Abstract

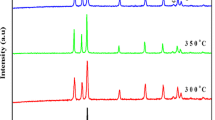

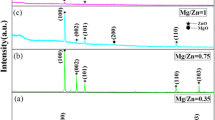

ZnO nanorods have been prepared by hydrothermal method and the reaction temperatures are 120, 140, 160 and 180 °C, respectively. Microstructure, morphology, chemical composition and optical properties of the samples were investigated in detail. XRD and Raman spectrum analysis shows that the best crystal performance of ZnO obtained at 140 °C. The samples are mainly composed of morphology nanorods and abundant ZnO nanorods with hexagon-shaped crystallites structure are emerged at all reaction temperatures. XPS measurement indicates that the Zn and O surface atom ratio is estimated about 1.13:1 for the sample prepared at 140 °C. Compared with the UV–Visible absorption spectra of the samples obtained at 120, 140 and 180 °C, absorption edge appears slight blue shift phenomenon with reaction temperature increasing and the absorption intensity reduces at the same time. These analyses reveal that the optical band gap increases with increasing of reaction temperature and all the gaps are less than the standard value 3.2 eV of ZnO.

Similar content being viewed by others

References

F. Meng, N. Hou, S. Ge, B. Sun, Z. Jin, W. Shen, L. Kong, Z. Guo, Y. Sun, H. Wu, C. Wang, M. Li, J. Alloy. Compd. 626, 124–130 (2015)

M. Kocakuşakoğlu, M. Dağlar, H.C. Konyar, K. Yatmaz, Öztürk, J. Eur. Ceram. Soc. 35, 2845–2853 (2015)

R. Aladpoosh, M. Montazer, Carbohyd. Polym. 126, 122–129 (2015)

R.M. Bashami, A. Hameed, M. Aslam, I.M.I. Iqbal, M.T. Soomro, Anal. Methods 7, 1794–1801 (2015)

S. Lam, J. Sin, A.R. Mohamed, Mater. Lett. 167, 141–144 (2016)

S. Kundu, S. Sain, M. Yoshio, T. Kar, N. Gunawardhana, S.K. Pradhan, Appl. Surf. Sci. 329, 206–211 (2015)

Y. Zhang, J. Luo, Scripta Mater. 106, 26–29 (2015)

Y. Zhang, J. Jung, J. Luo, Acta Mater. 94, 87–100 (2015)

L. Kong, X. Yin, M. Han, L. Zhang, L. Cheng, Ceram. Int. 41, 4906–4915 (2015)

S.D. Senol, O. Ozturk, C. Terzioğlu, Ceram. Int. 41, 11194–11201 (2015)

M. Kahouli, A. Barhoumi, Anis Bouzid, A. Al-Hajry, S. Guermazi, Superlattice Microst. 85, 7–23 (2015)

D. Escobedo-Morales, M.L.R. Téllez-Flores, J. Peralta, A.M. Garcia-Serrano, E. Herrera-González, E. Rubio-Rosas, O.O. Sánchez-Morad, Xometl, Mater. Chem. Phys. 151, 282–287 (2015)

Y. Wang, J. Yang, Y. Li, T. Jiang, J. Chen, J. Wang, Mater. Chem. Phys. 153, 266–273 (2015)

S. Luo, Y. Shen, Z. Wu, M. Cao, F. Gu, L. Wang, Mater. Sci. Semicon. Proc. 41, 535–543 (2016)

A. Kathalingam, H.C. Park, S.D. Kim, H.S. Kim, S. Velumani, T. Mahalingam, J. Mater. Sci. Mater. Electron. 26, 5724–5734 (2015)

G. He, X. Chen, Z. Sun, Surf. Sci. Rep. 68, 68–107 (2013)

J. Liu, W. Cao, H. Jin, J. Yuan, D. Zhang, M. Cao, J. Mater. Chem. C 3, 4670–4677 (2015)

Y. Qing, C. Yang, C. Hu, Y. Zheng, C. Liu, Appl. Surf. Sci. 326, 48–54 (2015)

C.T. Dominguez, M.A. Gomes, Z.S. Macedo, C.B. Araújo, A.S.L. Gomes, Nanoscale 7, 317–323 (2015)

