Abstract

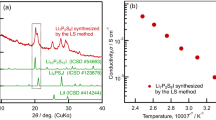

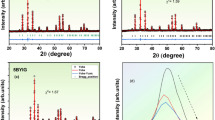

The Li2(Mg0.9A0.1)4TiO7 (A = Co2+, Ni2+, Mg2+, Zn2+, Ca2+) ceramics were prepared by the conventional solid-state reaction method. A series of Li2(Mg0.9A0.1)4TiO7 ceramics were investigated in regard to the sintering temperatures, crystal structures and dielectric properties. The Li2(Mg0.9A0.1)4TiO7 ceramic exhibited a single phase of Li2Mg4TiO7, and the Rietveld refinement was used to analyze the crystal structure. The Li2(Mg0.9Ca0.1)4TiO7 ceramics could be sintered below 1350 °C with high densities, high dielectric constants and near zero τf values. The maximum Q·f value of Li2(Mg0.9Zn0.1)4TiO7 was higher than that of Li2(Mg0.9A0.1)4TiO7 (A = Co2+, Ni2+, Mg2+, Ca2+). The optimum microwave dielectric properties of εr = 14.77, a high Q·f value of 162,200 GHz and τf = − 4.30 ppm/°C were achieved in Li2(Mg0.9Zn0.1)4TiO7 ceramic sintered at 1500 °C. In addition, Li2(Mg0.9Ca0.1)4TiO7 ceramic sintered at 1300 °C exhibited the suitable dielectric properties with a high εr value of 15.79, Q·f = 100,300 GHz and a near zero τf value of − 1.43 ppm/°C.

Similar content being viewed by others

References

M.T. Sebastian, H. Jantunen, Int. Mater. Rev. 53, 57 (2008)

T.A. Vanderah, Science 298, 1182 (2002)

I.M. Reaney, D. Iddles, J. Am. Ceram. Soc. 89, 2063 (2006)

C.H. Yang, Y.J. Han, X.S. Sun et al., Ceram. Int. 44, 6330 (2018)

G.G. Yao, X.S. Hu, X.L. Tian et al., Ceram. Int. 41, 563 (2015)

H.T. Wu, E.S. Kim, J. Alloys Compd. 669, 134 (2016)

G.G. Yao, P. Liu, H.W. Zhang, J. Mater. Sci.: Mater. Electron. 24, 1128 (2013)

Z.F. Fu, P. Liu, J.L. Ma et al., Mater. Lett. 164, 436 (2016)

Z.F. Fu, P. Liu, J.L. Ma et al., J. Eur. Ceram. Soc. 36, 625 (2016)

J.X. Bi, C.C. Li, Y.H. Zhang et al., Mater. Lett. 196, 128 (2017)

Y.M. Lai, X.L. Tang, X. Huang et al., J. Eur. Ceram. Soc. 38, 1508 (2018)

C.H. Su, F.C. Lin, T.M. Chu et al., J. Alloys Compd. 686, 608 (2016)

P. Zhang, K.K. Sun, L. Liu et al., J. Alloys Compd. 765, 1209 (2018)

J.X. Bi, C.F. Xing, Y.H. Zhang et al., J. Alloys Compd. 727, 123 (2017)

Z.X. Fang, B. Tang, F. Si et al., Ceram. Int. 43, 1682 (2017)

H.T. Chen, B. Tang, X. Guo et al., J. Mater. Sci.: Mater. Electron. 46, 1230 (2017)

B.W. Hakki, P.D. Coleman, IRE Trans. Microw. Theory Tech. 8, 402 (1960)

W.E. Courtney, IEEE Trans. Microw. Theory Technol. 18, 476 (1970)

M. Tabuchi, K. Ado, H. Kobayashi et al., J. Solid State Chem. 141, 5541 (1998)

J. Li, Y. Han, T. Qiu et al., Mater. Res. Bull. 47, 2375 (2012)

R.D. Shannon, Am. Miner. 77, 94 (1992)

R.D. Shannon, J. Appl. Phys. 73, 348 (1993)

W.S. Kim, E.S. Kim, K.H. Yoon, J. Am. Ceram. Soc. 82, 2111 (1999)

Acknowledgements

This work was supported by China Postdoctoral Science Foundation (2017M612341). The authors are thankful to the help of Professor Zhenxing Yue and postdoctoral Jie Zhang on the measurement of microwave properties in Tsinghua University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, C.F., Liu, Q.Q. & Wu, H.T. Sintering characteristics, crystal structure, and microwave dielectric properties of Li2(Mg0.9A0.1)4TiO7 (A = Co2+, Ni2+, Mg2+, Zn2+, Ca2+). J Mater Sci: Mater Electron 30, 302–307 (2019). https://doi.org/10.1007/s10854-018-0293-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0293-5