Abstract

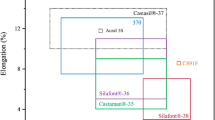

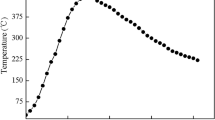

Transient liquid phase (TLP) bonding is a promising interconnection technology for high-temperature electronic packaging; however, the development is seriously limited by the long bonding time. Mixed powders with different melting points have been employed as interlayer to reduce the bonding time, but some problems still remain, such as void and undesirable property. In this paper, Cu–Cu substrates were bonded by using Sn–Ag mixed powders for a short time in air, and then the mechanism of void formation was studied, followed by a discussion of the effects of Ag/Sn proportion and powder size on the microstructures and mechanical properties of the joint. After bonded at 260 °C for just 10 min, the liquid Sn in solder paste is totally consumed, and the joint has a high shear strength of 39.5 MPa. The Ag/Sn proportion is vital to joint performance. Sn70Ag joint has the highest shear strength of 72.3 MPa, which is much more excellent than those in other studies due to the denser microstructures with fewer voids. The size of SnAgCu powders affects void size in the joint, and the size of Ag powders has a significant effect on the reaction process, suggesting that too large powders are not preferable. Moreover, the oxidation of small Sn powders should be given to sufficient attention. Finally, TLP bonding with mixed powders has an advantage over foil-based TLP bonding in terms of bonding efficiency and mechanical properties, as the bonding time is much shorter and the shear strength is much higher, which is related to the size and distribution of voids.

Similar content being viewed by others

References

Y.N. Zhou, Microjoining and Nanojoining, 1st edn. (CRC Press, New York, 2008)

H.A. Mantooth, M.M. Mojarradi, R.W. Johnson, IEEE Power Electron. Soc. Newslett. 18, 9 (2006)

R.W. Johnson, C. Wang, Y. Liu, J.D. Scofield, IEEE Trans. Electron. Packag. Manuf. 30, 182 (2007)

V.R. Manikam, K.Y. Cheong, IEEE Trans. Compon. Packag. Manuf. Technol. 1, 457 (2001)

V. Chidambaram, J.Hattel,J. Hald, Mater. Des. 31, 4638 (2010)

V. Chidambaram, J. Hattel, J. Hald, Microelectron. Eng. 88, 981 (2011)

J. Fan, C.S. Tan, Metall. 4, 71 (2012)

H. Alarifi, A. Hu, M. Yavuz, J. Electron. Mater. 40, 1394 (2011)

J.F. Yan, G.S. Zou, A.P. Wu, Scripta Mater. 66, 582 (2012)

W.Y. Sang, M.D. Glover, H.A. Mantooth, K. Shiozaki, J. Micromech. Microeng. 23, 15017 (2012)

E. Möller, A.A. Bajwa, E. Rastjagaev, J.Wilde, IEEE Electron. Compon. Technol. Conf. 64, 1707 (2014)

A.A. Bajwa, Y. Qin, R. Reiner, R. Quay, IEEE Electron. Compon. Technol. Conf. 64, 2181 (2014)

K. Guth, N. Oeschler, L. Boewer, R. Speckels, G. Strotmann, N. Heuck, S. Krasel, Integrat. Power Electron. Syst. 7, 1 (2012)

A. Sharif, M.N. Islam, Y.C. Chan, Mater. Sci. Eng. B 113, 184 (2004)

C.E. Ho, S.C. Yang, C.R. Kao, J. Mater. Sci. Mater. Electron. 18, 155 (2007)

N.S. Bosco, F.W. Zok, Acta Metall. 53, 2019 (2005)

M.S. Park, S.L. Gibbons, R. Arróyave, Microelectron. Reliab. 54, 1401 (2014)

H. Liu, K. Wang, K.E. Aasmundtveit, N. Hoivik, J. Electron. Mater. 41, 2453 (2012)

C. Hang, Y. Tian, R. Zhang, D.S. Yang, J. Mater. Sci. Mater. Electron. 24, 3905 (2013)

I. Panchenko, J. Grafe, M. Mueller, K.J. Wolter, IEEE Electron. Syst. Integrat. Technol. Conf. 4, 1 (2012)

G. Ross, H. Xu, V. Vuorinen, M. Paulasto-Krockel, IEEE Electron. Syst. Integrat. Technol. Conf. 5, 1 (2014)

K.E. Aasmundtveit, T.T. Luu, A.S.B. Vardoy, T.A. Tollefsen, IEEE Electron. Syst. Integrat. Technol. Conf. 5, 1 (2014)

K. Chu, Y. Sohn, C. Moon, Scripta Mater. 109, 113 (2015)

H.K. Shao, A.P. Wu, Y.D. Bao, Y. Zhao, G.S. Zou, J. Mater. Sci. Mater. Electron. 27, 4839 (2016)

J.J. Yu, C.A. Yang, Y.F. Lin, C.H. Hsueh, C.R. Kao, J. Alloys Compd. 629, 16 (2015)

R.A. Gagliano, M.E. Fine, J. Electron. Mater. 32, 1441 (2003)

J.F. Li, P.A. Agyakwa, C.M. Johnson, Acta Mater. 59, 1198 (2011)

H. Greve, L.Y. Chen, I. Fox, F.P. McCluskey, IEEE Electron. Compon. Technol. Conf. 63, 435 (2013)

H. Greve, S.A. Moeini, F.P. Mccluskey, IEEE Electron. Compon. Technol. Conf. 64, 1314 (2014)

X. Liu, S. He, H. Nishikawa, Scripta Mater. 110, 101 (2016)

X. Liu, S. He, H. Nishikawa, J. Alloys Compd. 695, 2165 (2016)

G. Ghosh, J. Mater. Res. 19, 1439 (2004)

P. Fima, Appl. Surf. Sci. 257, 3265 (2011)

A. Sharif, C.L. Gan, Z. Chen, J. Alloys Compd. 587, 365 (2014)

H.P.R. Frederikse, R.J. Fields, A. Feldman, J. Appl. Phys. 72, 2879 (1992)

H.K. Shao, A.P. Wu, Y.D. Bao, Y. Zhao, G.S. Zou, Mater. Sci. Eng. A 680, 221 (2017)

Acknowledgements

This research is financially supported by the National Science Foundation of China under Grant No. 51375260, which entitled “Technology and Mechanism of Low Temperature Transient Liquid Phase Bonding”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bao, Y., Wu, A., Shao, H. et al. Effect of powders on microstructures and mechanical properties for Sn–Ag transient liquid phase bonding in air. J Mater Sci: Mater Electron 29, 10246–10257 (2018). https://doi.org/10.1007/s10854-018-9076-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9076-2