S. Chang, P. Yang, C. Lai, S. Lu, G. Li, W. Chang, H. Tuan, CrystEngComm 18, 616–621 (2016)

G. He, J. Gao, H. Chen, J. Cui, Z. Sun, X. Chen, ACS Appl. Mater. Interfaces 6, 22013–22025 (2014)

K. Ocakoglu, S.A. Mansour, S. Yildirimcan, A.A. Al-Ghamdi, F. El-Tantawy, F. Yakuphanoglu, Spectrochim. Acta A 148, 362–368 (2015)

J. Podporska-Carroll, A. Myles, B. Quilty, D.E. McCormack, R. Fagan, S.J. Hinder, D.D. Dionysioue, S.C. Pillai, J. Hazard. Mater. 324, 39–47 (2017)

I.M. El-Nahhal, J.K. Salem, S. Kuhn, T. Hammad, R. Hempelmann, S.A. Bhaisi, Powder Technol. 287, 439–446 (2016)

N. Tu, K.T. Nguyen, D.Q. Trung, N.T. Tuan, V. Nam, P.T. Do, Huy, J. Lumin. 174, 6–10 (2016)

X. Li, S. Feng, S. Liu, Z. Li, L. Wang, Z. Zhan, W. Lu, RSC Adv. 6, 96479–96483 (2016)

R. Chauhan, M. Shinde, A. Kumar, S. Gosavi, D.P. Amalnerkar, Microporous Mesoporous Mater. 226, 201–208 (2016)

D.V. Dao, M. Bremt, Z. Koeller, T.K. Le, Powder Technol. 288, 366–370 (2016)

S. Jafarirad, M. Mehrabi, B. Divband, M. Kosari-Nasab, Mater. Sci. Eng. C 59, 296–302 (2016)

V.D. Mote, Y. Purushotham, B.N. Dole, Mater. Design 96, 99–105 (2016)

J. Kennedy, P.P. Murmu, E. Manikandan, S.Y. Lee, J. Alloys Compd. 616, 614–617 (2014)

R. Al-Gaashani, S. Radiman, A.R. Daud, N. Tabet, Y. Al-Douri, Ceram. Int. 39, 2283–2292 (2013)

M. Gromyko, T. Krunks, A. Dedova, D. Katerski, I.O. Klauson, Acik, Appl. Surf. Sci. 405, 521–528 (2017)

F. Cocco, B. Elsener, M. Fantauzzi, D. Atzei, A. Rossi, RSC Adv. 6, 31277–31289 (2016)

N.S.A. Zak, A.M. Aziz, F. Hashim, Kordi, Ceram. Int. 42, 13605–13611 (2016)

V.E. Podasca, T. Buruiana, E.C. Buruiana, Appl. Surf. Sci. 377, 262–273 (2016)

H. Wang, G. Yi, X. Zu, P. Qin, M. Tan, H. Luo, Mater. Lett. 162, 83–86 (2016)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Nos. 51772003 and 51472003), Anhui Provincial Natural Science Foundation (1608085ME95 and 1708085MF149), the Anhui University Provincial Natural Science Research Project, China (KJ2016A524 and KJ2016B07), the Higher Education Excellent Youth Talents Foundation of Anhui Province (gxyqZD2016328, gxyqZD2016329), and the Research Project of Chuzhou University (2015qd04). The authors would like to thank Zhongqing Lin of the Experimental Technology Center of Anhui University, for electron microscope test and discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, X., Zheng, S., Lin, Q. et al. Structural and optical properties of ZnO nanorods: influence of reaction temperature. J Mater Sci: Mater Electron 29, 1933–1938 (2018). https://doi.org/10.1007/s10854-017-8103-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8103-z