Abstract

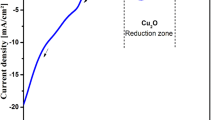

In present investigation, we have successfully synthesized nanocrystalline Cu2S thin films at different deposition time via single step hydrothermal route. The synthesized Cu2S thin films characterized for their optostructural, morphological, compositional and photoelecrochemical properties as function of deposition time. Thickness of deposited Cu2S thin films increases with increase in deposition time. The optical studies revealed that band gap of Cu2S thin films decrease with increase in deposition time. Structural study confirm that Cu2S thin films are nanocrystalline in nature with pure hexagonal crystal structure. Crystallite size were increases with increase in deposition time. Raman spectrum shows the presence of sharp band at 472 cm−1 confirms the formation of pure phase hexagonal Cu2S thin film. Scanning electron microscopy micrographs of Cu2S thin films demonstrate that significant change in surface morphology. The high resolution transmission electron microscopy and selected area emission diffraction study indicate that nanocrystalline Cu2S thin films formation. X-ray photoelectron spectroscopy and energy dispersive X-ray spectroscopy show the presence of elements and preferred valence state with stoichiometric composition of the Cu2S thin films. electron impedance spectroscopy reveals that charge transfer resistance (Rct) decreases with increase in deposition time. From J–V measurements, it was found that, Cu2S thin films shows maximum conversion efficiency is 0.27% for film after deposition of 6 h.

Similar content being viewed by others

References

A.P. Alivisatos, Science 271, 933–937 (1996)

W.U. Huynh, J.J. Dittmer, A.P. Alivisatos, Science 295, 2425–2427 (2002)

H.H. Kung, M.C. Kung, Catal. Today 97, 219–224 (2004)

I. Grozdavon, J. Solid State Chem. 114, 469–475 (1995)

S. Wang, S. Yang, Chem. Mater. 13, 4794–4799 (2001)

M.C. Brelle, C.L. Torres, J.C. Mcnulty, R.K. Mehra, J.Z. Zhang, Pure Appl. Chem. 72, 101–117 (2013)

W. Liang, M.H. Whangbo, Solid State Commun. 85, 405–408 (1993)

8T.Z. Gang, Z.Q. An, G.X. Zhi, Z.J. Fu, W.W. Yong, L.A. Ping, J. Alloys Compd. 695, 1778–1785 (2017)

J.S. Cruz, S.A.M. Hernandez, F.P. Delgado, O.Z. Angel, R.C. Perez, G.T. Delgado, Int. J. Photoenergy 2013,178017 (2013)

J.S. Chung, S.J. Sohn, J. Power Sources 108, 226–231 (2002)

A.A. Sagade, R. Sharma, Sens. Actuators B 133, 135–143 (2008)

M.V. Haritha, Y.S. Lee, M. Gopi, H.J. Kim, RSC Adv. 6, 45809–45818 (2016)

M. Xin, K.W. Li, H. Wang, Appl. Surf. Sci. 256, 1436–1442 (2009)

X.L. Liu, Y.J. Zhu, Mater. Lett. 65, 1089–1091 (2011)

T.Y. Ding, M.S. Wang, S.P. Guo, G.C. Guo, J.S. Huang, Mater. Lett. 62, 4529–4531 (2008)

P. Roy, S.K. Srivasta, Mater. Lett. 61, 1693–1697 (2007)

Z. Yao, X. Zhu, C. Wu, X. Zhang, Y. Xie, Cryst. Growth Des. 7, 1256–1261 (2007)

Z.H. Yang, D.P. Zhang, W.X. Zhang, M. Chen, J. Phys. Chem. Solids 70, 840–846 (2009)

X.L. Yu, H.L.W. Chan, Y. Wang, C.B. Cao, Microporous Mesoporous Mater. 118, 423–426 (2009)

J. Vedel, P. Cowache, M. Soubeyrand, Sol. Energy Mater. 10, 25–34 (1994)

H.S.S. Ranjel, A.C. Castillo, J.F.H. Paz, J.R.F. Mancilla, H.C. Montes, P.E.G. Casillas, C.A.M. Perez, C.A.R. Gonzalez, Chalcogenide Lett. 12, 381–387 (2015)

D. Selle, J. Maege, Phys. Status Solidi. 30, 153–155 (1968)

C. Gautier, G. Breton, M. Nouaoura, M. Cambon, S. Charar, M. Averous, Thin Solid Films 315, 118–122 (1998)

L. Reijnen, B. Meester, F.d. Lange, J. Schoonman, A. Goossens, Chem. Mater. 17, 2724–2728 (2005)

F.A. Sabah, N.M. Ahmed, Z. Hassan, H.S. Rasheed, J. Sci. Res. Dev. 13, 95–99 (2015)

B. Bharathi, S. Thanikaikarasan, P. Kollu, P.V. Chandrasekar, K. Sankaranarayanan, X.S. Shajan, J. Mater. Sci. Mater. Electron. 25, 5338–5344 (2014)

J. Podder, R. Kobayashi, M. Ichimura, Thin Solid Films 472, 71–75 (2005)

A.D. Dhondge, S.R. Gosavi, N.M. Gosavi, C.P. Sawant, A.M. Patil, A.R. Shelke, N.G. Deshpande, World J. Condens. Matter Phys. 5, 1–9 (2015)

