Abstract

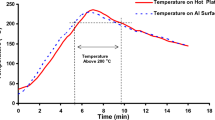

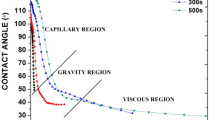

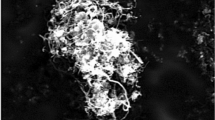

This paper investigates the effects of Cu substrate annealing on the wettability of Sn–3.0Cu lead-free solder and the subsequent growth of the intermetallic compounds that are formed at the interface between the solder and the substrate. The annealing processes yielded various grain sizes, grain orientations, and residual strains within the substrates. Then, effects of the Cu substrates on the wetting and intermetallic formation were studied via reflow soldering using Sn–3.0Cu lead-free solder. The annealed substrates were compared to an unannealed Cu reference at soldering times of 20, 40, 60 and 120 s. The experimental results demonstrated that the substrate grain orientation, residual strain and grain size exert no influence on the solder wettability. After soldering, only a η-Cu6Sn5 intermetallic compound was observed in the interfacial layer for both the reference and annealed copper substrates. The thickness of the η-Cu6Sn5 layer was found to be independent of the substrate grain size but increased as the misorientation angle and the residual strain in the substrate increased.

Similar content being viewed by others

Data availability

The raw/processed data that are required for reproducing these findings cannot be shared at this time as the data also constitute part of an ongoing study.

References

F.Y. Ouyang, Y.P. Su, J. Alloy. Compd. 655, 155 (2016)

Q.K. Zhang, W.M. Long, Z.F. Zhang, J. Alloy. Compd. 646, 405 (2015)

H. Nishikawa, N. Iwata, J. Mater. Process. Technol. 215, 6 (2015)

J. Koo, J. Chang, Y.W. Lee, S.J. Hong, K.-S. Kim, H.M. Lee, J. Alloy. Compd. 608, 126 (2014)

M.J. Rizvi, C. Bailey, Y.C. Chan, M.N. Islam, H. Lu, J. Alloy. Compd. 438, 122 (2007)

A. Sharif, Y.C. Chan, Mater. Sci. Eng., B 106, 126 (2004)

T. Laurila, V. Vuorinen, J.K. Kivilahti, Mater. Sci. Eng. 49, 1 (2005)

G.K. Sujan, A.S.M.A. Haseeb, A.B.M. Afifi, Mater. Charact. 97, 199 (2014)

P.J. Shang, Z.Q. Liu, D.X. Li, J.K. Shang, J. Electron. Mater. 38, 2579 (2009)

R. Zhang, Y. Tian, B. Liu, C. Hang, in 2013 14th International Conference On Electronic Packaging Technology (ICEPT) (IEEE, 2013), pp. 1276–1279

J.O. Suh, K.N. Tu, J. Appl. Phys. 102, 1 (2007)

K.N. Tu, Solder Joint Technology (Springer, New York, 2007)

O.M. Abdelhadi, L. Ladani, J. Alloy. Compd. 537, 87 (2012)

J. Shen, Y.C. Chan, S.Y. Liu, Acta Mater. 57, 5196 (2009)

M. Schaefer, R.A. Fournelle, J. Liang, J. Electron. Mater. 27, 1167 (1998)

K. Cao, K. Tan, C. Lai, L. Zhang, in 2009 International Conference on Electronic Packaging Technology & High Density Packaging (IEEE, 2009), pp. 819–823

R. Abbaschian, R.E. Reed-Hill, Physical Metallurgy Principles (Cengage Learning, Boston, 2008)

P.T. Lee, Y.S. Wu, P.C. Lin, C.C. Chen, W.Z. Hsieh, C.E. Ho, Surf. Coat. Technol. 320, 559 (2017)

Y.J. Li, C. Chen, in Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), 2016 11th International (IEEE, 2016), pp. 42–44

J.M. Wang, K.J. Wang, J.G. Duh, J. Electron. Mater. 40, 1549 (2011)

M.L. Huang, F. Yang, Sci. Rep. 4, 7117 (2014). https://doi.org/10.1038/srep07117

P. Shen, Z. Yin, J. Yang, J. Sun, Z. Jiang, Q. Jiang, Surf. Interface Anal. 42, 1681 (2010)

B.J. Lee, N.M. Hwang, H.M. Lee, Acta Mater. 45, 1867 (1997)

