Abstract

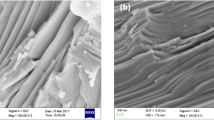

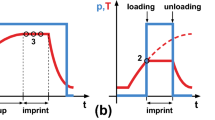

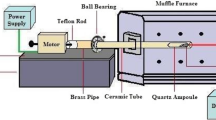

The influence of growth conditions on the morphology of stoichiometric indium monoselenide (InSe) crystals has been explored. Crystalline habits such as microfibres, needles, platelets and spherulites were obtained from physical vapour deposition by optimizing supersaturation, which sturdily depends on the temperature difference between charge (TC) and substrate (TS) zones ∆T, (= TC − TS). Morphology and growth mechanism were investigated with the aid of scanning electron microscopy and high-resolution transmission electron microscopy, which justified the layer by layer addition of atoms as per the Kossel–Stranski–Volmer model. Thermogravimetric measurements revealed the stability of InSe, confirming its melting point, M.P. = 611 °C, which reflects the formation of monophase. The mobility and carrier concentration calculated from the Hall effect experiment are found to be 11.14 cm2 V−1 s−1 and 1.52 × 1020 cm−3 respectively. Furthermore, optical characterizations such as UV–Vis–NIR and photoluminescence spectrometric analysis established the value of band gap as 1.45 eV, manifesting the versatility of the grown semiconducting platelets for photovoltaic applications.

Similar content being viewed by others

References

A. Li, P. Li, J. Hu, W. Zhang, J. Mater. Sci. Mater. Electron. 26, 5071 (2015)

C. Ye, X. Fang, Y. Hao, X. Teng, L. Zhang, J. Phys. Chem. B 109, 19758 (2005)

X. Fang, C. Ye, L. Zhang, Y. Wang, Y. Wu, Adv. Funct. Mater. 15, 63 (2005)

B. Celustka, S. Popovic, J. Appl. Crystallogr. 12, 416 (1979)

T. Ishii, J. Cryst. Growth 89, 459 (1988)

A. Chevy, J. Cryst. Growth 51, 157 (1981)

C. De Blasi, G. Micocci, S. Mongelli, A. Tepore, J. Cryst. Growth 57, 482 (1982)

A. Chevy, A. Kuhn, M.S. Martin, J. Cryst. Growth 38, 118 (1977)

A. Chevy, J. Cryst. Growth 67, 119 (1984)

C. De Blasi, G. Micocci, S. Mongelli, A. Tepore, F. Zuanni, Mater. Chem. Phys. 9, 55 (1983)

V.M. Katerynchuk, M.Z. Kovalyuk, M.V. Tovarnitskii, Semicond. Phys. Quantum Electron. Optoelectron. 9, 36 (2006)

B.R. Pamplin, Crystal Growth. (Pergamon, Hungary, 1975)

P.M. Reshmi, A.G. Kunjomana, K.A. Chandrasekharan, Cryst. Res. Technol. 46, 153 (2011)

G. Thankamma, A.G. Kunjomana, J. Cryst. Growth 415, 65 (2015)

M. Teena, A.G. Kunjomana, J. Appl. Cryst. 50, 1125 (2017)

G. Dhanaraj, K. Byrappa, V. Prasad, M. Dudley, Springer Handbook of Crystal Growth. (Springer, London, 2010)

A.G. Kunjomana, M. Teena, K.A. Chandrasekharan, J. Appl. Cryst. 47, 1841 (2014)

H.J. Scheel, P. Capper, Crystal Growth Technology from Fundamentals and Simulation to Large-scale Production. (Wiley, Weinheim, 2008)

B. Zhao, F. Wang, H. Chen, L. Zheng, L. Su, D. Zhao, X. Fang, Adv. Funct. Mater. 27, 1700264 (2017)

J. Wang, F. Cao, L. Jiang, Y. Guo, W. Hu, L. Wan, J. Am. Chem. Soc. 131, 15602 (2009)

J. Wu, Z. Hu, Z. Jin, S. Lei, H. Guo, K. Chatterjee, J. Zhang, Y. Yang, B. Li, Y. Liu, J. Lai, R. Vajtai, B. Yakobson, M. Tang, J. Lou, P.M. Ajayan, Adv. Mater. Interfaces, 3 (2016)

J. George, C.K. Valsalakumari, Cryst. Res. Technol. 21, 273 (1986)

H. Okamoto, J. Phase Equilib. Diffus. 25, 201 (2004)

J.B. Li, M.C. Record, J.C. Tedenac, Int. J. Mater. Res. 94, 381 (2003)

D.W. Boukhvalov, B. Gurbulak, S. Duman, L. Wang, A. Politano, L.S. Caputi, G. Chiarello, A. Cupolillo, Nanomaterials 7, 372 (2017)

B. Gurbulak, M. Sata, S. Dogan, S. Duman, A. Ashkhasi, E.F. Keskenler, Physica E 64, 106 (2014)

T. Ikari, S. Shigetomi, Phys. Status Solid. 124, K49 (1984)

J.L. Brebner, T. Steiner, M.L.W. Thewalt, Solid State Commun. 56, 929 (1985)

Acknowledgements

The authors are grateful to the Director, Sophisticated Test and Instrumentation Centre, Cochin University of Science and Technology, Kochi for the timely help to perform characterization of the samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teena, M., Kunjomana, A.G. Crystal shape engineering and studies on the performance of vapour deposited InSe platelets. J Mater Sci: Mater Electron 29, 5536–5547 (2018). https://doi.org/10.1007/s10854-018-8522-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-8522-5