Abstract

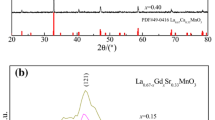

A systematic investigation of structure, electrical and magnetic properties of polycrystalline ceramics La0.67Ca0.33−x K x MnO3 (x = 0.05, 0.10, 0.15, 0.20, 0.25) samples, prepared by sol–gel method had been undertaken. As K content increases the crystal structures were transformed from orthorhombic to rhombohedral structure identified by X-ray diffraction, and the effect of increasing K ion is to increment the Mn–O–Mn bond angle. The surface morphology was investigated by scanning electron microscope, which indicates that grain size decreasing with increasing of K+. Temperature dependence of resistivity (ρ − T) was measured by standard four-probe method. The insulator–metal transition temperature (T P ) shifted to higher temperature and the temperature coefficient of resistivity decreased sharply with the substitution K+ for Ca2+ ion. The temperature dependence of magnetization (M–T) shown that Curie temperature (T C ) was increasing with the increase of K content, which can be explained by enhancement of double–exchange interaction. The data of resistivity on low-temperature (T < T P ) had been fitted with the relation ρ(T) = ρ 0 + ρ 2T2 + ρ 4.5T4.5; the high-temperature (T > T P ) resistivity data were explained using small-polaron hopping and variable-range hopping models. Resistivity data in whole temperature range (100–320 K) could be fitted by percolation model. Polaron activation energy E a was found to decrease with the content K+ increasing, which suggested that K doping increase bond angle Mn–O–Mn, thereby the effective band gap was decreased and the double exchange coupling was increased of, this is the reason for the decrease of resistivity.

Similar content being viewed by others

References

A. Dhahri, F.I.H. Rhouma, S. Mnefgui, J. Dhahri, K.E. Hlil, Ceram. Int. 40, 459 (2014)

A. Selmi, R. M’Nassri, W. Cheikhrouhou-Koubaa, N.C. Boudjada, A. Cheikhrouhou, Ceram. Int. 41, 10177 (2015)

S. Mnefgui, N. Zaidi, N. Dhahri, J. Dhahri, E.K. Hlil, J. Magn. Magn. Mater. 384, 219 (2015)

M.H. Ehsani, P. Kameli, S.F. Razavi, M.E. Ghazi, B. Aslibeiki, J. Alloys Comp. 579, 406 (2013)

A.G. Gamzatov, A.B. Batdalov, L.N. Khanov, A.S. Mankevich, I.E. Korsakov, A.R. Kaul, Phys. Solid State 54, 617 (2012)

C. Zener, Phys. Rev. 82, 403 (1951)

D. Neila, D. Abdessalem, D. Jemai, H.E. Kebir, D. Essebti, J. Magn. Magn. Mater. 326, 129 (2013)

D.G. Kuberkar, R.R. Doshia, P.S. Solankia, U. Khachara, M. Vagadiaa, A. Ravaliaa, V. Ganesanb, Appl. Surf. Sci. 258, 9041 (2012)

A.J. Millis, P.B. Littlewood, B.I. Shraiman, Phys. Rev. Lett. 74, 5144 (1995)

X. Yin, X. Liu, Y. Yan, Q. Chen, J. Sol-Gel. Sci. Technol. 70, 361 (2014)

M. Ben Rejeba, C. Ben osmanb, Y. Regaiega, A. Marzouki-Ajmia, W. Cheikhrouhou-Koubaa, S. Ammar-Merah, A. Cheikhrouhou, T. Mhiri, J. Alloys Compd. 695, 2597 (2017)

A.M. Showkat, Y.P. Zhang, S. Kim, A.I. Gopalan, K.R. Reddy, K.P. Lee, Bull. Korean Chem. Soc. 28, 1985 (2007)

M. Jeem, L. Zhang, J. Ishioka, T. Shibayama, T. Iwasaki, T. Kato, S. Watanabe, Nano Lett. 17, 3 (2017)

R.K. Raghava, S.B. Cheol, C.H. Yoo, P. Wonjung, R.K. Sun, L.J. Shin, S. Daewon, L. Youngil, Scripta Mater. 58, 1010 (2008)

R.K. Raghava, K.P. Lee, A.I. Gopalan, J. Nanosci. Nanotechnol. 7, 3117 (2007)

R.K. Raghava, K. Nakata, T. Ochiai, T. Murakami, D.A. Tryk, A. Fujishima, J. Nanosci. Nanotechnol. 11, 3692 (2011)

R.K. Raghava, V.G. Gomes, M. Hassan, Mater. Res. Expr. 1, 015012 (2014)