E. Chauvet, P. Kontis, E.A. Jägle, B. Gault, D. Raabe, C. Tassin, J.J. Blandin, R. Dendievel, B. Vayre, S. Abed, Acta Mater. 142, 82 (2018)

B.B. Straumal, B.S. Bokshtein, A.B. Straumal, A.L. Petelin, JETP Lett. 88, 537 (2008)

A.S. Gornakova, B.B. Straumal, S. Tsurekawa, L.S. Chang, A.N. Nekrasov, Rev. Adv. Mater. Sci. 21, 18 (2009)

E. Rabkin, I. Snapiro, Acta Mater. 48, 4463 (2000)

ASTM, in ASTM International E 112-12 (2012), pp. 1–27

L.A.I. Kestens, H. Pirgazi, Mater. Sci. Technol. 32, 1303 (2016)

C.E. Ho, C.C. Chen, M.K. Lu, Y.W. Lee, Y.S. Wu, Surf. Coat. Technol. 303, 86 (2016)

M.R. Akbarpour, M. Farvizi, H.S. Kim, Mater. Des. 119, 311 (2017)

D.P. Field, L.T. Bradford, M.M. Nowell, T.M. Lillo, Acta Mater. 55, 4233 (2007)

D. Yadav, R. Bauri, Mater. Sci. Technol. 31, 494 (2015)

N. Bozzolo, A. Agnoli, N. Souaï, M. Bernacki, R.E. Logé, Mater. Sci. Forum 753, 321 (2013)

O. Glushko, M.J. Cordill, Scr. Mater. 130, 42 (2017)

Z.D. Jastrzebski, The Nature of Properties of Engineering Materials, 2nd edn. (Wiley, New York, 1987)

Y. Takayama, J.A. Szpunar, H. Kato, Mater. Sci. Forum 495–497, 1049 (2009)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, Mater. Sci. Eng. 44, 1 (2004)

Satyanarayan, K.N. Prabhu, Adv. Colloid Interface Sci. 166, 87 (2011)

L. Zang, Z. Yuan, H. Xu, B. Xu, Appl. Surf. Sci. 257, 4877 (2011)

A. Wedi, D. Baither, G. Schmitz, Scr. Mater. 64, 689 (2011)

J. Yang, P. Shen, Z. Yin, J. Sun, Q. Jiang, Mater. Lett. 64, 2454 (2010)

Satyanarayan, K.N. Prabhu, in National Conference on Challenges in Research & Technology in the Coming Decades (CRT 2013) (Institution of Engineering and Technology, 2013), pp. 3.31–3.31

H. Okamoto, M.E. Schlesinger, E.M. Mueller, ASM Handbook Volume 3: Alloy Phase Diagrams (ASM International, 2016)

H.W. Lin, C.L. Lu, C.M. Liu, C. Chen, D. Chen, J.C. Kuo, K.N. Tu, Acta Mater. 61, 4910 (2013)

H. Chi Won, J.G. Lee, S. Katsuaki, M. Hirotaro, J. Electron. Mater. 32, 52 (2003)

N. Mookam, P. Tunthawiroon, K. Kanlayasiri, in IOP Conference Series: Materials Science and Engineering (2018)

S.R. A. Idris, N. Farihan, H. Kahar, in MATEC Web of Conferences, vol. 74 (2016), pp. 1–3

N. Mookam, K. Kanlayasiri, in MATEC Web of Conferences 192,(2018) ICEAST 2018 (2018), pp. 1–4

T. An, F. Qin, Microelectron. Reliab. 54, 932 (2014)

K.S. Kim, J.H. Kim, S.W. Han, Mater. Lett. 62, 1867 (2008)

Acknowledgments

The authors would like to express sincere gratitude to Faculty of Engineering of King Mongkut’s Institute of Technology Ladkrabang (KMITL) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mookam, N., Kanlayasiri, K. Effects of substrate annealing on wettability and intermetallic compound formation in Sn–3.0Cu/Cu systems. J Mater Sci: Mater Electron 30, 12087–12099 (2019). https://doi.org/10.1007/s10854-019-01566-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01566-9