silva, S.A. Mayén-Hernández, F. de Moure-Flores, J. Santos-Cruz, Mater. Sci. Semicond. Process. 80, 74–84 (2018)

Y. Rodríguez-Lazcano, M.T.S. Nair, P.K. Nair, J. Electrochem. Soc. 152, G635 (2005)

B. Krishnan, S. Shaji, R. Ernesto Ornelas, J. Mater. Sci. Mater. Electron. 26, 4770–4781 (2015)

C. Macías, S. Lugo, Á. Benítez, I. López, B. Kharissov, A. Vázquez, Y. Peña, Mater. Res. Bull. 87, 161–166 (2017)

V. Vinayakumar, S. Shaji, D. Avellaneda, T.K. Das Roy, G.A. Castillo, J.A.A. Martinez, B. Krishnan, Sol. Energy Mater. Sol. Cells 164, 19–27 (2017)

S.C. Riha, A.A. Koegel, J.D. Emery, M.J. Pellin, A.B.F. Martinson, A.C.S. Appl, Mater. Interfaces 9, 4667–4673 (2017)

S. Liu, L. Chen, L. Nie, X. Wang, R. Yuan, Chalcogenide Lett. 11, 639–644 (2014)

I. Popovici, A. Duta, Int J Photoenergy. (2012). https://doi.org/10.1155/2012/962649

C.J. Hibberd, E. Chassaing, W. Liu, D.B. Mitzi, D. Lincot, A.N. Tiwari, Prog. Photovoltaics Res. Appl. 18, 434–452 (2010)

A.T. Barrows, A.J. Pearson, C.K. Kwak, A.D.F. Dunbar, A.R. Buckley, D.G. Lidzey, Energy Environ. Sci. 7, 2944–2950 (2014)

R. Zhou, Z. Yang, J. Xu, G. Cao, Coord. Chem. Rev. 374, 279–313 (2018)

F. Aziz, A.F. Ismail, Mater. Sci. Semicond. Process. 39, 416–425 (2015)

S.S. Chen, L. Brown, M. Levendorf, W.W. Cai, S.Y. Ju, J. Edgeworth, X.S. Li, C.W. Magnuson, A. Velamakanni, R.D. Piner, J.Y. Kang, J. Park, R.S. Ruoff, ACS Nano 5, 1321–1327 (2011)

R.E. Ornelas-Acosta, D. Avellaneda, S. Shaji, G.A. Castillo, T.K. Das Roy, B. Krishnan, J. Mater. Sci. Mater. Electron. 25, 4356–4362 (2014)

G.H. Albuquerque, K.-J. Kim, J.I. Lopez, A. Devaraj, S. Manandhar, Y.-S. Liu, J. Guo, C.-H. Chang, G.S. Herman, J. Mater. Chem. A 6, 8682–8692 (2018)

J.Y.W. Seto, J. Appl. Phys. 46, 5247–5254 (1975)

S.K. Swami, N. Chaturvedi, A. Kumar, V. Dutta, Sol. Energy 122, 508–516 (2015)

F.W. de Souza Lucas, H. Peng, S. Johnston, P.C. Dippo, S. Lany, L.H. Mascaro, A. Zakutayev, J. Mater. Chem. A 5, 21986 (2017)

J.C. Gonzalez, G.M. Ribeiro, E.R. Viana, P.A. Fernandes, P.M.P. Salome, K. Gutierrez, A. Abelenda, F.M. Matinaga, J.P. Leitao, A.F. da Cunha, J. Phys. D 46, 155107 (2013)

D.K. Paul, S.S. Mitra, Phys. Rev. Lett. 31, 1000–1003 (1973)

Acknowledgements

This work was financially supported by the Fundamental Research Funds for the Central Universities (No. JZ2017HGTB0192), the National Natural Science Foundation of China (Nos. 51302057, 51602088), the Natural Science Foundation of Anhui Province (Nos. 1608085QE92, 1708085MA11) and the Hefei University of Technology 2018 Training Program of Innovation for Undergraduates (Nos. 2018CXCY092, 2018CXCY114).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, L., Guo, X., Fang, Y. et al. Spray pyrolysis deposited CuSbS2 absorber layers for thin-film solar cells. J Mater Sci: Mater Electron 30, 21485–21494 (2019). https://doi.org/10.1007/s10854-019-02531-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02531-2