C. Murat, K.R. Reddy, A.M. Fernando, Chem. Eng. J. 309, 151 (2017)

M. Hassan, E. Haque, K.R. Reddy, A.I. Minett, J. Chen, G.V. Gomes, Nanoscale 6, 11988 (2014)

R.K. Raghava, K.P. Lee, A.I. Gopalan, Colloids Surf. A 320, 49 (2008)

F. Jin, H. Zhang, X. Chen, X. Liu, Q. Chen, J. Sol-Gel Sci. Technol. 81, 177 (2017)

J. Ma, Y. Cai, W. Wang, Q. Cui, M. Theingi, H. Zhang, Ceram. Int. 40, 4963 (2014)

M. Eshraghi, P. Kameli, F. Khalili, M.H. Ehsani, H. Salamati, J. Rare Earths 32, 965 (2014)

S. Das, T.K. Dey, Solid State Commun. 134, 837 (2005)

C. Boudaya, L. Laroussi, E. Dhahri, J.C. Joubert, A. Cheikhrouhou, J. Phys. Condens. Mat. 10, 7485 (1998)

G.H. Rao, J.R. Sun, K. Bärner, N. Hamad, J. Phys. Condens. Mat. 11, 1523 (1999)

F.C. Fonseca, J.A. Souza, R.F. Jardim, R. Muccillo, E.N.S. Muccillo, D. Gouvea, M.H. Jung, A.H. Lacerda, J. Eur. Ceram. Soc. 24, 1271 (2004)

X. Xu, J. Bullock, L.T. Schelhas, E.Z. Stutz, J.J. Fonseca, M. Hettick, V.L. Pool, K.F. Tai, M.F. Toney, X. Fang, A. Javey, L.H. Wong, J.W. Ager, Nano Lett. 16, 1925 (2016)

R.K. Raghava, L.K. Pill, L. Youngil, G.A. Iyengar, Mater. Lett. 62, 1815 (2008)

R.K. Raghava, S.B. Cheol, R.K. Sun, N. Jaegeun, L. Youngil, Synth. Met. 159, 1934 (2009)

K.L. Yanapu, S.S. Samatham, D. Kumar, V. Ganesan, P.V. Reddy, Appl. Phys. A 122, 1 (2016)

S. Hcini, S. Khadhraoui, S. Zemni, A. Triki, H. Rahmouni, M. Boudard, M. Oumezzine, J. Supercond. Novel Magn. 26, 2181 (2013)

S.P. Schiffer, A.P. Ramirez W. Bao, S.W. Cheong, Phys. Rev. Lett. 75, 3336 (1995)

E.S. Vlakhov, R.A. Chakalov, R.I. Chakalova, K.A. Nenkov, K. Dorr, A. Handstein, K.H. Muller, J. Appl. Phys. 83, 2152 (1998)

H. Ahmed, S. Khan, W. Khan, R. Nongjai, I. Khan, J. Alloys Compd. 563, 12 (2013)

T. Holstein, Ann. Phys. 8, 343 (1959)

Y.K. Lakshmi, P.V. Reddy, J. Alloys Compd. 470, 67 (2009)

D. Varshney, N. Dodiya, J. Theor. Appl. Phys. 9, 45 (2014)

S.A. Ahmed, J. Magn. Magn. Mater. 340, 131 (2013)

T. Nakajima, Y. Ueda, J. Alloys Compd. 383, 135 (2014)

S.O. Manjunatha, A. Rao, V.P.S. Awana, G.S. Okram, J. Magn. Magn. Mater. 394, 130 (2015)

S.O. Manjunatha, A. Rao, T.Y. Lin, C.M. Chang, Y.K. Kuo, J. Alloys Compd. 619, 303 (2015)

S. Bhattacharya, S. Pal, R.K. Mukherjee, B.K. Chaudhuri, S. Neeleshwar, Y.Y. Chen, S. Mollah, H.D. Yang, J. Magn. Magn. Mater. 269, 359 (2004)

S.T. Yazdi, P. Iranmanesh, J. Magn. Magn. Mater. 365, 100 (2014)

T.D. Thanh, L.H. Nguyen, D.H. Manh, N.V. Chien, P.T. Phong, N.V. Khiem, L.V. Hong, N.X. Phuc, Phys. B 407, 145 (2012)

F. Yonglai, Appl. Phys. Lett. 77, 118 (2000)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Number 11564021).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, D., Chen, Q., Li, Z. et al. Structure, electrical and magnetic properties of La0.67Ca0.33−x K x MnO3 polycrystalline ceramic. J Mater Sci: Mater Electron 29, 1808–1816 (2018). https://doi.org/10.1007/s10854-017-8089-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8089-6