D. Li, J. Ma, L. Zhou, Y. Li, C. Zo, Optik Int. J. Light Electron Opt. 126, 4971–4973 (2015)

F. Hao, P. Dong, Q. Luo, J. Li, J. Lou, H. Lin, Energy Environ. Sci. 6, 2003 (2013)

S. Siol, H. Strater, R. Bruggemann, J. Brotz, G. Bauer, A. Klein, W. Jargermann, J. Phys. D 46, 495112 (2013)

S.A. Phaltane, S.A. Vanalakar., T.S. Bhat, P.S. Patil, S.D. Sartale. L.D. Kadam, J. Mater. Sci. Mater. Electron. 28, 8186–8191 (2017)

S.A. Vanalakar, G.L. Agwane, M.G. Gang, P.S. Patil, J.H. Kim, J.Y. Kim, Phys. Status Solidi C 12, 500–503 (2015)

S.A. Vanalakar, P.S. Patil, J.H. Kim, Sol. Energy Mater. Sol. Cells 182, 204–219 (2018)

S.H. Pawar, P.N. Bhosale, Mater. Chem. Phys. 11, 461–479 (1994)

W. Ostwald, L. der, Allg. Chem. 2, 1 (1896)

R.M. Mane, S.R. Mane, R.R. Kharade, P.N. Bhosale, J. Alloys Compd. 491, 321–324 (2010)

B.D. Ajalkar, R.K. Mane, B.D. Sarwade, P.N. Bhosale, Sol. Energy Mater. Sol. Cells 81, 101–112 (2004)

K.V. Khot, S.S. Mali, N.B. Pawar, R.R. Kharade, R.M. Mane, V.V. Kondalkar, P.B. Patil, P.S. Patil, C.K. Hong, J.H. Kim, J. Heo, P.N. Bhosale, New J. Chem. 38, 5964–5974 (2014)

M.M. Salunkhe, K.V. Khot, P.S. Patil, T.M. Bhave, P.N. Bhosale, New J. Chem. 39, 3405–3416 (2015)

J. Pelleg, E. Elish, Vac. Surf. Films 20, 754–761 (2002)

R. Herberholz, M.J. Carter, Sol. Energy Mater. Sol. Cells. 44, 357–366 (1996)

X. Shuai, W. Shen, Z. Hou, S. Ke, C. Xu, C. Jiang, Nanoscale Res. Lett. 9, 513 (2014)

C.S. Bagade, S.S. Mali, V.B. Ghanwat, K.V. Khot, P.B. Patil, S.D. Kharade, R.M. Mane, N.D. Desai, C.K. Hong, P.S. Patil, P.N. Bhosale, RSC Adv. 5, 55658–55668 (2015)

X. Meng, M. Sun, Y. Hu, M. Yin, Z.L. Yu, N. Yu, H. Li, T. Shu, J. Alloys Compd. 735, 2142–2147 (2017)

S.K. Jagadale, K.V. Khot, C.S. Bagade, R.M. Mane, V.B. Ghanwat, R.K. Mane, S.S. Mali, C.K. Hong, P.N. Bhosale, J. Mater. Sci. Mater. Electron. 28, 2984–2995 (2017)

S. Poulston, P.M. Parlett, P. Stone, M. Bowker, Surf. Interface Anal. 24, 811–820 (1996)

S.A. Vanalakar, S.S. Mali, R.C. Pawar, N.L. Tarwal, A.V. Moholkar, A. Jin, J.H. Kim, P.S. Patil, J.A. Kim, Y. Kwon. Electrochim. Acta 56, 2762–2768 (2011)

S.A. Vanalkar, P.S. Patil, Chemical synthesis of Cds, Zno and Cds sensitized Zno thin films and their characterization for photo-electrochemical solar cells (Shivaji University, Kolhapur, 2010). http://handle.net/10603/4064

G. Hodes, Nature 285, 29–30 (1980)

M. Ali, P. Ramirez, S. Mafe, R. Neumann, W. Ensinger, ACS Nano 3, 603–608 (2009)

S.S. Mali, B.M. Patil, C.A. Betty, P.N. Bhosale, Y.W. Ohd, S.R. Jadkar, R.S. Devanf, Y. Ron Maf, P.S. Patil, Electrochim. Acta 66, 216–221 (2012)

A.D. Savariraj, K.K. Viswanathan, K. Prabakar, Electrochim. Acta 149, 364–369 (2014)

V.V. Kondalkar, S.S. Mali, R.R. Kharade, K.V. Khot, P.B. Patil, R.M. Mane, S. Choudhury, P.S. Patil, C.K. Hong, J.H. Kim, P.N. Bhosale, Dalton Trans. 44, 2788–2800 (2015)

Acknowledgements

One of the author, SSP is very much thankful to Department of Science and Technology (DST), New Delhi for providing DST-INSPIRE fellowship for financial support (Registration No. IF160712). This work is also supported by Basic science and research programme through the National Science Research Foundation of Korea (NRF) funded by Ministry of Education (NRF = 2009–0094055).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patil, S.S., Bagade, C.S., Joshi, M.P. et al. Facile hydrothermal assisted synthesis of time dependent Cu2S thin films for efficient photoelectrochemical application. J Mater Sci: Mater Electron 29, 19322–19335 (2018). https://doi.org/10.1007/s10854-018-0059-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0059-0