Abstract

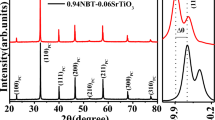

Ba4(Ce0.5Sm0.5)9.3Ti18−z Al z O54 (BCSTA, z = 0, 0.25, 0.50, 0.75, 1.00) ceramics sintered in nitrogen atmosphere were prepared by the conventional solid state reaction. The effects of Al3+ substitution for Ti4+ on microstructure and microwave dielectric properties in BCSTA ceramics have been investigated. X-ray diffraction spectra revealed only a single tungsten bronze in all the samples from z = 0 to z = 1.00 and backscatter electronic images confirmed a second BaAl2Ti5O14 phase at z > 0.50. Besides, XPS results indicated that the incorporation of Al3+ suppressed the reduction of Ti4+, which leaded to the microwave dielectric properties such as Q × f and τ f value improvement in BCSTA ceramics. Typically, the optimum combination of microwave dielectric properties: Q × f ∼ 8401.76 GHz, ε r ∼ 71.68, and τ f ∼ +4.37 ppm/°C were obtained at z = 0.50 in BCSTA ceramics sintered in nitrogen atmosphere.

Similar content being viewed by others

References

R.J. Cava, J. Mater. Chem. 11, 54 (2001)

H. Ohsato, M. Mizuta, T. Okuda, J. Ceram. Soc. Jpn. 106, 178 (1998)

S.Y. Wu, Y. Li, X.M. Chen, J. Phys. Chem. Solids 64, 2365 (2003)

H. Ohsato, J. Eur. Ceram. Soc. 21, 2703 (2001)

H. Kishi, Y. Mizuno, H. Chazono, Jpn. J. Appl. Phys. 42, 1 (2003)

J.X. Gao, X.H. Wang, M.J. Wang, and et al, J. Mater. Sci. 27, 5954 (2016)

R.C. Pullar, S.J. Penn, J. Eur. Ceram. Soc. 29, 419 (2009)

X.G. Yao, H.X. Lin, W. Chen, and et al, Ceram. Int. 38, 3011 (2012)

Y. Ota, K.I. Kakimoto, H. Ohsato, and et al, J. Eur. Ceram. Soc. 24, 1755 (2004)

B. Tang, Z. Xiong, H. Li, and et al, J. Mater. Sci. 26, 8017 (2015)

M.C. Wu, M.K. Hsieh, C.W. Yen, and et al, J. Eur. Ceram. Soc. 27, 2835 (2007)

J. Tao, M.L. Mu, X.H. Wang et al., J. Mater. Sci. 1–7 (2017)

H. Ohsato, T. Ohhashi, S. Nishigaki et al., Jpn. J. Appl. Phys. 32, 4323 (1993)

R. Ubic, I.M. Reaney, W.E. Lee et al., Mat. Res. Soc. Symp. Proc. 453, 495 (1997)

K.H. Yoon, W.S. Kim, E.S. Kim, Mater. Sci. Eng. 99, 112 (2003)

X. Wang, J.H. Luo, H. Guan, and et al, J. Mater. Sci. 28, 10338 (2017)

M. Mizuta, K. Uenoyama, H. Ohsato et al., Jpn. J. Appl. Phys. 35, 5065 (1996)

Z. Xiong, B. Tang, Z.X. Fang et al., J. Alloys Compd. 723, 580 (2017)

A. Templeton, X.R. Wang, S.J. Penn et al., J. Am. Ceram. Soc. 83, 95 (2000)

H.T. Chen, B. Tang, A.Q. Cao, and et al, J. Mater. Sci. 26, 405 (2015)

Z.X. Fang, B. Tang, F. Si et al., J. Alloys Compd. 693, 843 (2017)

B.W. Hakki, P.D. Coleman, Ire. Trans. Micro. Theory Technpl. 8, 402 (1960)

W.D. Cai, F. Chen, X.X. Shen, and et al, Appl. Catal. B 101, 160 (2010)

R.D. Shannon, Acta. Cryst 32, 751 (1976)

X.G. Yao, H.X. Lin, X.Y. Zhao et al., Ceram. Int. 38, 6723 (2012)

H. Borchert, Y.V. Frolova, V.V. Kaichev et al., J. Phys. Chem. B 109, 5728 (2005)

X.G. Yao, W. Chen, L. Luo, Adv. Mater. Chem. 2, 28 (2012)

X.M. Chen, Y. Li, J. Am. Ceram. Soc. 85, 579 (2002)

H. Takahashi, Y. Baba, K. Ezaki et al., Jpn. J. Appl. Phys. 30, 2339 (1991)

P.K. Davies, J. Tong, T. Negas, J. Am. Ceram. Soc. 80, 1727 (1997)

P.J. Harrop, J. Mater. Sci. 4, 370 (1969)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51302093). The authors are grateful to the Analytical and Testing Center, Huazhong University of Science and Technology, for the XPS analyses. And the authors appreciate the State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, Wuhan University of Technology, for the field-emission scanning electron microscope examination.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, J., Mu, M., Wang, X. et al. Improved microwave dielectric properties of anti-reduction Ba4(Ce0.5Sm0.5)9.3Ti18−zAlzO54 ceramics sintered in nitrogen atmosphere. J Mater Sci: Mater Electron 29, 1392–1398 (2018). https://doi.org/10.1007/s10854-017-8046-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8046-4