Abstract

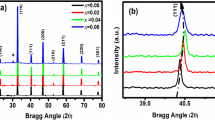

Ho2O3 doped Ba(Zr0.1Ti0.9)O3 ceramics were prepared by conventional solid state reaction route and their microstructure, dielectric properties and ferroelectric properties were investigated with the variation of Ho2O3 content using X-ray diffraction, scanning electron microscope, LCR measuring system and ferroelectric tester. It is found that the Ho3+ ions initially substitute the B-site host ions maintaining the perovskite structure in Ba(Zr0.1Ti0.9)O3 ceramics and then contribute to the formation of secondary phase with the continuous increase of Ho2O3 content. The average grain size decreases significantly as the Ho2O3 concentration increases. The ferroelectric-paraelectric phase transition temperature Tm of Ba(Zr0.1Ti0.9)O3 ceramics decreases with increasing Ho2O3 content. Based on the increase of critical exponent γ from the modified Curie–Weiss equation as well as the increase of deviation from Curie–Weiss law, the diffuse phase transition behavior is enhanced with increasing Ho2O3 content, indicating a composition-induced diffuse transition. A normal ferroelectric behavior with diffuse phase transition is obtained for the undoped Ba(Zr0.1Ti0.9)O3 ceramics. However, the relaxor-like ferroelectric behavior with a strong frequency dispersion of relative permittivity maximum εrmax at T < Tm and a strong diffuse phase transition is found for Ba(Zr0.1Ti0.9)O3 ceramics with high Ho2O3 content. The high Ho2O3 content ceramics obey the empirical Vogel–Fulcher relation, which confirms the relaxor behavior of Ba(Zr0.1Ti0.9)O3 ceramics with high Ho2O3 content. The remnant polarization increases and then decreases with the increasing Ho2O3 content while the coercive field decreases with the increase of Ho2O3 content in Ba(Zr0.1Ti0.9)O3 ceramics.

Similar content being viewed by others

References

G.N. Bhargavi, A. Khare, T. Badapanda, P.K. Ray, N. Brahme, Ceram. Int. 44, 1817 (2018)

C. Zhang, F. Chen, Z. Ling, G. Jian, Y. Li, Mater. Sci. Pol. 35, 806 (2018)

X. Chou, J. Zhai, H. Jiang, X. Yao, J. Appl. Phys. 102, 084106 (2007)

S.J. Kuang, X.G. Tang, L.Y. Li, Y.P. Jiang, Q.X. Liu, Scr. Mater. 61, 68 (2009)

U. Weber, G. Greuel, U. Boettger, S. Weber, D. Hennings, R. Waser, J. Am. Ceram. Soc. 84, 759 (2001)

D. Hennings, A. Schnell, G. Simon, J. Am. Ceram. Soc. 65, 539 (1982)

X.G. Tang, K.-H. Chew, H.L.W. Chan, Acta Mater. 52, 5177 (2004)

Y. Wang, L. Li, J. Qi, Z. Gui, Ceram. Int. 28, 657 (2002)

P.A. Jha, A.K. Jha, Ceram. Int. 40, 5209 (2014)

T. Badapanda, J. Adv. Ceram. 3, 339 (2014)

T. Badapanda, S.K. Rout, L.S. Cavalcante, J.C. Sczancoski, S. Panigrahi, T.P. Sinha, E. Longo, Mater. Chem. Phys. 121, 147 (2010)

X. Diez-Betriu, J.E. Garcia, C. Ostos, A.U. Boya, D.A. Ochoa, L. Mestres, R. Perez, Mater. Chem. Phys. 125, 493 (2011)

K.J. Park, C.H. Kim, Y.J. Yoon, S.M. Song, Y.T. Kim, K.H. Hur, J. Eur. Ceram. Soc. 29, 1735 (2009)

W. Cai, C. Fu, J. Gao, Z. Lin, X. Deng, Ceram. Int. 38, 3367 (2012)

C. Ciomaga, M. Viviani, M.T. Buscaglia, V. Buscaglia, L. Mitoseriu, A. Stancu, P. Nanni, J. Eur. Ceram. Soc. 27, 4061 (2007)

C. Zhang, Z. Ling, F. Chen, G. Jian, Y. Li, J. Mater. Sci.: Mater. Electron. 29, 331 (2018)

M.S. Alkathy, K.C. James Raju, J. Alloys Compd. 737, 464 (2018)

C. Zhang, F. Chen, Z. Ling, X. Zhong, G. Jian, Y. Li, J. Mater. Sci.: Mater. Electron. 29, 9397 (2018)

X.P. Jiang, M. Zeng, H.L.W. Chan, C.L. Choy, Mater. Sci. Eng. A 438–440, 198 (2006)

K.M. Sangwan, N. Ahlawat, R.S. Kundu, S. Rani, S. Rani, N. Ahlawat, S. Murugavel, J. Phys. Chem. Solids 117, 158 (2018)

W. Cai, C. Fu, Z. Lin, X. Deng, Ceram. Int. 37, 3643 (2011)

J. Chen, C. Fu, W. Cai, G. Chen, S. Ran, J. Alloys Compd. 544, 82 (2012)

H. Sun, Y. Zhang, X. Liu, Y. Liu, W. Chen, Ceram. Int. 41, 555 (2015)

J.W. Zhai, X. Yao, J. Shen, L.Y. Zhang, H. Chen, J. Phys. D 37, 748 (2004)

C. Zhang, Z. Ling, G. Jian, J. Mater. Sci.: Mater. Electron. 27, 11770 (2016)

Acknowledgements

This work is sponsored by Suzhou Pant Piezoelectric Tech. Co. Ltd and National Demonstration Center for Experimental Materials Science and Engineering Education (Jiangsu University of Science and Technology). This work is also funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Chen, F., Zhong, X. et al. Enhanced ferroelectric relaxor behavior of Ho2O3-modified barium zirconate titanate ceramics. J Mater Sci: Mater Electron 29, 16730–16739 (2018). https://doi.org/10.1007/s10854-018-9766-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9766-9