Abstract

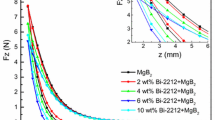

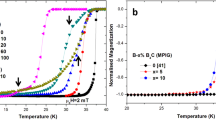

Bulk MgB2 samples with 2 wt% urea have been prepared by melting impregnation method at 800 °C. Based on the advantage of MgO dissolution from urea, the size of MgO particles was significantly reduced (~10 nm) by the melting impregnation method to realize more efficient pinning effect than conventional urea doping. As the content of such MgO pinning centers inevitably decreased to be less than 2.3 vol%, the critical current density of the melting impregnated sample was enhanced (5.0 × 103 A cm−2, 20 K and 3 T) over the entire field, in contrast with the un-doped sample. This is on the other hand attributed to the C substitution for B and nano-sized amorphous regions within the MgB2 grains, which brought extra pinning effects. Instead of dissolving the edge of the MgB2 grains, the dispersed urea by impregnation method mainly corroded the interior of the MgB2 grains to introduce such amorphous defects for excellent superconducting properties.

Similar content being viewed by others

References

J. Nagamatsu, N. Nakagawa, T. Muranaka, Y. Zentani, J. Akimitsu, Nature 410, 63–64 (2001)

D.K. Finnemore, J.E. Ostenson, S.L. Bud’ko, G. Lapertot, P.C. Canfield, Phys. Rev. Lett. 86, 2420–2422 (2001)

M.A. Susner, S.D. Bohnenstiehl, S.A. Dregia, M.D. Sumption, Y. Yang, J.J. Donovan, E.W. Collings, Appl. Phys. Lett. 104, 162603 (2014)

J.H. Kim, S. Oh, Y.-U. Heo, S. Hata, H. Kumakura, A. Matsumoto, M. Mitsuhara, S. Choi, Y. Shimada, M. Maeda, J.L. MacManus-Driscoll, S.X. Dou, NPG Asia Mater. 4, e3–e7 (2012)

X. Xu, J.H. Kim, W.K. Yeoh, Y. Zhang, S.X. Dou, Supercond. Sci. Technol. 19, L47–L50 (2006)

P. Kovac, I. Husek, T. Melisek, L. Kopera, M. Kulich, Supercond. Sci. Technol. 10, 10LT01 (2016)

O. Erdem, E. Yanmaz, J. Mater. Sci. 27, 6502–6510 (2016)

K. Berger, M.R. Koblischka, B. Douine, J. Noudem, P. Bernstein, T. Hauet, J. Leveque, IEEE Trans. Appl. Supercond. 26, 6801005 (2016)

J. Karpinski, N.D. Zhigadlo, S. Katrych, R. Puzniak, K. Rogacki, R. Gonnelli, Phys. C 456, 3–13 (2007)

S.X. Dou, S. Soltanian, J. Horvat, X.L. Wang, S.H. Zhou, M. Ionescu, H.K. Liu, P. Munroe, M. Tomsic, Appl. Phys. Lett. 81, 3419–3421 (2002)

A. Yamamoto, J. Shimoyama, S. Ueda, I. Iwayama, S. Horii, K. Kishio, Supercond. Sci. Technol. 18, 1323–1328 (2005)

H. Fujii, K. Ozawa, H. Kitaguchi, Supercond. Sci. Technol. 27, 035002 (2014)

F. Qin, Q. Cai, H. Chen, J. Alloy. Compd. 633, 201–206 (2015)

P.M. Schaber, J. Colson, S. Higgins, D. Thielen, B. Anspach, J. Brauer, Thermochim. Acta 424 (2004) 131–142.

S.H. Zhou, A.V. Pan, D. Wexler, S.X. Dou, Adv. Mater. 19, 1373–1376 (2007)

Q. Cai, Y. Liu, Z. Ma, L. Yu, Scr. Mater. 67, 92–95 (2012)

C.P. Bean, Phys. Rev. Lett. 8, 250–253 (1962)

H.M. Rietveld, J. Appl. Crystallogr. 2, 65–71 (1969)

M. Avdeev, J.D. Jorgensen, R.A. Ribeiro, S.L. Budko, P.C. Canfield, Phys. C 387, 301–306 (2003)

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Grant No. 51402213) for grant and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, F., Cai, Q., Liu, Y. et al. Removal of MgO and enhancement of critical current density in urea-doped MgB2 bulks by melting impregnation method. J Mater Sci: Mater Electron 28, 15625–15629 (2017). https://doi.org/10.1007/s10854-017-7450-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7450-0