Abstract

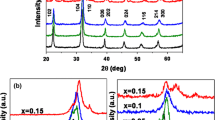

Polycrystalline BiFe0.25Cr0.75O3 thin films have been fabricated via a chemical deposition technique at various thicknesses (60-, 130-, 190-, 240 nm). The effect of Cr substitution on BiFeO3 structures have been briefly discussed by performing X-ray diffraction and SAED pattern. The nature of the films surface at different thicknesses were briefly discussed using scanning electron microscope and transmission electron microscope. Roughness and other amplitude parameters of the film at different thickness are studied through atomic force microscopy. The result indicates that, when changing the thickness of the film, the average bond length gets changed causing difference in electrical and magnetic properties. Electrical and dielectric study reveals thickness dependent property and is deeply understood from space charge, oxygen vacancies and super-exchange interaction. Film at 60 nm shows higher magnetization with 8.5042 emu/cm3 and with a retentivity of 3.852 emu/cm3 than the thick film. Further, the spin-cooling behavior and magnetization below room temperature from 2 to 300 K were analyzed briefly for spintronics applications.

Similar content being viewed by others

References

B. Issa, I.M. Obaidat, B.A. Albiss, Y. Haik, Int. J. Mol. Sci. 14, 21266 (2013)

L. Landau, E. Lifshits, Ukr. J. Phys 53, 14 (2008)

I.E. Dzyaloshinskii, Sov. Phys. JETP 37, 628 (1960)

K. Oka, M. Azuma, W. Chen, H. Yusa, A.A. Belik, E.T. Muromachi, M. Mizumaki, N. Ishimatsu, N. Hiraoka, M. Tsujimoto, M.G. Tucker, J. Paul Attfield, Y. Shimakawa, J. Am. Chem. Soc. 132, 9438 (2010)

D. Chen, S. Hsu, A.K. Yadav, J.D. Clarkson, RSC Adv. 7, 42088 (2017)

W. Li Yin, X. Mi, Wang, Sci. Rep. 6, 20591 (2016)

H. Yang, Z. Jin, H. Hu, G. Lu, Y. Bi, RSC Adv. 7, 10774 (2017)

D. Wang, A. Khesro, S. Murakami, A. Feteira, Q. Zhao, I.M. Reaney, J. Eur. Ceram. Soc. 37, 1857 (2017)

K.F. Wang, J.M. Liuand, Z.F. Ren, Adv. Phys. 58, 321 (2009)

Y. Wang, T. Gould, J.F. Dobson, H. Zhang, H. Yang, X. Yao, H. Zhao, Phys. Chem. Chem. Phys. 16, 1424 (2014)

R.V. William, A. Marikani, D. Madhavan, Ferroelect. Lett. Sec. 44, 14 (2017)

J. Chen, X. Xing, A. Watson, W. Wang, R. Yu, J. Deng, L. Yan, C. Sun, X. Chen, Chem. Mater. 19, 3598 (2007)

L.S. Devia, K.N. Devi, B.I. Sharma, H.N. Sarma, J. Appl. Phys. 6, 6 (2014)

D. Raoufi, F. Hosseinpanahi, J. Theor. Appl. Phys. 21, 1 (2013)

A.A. Saif, N. Ramli, P. Poopalan, Jordan J. Phys. 3, 61 (2010)

B. Rajesh Kumar, T. Subba Rao, Digest J. Nanomater. Biostruct. 7, 1881 (2012)

R.V. William, A. Marikani, D. Madhavan, Ceram. Int. 42, 6807 (2016)

S.K. Singh, K. Maruyama, H. Ishiwara, Integr. Ferroelect. 97, 83–89 (2008)

S.K. Chang, Y.J. Kim, J. Korean Phys. Soc. 65, 1063 (2014)

K. Abe, N. Sakai, J. Takahashi, H. Itoh, N. Adachi, T. Ota, Jpn. J. Appl. Phys. 49, 09MB01 (2010)

S.H. Jo, S.G. Lee, S.H. Lee, Mater. Res. Bull. 47, 409 (2012)

Z. Zhong, S.K. Singh, Y. Sugiyama, H. Ishiwara, Jpn. J. Appl. Phys. 48, 101402 (2009)

J. Wu, J. Wang, D. Xiao, J. Zhu, ACS Appl. Mater. Interfaces 3, 3261 (2011)

H.K. Kim, F.G. Shi, IEEE Trans. Dielectr. Electr. Insul. 8, 2 (2001)

H.C. Li, Appl. Phys. Lett. 73, 464 (1998)

K. Prashanthi, S.P. Duttagupa, R. Pinto, V.R. Palkar, IEEE Explores 978, 1728 (2007)

J. Wu, J. Wang, J. Appl. Phys. 106, 054115 (2009)

J. Wang, J.B. Neaton, H. Zheng, V. Nagarajan, S.B. Ogale, B. Liu, D. Viehland, V. Vaithyanathan, D.G. Schlom, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, M. Wuttig, R. Ramesh, Science 299, 1719 (2003)

C.D. Cao, R. Klingeler, H. Vinzelberg, N. Leps, W. Löser, G. Behr, F. Muranyi, V. Kataev, B. Büchner, Phys. Rev. B 82, 134446 (2010)

N.M. Murari, R. Thomas, A. Winterman, R.E. Melgarejo, S.P. Pavunny, R.S. Katiyara, J. Appl. Phys. 105, 084110 (2009)

Acknowledgements

The work was fully supported by DST-SERB project, India. Authors are thankful to IIT-SAIF, Chennai and UGC-DAE Indore, India for their constant support in instrumentation facilities. SSA acknowledges DST, BRNS, CEFIPRA, DRDO and UGC (SAP), New Delhi. Authors also wish to acknowledge the management and Principal of Mepco Engineering College, Sivakasi for their encouragement and support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

William, R.V., Sivaprakash, P., Marikani, A. et al. Surface modification and enhanced multiferroic behavior of BiFe0.25Cr0.75O3 films with different thickness over Pt(111)/Ti/SiO2/Si substrate. J Mater Sci: Mater Electron 29, 4457–4465 (2018). https://doi.org/10.1007/s10854-017-8393-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8393-1