Abstract

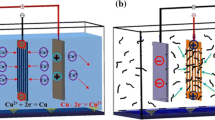

Directional assembly of anisotropic appearance filler in the composite is an effective way to obtain higher thermal conductivity thermal interface materials (TIMs). In this study, vertically aligned carbon fiber (VACF) scaffold reinforced polymer TIMs were fabricated using electrostatic flocking method, in which the aligned carbon fibers formed efficient heat conduction paths through the polymer matrix. By using high thermal conductivity mesophase pitch-based carbon fibers (mPCF) as filler, the maximum through plane thermal conductivity of the TIM with 13.4 wt% mPCF could reach up to 15.3 W/(m K), 60.2 times higher than that of the matrix, and the TIM also performed excellent flexibility. The influence of electrostatic flocking parameters on flocking effect was investigated. It is found that the electric field strength and the conductivity of fibers were the major factors to affect the vertical ratio of the mPCFs, and proper panels distance and fiber length were needed to acquire better flocking effect. In addition, the charging regular and the motion mechanism of fibers in electrostatic field were also discussed.

Similar content being viewed by others

References

A.L. Moore, L. Shi, Mater. Today 17(4), 163–174 (2014)

D.D.L. Chung, J. Mater. Eng. Perform. 10(1), 56–59 (2001)

R. Prasher, Proc. IEEE 94(8), 1571–1586 (2006)

X. Huang, P. Jiang, L. Xie, Appl. Phys. Lett. 95(24), 242901 (2009)

S. Yu, J.W. Lee, T.H. Han, ACS Appl. Mater. Interfaces 5(22), 11618–11622 (2013)

A. Saboori, M. Pavese, C. Badini, P. Fino, Acta Metall. Sin. 30(7), 675–687 (2017)

H.B. Cho, T. Nakayama, H. Suematsu, Compos. Sci. Technol. 129, 205–213 (2016)

H. Ding, Y. Guo, S.N. Leung, J. Appl. Polym. Sci. 133(4), 42910 (2016)

S.G. Mosanenzadeh, H.E. Naguib, Compos. Part B 85, 24–30 (2016)

S. He, J. Hu, C. Zhang, Polym. Test. 67, 295–301 (2018)

H. Yu, L. Li, T. Kido, J. Appl. Polym. Sci. 124(1), 669–677 (2012)

J.P. Cao, J. Zhao, X. Zhao, Compos. Sci. Technol. 89, 142–148 (2013)

Y. Xu, X. Li, H. Wang, J. Appl. Polym. Sci. 136(2), 46929 (2018)

Z.D. Han, A. Fina, Prog. Polym. Sci. 36(7), 914–944 (2011)

Q. Li, Y. Guo, W. Li, Chem. Mater. 26(15), 4459–4465 (2014)

A. Yu, P. Ramesh, X. Sun, E. Bekyarova, M.E. Itkis, R.C. Haddon, Adv. Mater. 20(24), 4740–4744 (2008)

X. Huang, C. Zhi, P. Jiang, J. Phys. Chem. C 116(44), 23812–23820 (2012)

Q. Liao, Z. Liu, W. Liu, C. Deng, N. Yang, Sci. Rep. 5, 16543 (2015)

W. Zhao, J. Kong, H. Liu, Nanoscale 8(48), 19984–19993 (2016)

Y.F. Zhang, D. Han, Y.H. Zhao, Carbon 109, 552–557 (2016)

Y.F. Zhang, Y.J. Ren, S.L. Bai, Int. J Heat. Mass Transf. 118, 510–517 (2018)

A.M. Marconnet, N. Yamamoto, M.A. Panzer, ACS Nano 5(6), 4818–4825 (2011)

H.B. Cho, A. Konno, T. Fujihara, Compos. Sci. Technol. 72(1), 112–118 (2011)

S. Wu, R.B. Lalani, J. Zhang, Carbon 94, 607–618 (2015)

B. Li, S. Dong, X. Wu, Compos. Sci. Technol. 147, 52–61 (2017)

K. Uetani, S. Ata, S. Tomonoh, T. Yamada, M. Yumura, K. Hata, Adv. Mater. 26(33), 5857–5862 (2014)

I. Dogu, Text. Res. J. 45(7), 521–532 (1975)

Y.K. Kim, Flocked Fabrics and Structures: Specialist Yarn and Fabric Structures, 1st edn. (Woodhead, Cambridge, 2011), pp. 287–317

G.B. Cho, J.S. Jeong, M.R. Chae, J.P. Noh, K.K. Cho, J.K. Kim, H.J. Ahn, T.H. Nam, K.W. Kim, Surf. Coat. Technol. 326, 443–449 (2016)

B. Tang, G. Hu, H. Gao, Int. J. Heat. Mass Transf. 85, 420–429 (2015)

Z. Lin, Y. Liu, ACS Appl. Mater. Interfaces 5(15), 7633–7640 (2013)

M.A. Raza, A.V.K. Westwood, A.P. Brown, C. Stirling, J. Mater. Sci.: Mater. Electron. 23(10), 1855–1863 (2012)

W.T. Hong, N.H. Tai, Diam. Relat. Mater. 18(7–10), 1571–1577 (2008)

Y. Hwang, M. Kim, J. Kim, Compos. Part A 55, 195–202 (2013)

H. Im, J. Kim, Carbon 50(15), 5429–5440 (2012)

S.H. Jeong, S. Chen, J. Huo, E.K. Gamstedt, J. Liu, S.L. Zhang, Z.B. Zhang, K. Hjort, Z. Wu, Sci. Rep. 5, 18257 (2015)

M.B. Jakubinek, M.A. White, M. Mu, Appl. Phys. Lett. 96(8), 083105 (2010)

J. Xu, A. Munari, E. Dalton, J. Appl. Phys. 106(12), 124310 (2009)

J. Hong, J. Lee, C.K. Hong, Curr. Appl. Phys. 10(1), 359–363 (2010)

M.A. Raza, A.V.K. Westwood, C. Stirling, Compos. Sci. Technol. 120, 9–16 (2015)

J. Hu, Y. Huang, X. Zeng, Compos. Sci. Technol. 160, 127–137 (2018)

Z. Yuan, J. Yu, Z. He, Fiber Polym. 15(12), 2581–2590 (2014)

S.H. Chung, H. Kim, S.W. Jeong, Carbon 140, 24–29 (2018)

C. Chen, H. Wang, T. Zhang, J. Mater. Sci. Technol. 35(1), 36–43 (2019)

Y.H. Bae, M.J. Yu, M.C. Vu, Compos. Sci. Technol. 155, 144–150 (2018)

K. Ahn, K. Kim, J. Kim, Ceram. Int. 41(8), 9488–9495 (2015)

Acknowledgements

We gratefully acknowledge the financial support from Ministry of Science and Technology of the People’s Republic of China (Grant No. 2013YQ120355).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, Z., Wei, S. & Guo, J. Fabrication of aligned carbon-fiber/polymer TIMs using electrostatic flocking method. J Mater Sci: Mater Electron 30, 10233–10243 (2019). https://doi.org/10.1007/s10854-019-01360-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01360-7