Abstract

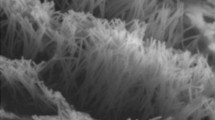

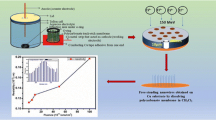

Copper nanowires of diameter 80 nm were synthesized in polycarbonate membrane using template technique. Samples were then implanted with 160 keV O−1 ion beam with varying particle fluence of 1 × 1012, 5 × 1012 and 1 × 1013 ions/cm2. The SRIM (Stopping and range of ions in matter) software was used to study the processes involved. Compositional analysis confirms implantation of oxygen ions and the stoichiometry of Cu:O was found to be 6:1 by weight % when implanted at 1 × 1013 ions/cm2. Scanning electron microscopy reveals no changes in morphology of nanowires on implantation. X-ray diffraction analysis showed no shifting in the ‘2θ’ position of diffraction peaks however some new diffraction peaks of oxygen were seen. Implantation with oxygen ion led to the increased crystallite size and reduced strain. The conductivity of the nanowires was found to increase linearly with the ion fluence presenting constructive effect of negative ion implantation on copper nanowires.

Similar content being viewed by others

References

J. Weber, R. Singhal, S. Zekri, A. Kumar, Int. Mater. Rev. (2013)

L. Hu, G. Chen, Nano Lett. 7, 11 (2007)

E.C. Walter, M.P. Zach, F. Favier, B. J. Murray, K. Inazu, J.C. Hemminger, R.M. Penner, Chem. Phys. Chem. 4, 2 (2003)

C. Yong, B.C. Zhang, C.S. Seet, A. See, L. Chan, J. Sudijono, S.L. Liew, C.H. Tung, H.C. Zeng, J. Phys. Chem. B 106, 48 (2002)

H. Choi, S.H. Park, J. Am. Chem. Soc. 126, 20 (2004)

S. Kumar, V. Kumar, S.K. Sharma, S. K. Sharma, S.K. Chakarvarti, Superlattice. Microst. 48(1), 66–71 (2010)

C.F. Monson, A.T. Woolley, Nano Lett. 3, 3 (2003)

Z. Liu, Y. Yang, J. Liang, Z. Hu, S. Li, S. Peng, Y. Qian, J. Phys. Chem. B 107, 46 (2003)

J.G. Zhao, Z. H. Hua, Y. Yao, Superlattice. Microst. 61 (2013)

I. Lisiecki, A. Filankembo, H.S.- Kongehl, K. Weiss, M.-P. Pileni, J. Urban, Phys. Rev. B 61, 7 (2000)

Q. Li, C. Wang, Chem. Phys. Lett. 375, 5 (2003)

X. Chen, H. Duan, Z. Zhou, J. Liang, J. Gnanaraj, Nanotechnology 19, 36 (2008)

S. Kumar, D. Saini, G.S. Lotey, N. K. Verma Superlattice. Microst. 50(6) (2011) 698–702.

J.W. Mayer, O. Marsh, lon Implantation in Semiconductors, Academic Press, New York, 1970

F.A. Smidt, Int. Mater. Rev. (2013)

P. Rana, R. P. Chauhan, J. Mater. Sci.-Mater. Electron 25, 12 (2014).

J. Ishikawa, Surf. Coat. Tech. 65, 1–3 (1994)

J. Ishikawa, H. Tsuji, M. Mimura, S. Ikemura, Y. Gotoh, Surf. Coat. Tech. 103 (1998)

J. Ishikawa, H. Tsuji, Y. Toyota, Y. Gotoh, K. Matsuda, M. Tanjyo, S. Sakai, Nucl. Instrum. Meth. B 96, 1 (1995)

H. Tsuji, N. Arai, N. Gotoh, T. Minotani, T. Ishibashi, T. Okumine, K. Adachi, H. Kotaki, Y. Gotoh, J. Ishikawa, Surf. Coat. Tech. 201, 19 (2007)

H. Tsuji, N. Sakai, H. Sugahara, Y. Gotoh, J. Ishikawa, Nucl. Instrum. Meth. B 237, 1 (2005)

C. Narula, R.P. Chauhan, J. Alloy Compd. 684, 261–270 (2016)

C. Narula, R. P Chauhan, J. Mater. Sci.-Mater. Electron 28, (2017)

A. Huczko Appl. Phys. A 70, 4 (2000)

G. Cao, D. Liu, Adv. Colloid. Interface 136, 1 (2008)

J.F. Ziegler, J.P. Biersack, The stopping and range of ions in matter, In Treatise on Heavy-Ion Science, pp. 93–129. Springer Newyork (1985)

J.F. Ziegler, J.P. Biersack, U. Littmark (2008). SRIM 2008.04:http://www.SRIM.org.

N. Kishimoto, V.T. Gritsyna, Y. Takeda, C.G. Lee, T. Saito, Nucl. Instrum. Meth. B 141, 1 (1998)

G.K. Williamson, W. H. Hall, Acta. Metall. Mater. 1, 1 (1953)

A.A. Nazarov, A. E. Romanov, R. Z. Valiev, Nanostruct. Mater. 4, 1 (1994)

W. Qin, J.A. Szpunar, Phil. Mag. Lett. 85, 12 (2005)

N. Kumar, R. Kumar, S. Kumar, S. K. Chakarvarti, J. Mater. Sci. Mater. Electron 25, 8 (2014)

P.D. Kanungo, R. Kogler, K.N. Duc, N. Zakharov, P. Werner, U. Gosele, Nanotechnology 20, 16 (2009)

R.P. Chauhan, P. Rana, J. Radioanal. Nucl. Chem. 302, 2 (2014)

J. Ishikawa, H. Tsuji, Y. Gotoh, Surf. Coat. Tech. 203, 17 (2009)

Acknowledgements

One of the authors (Anita Rani) is thankful to UGC, New Delhi, for providing financial support in terms of project. The authors wish to acknowledge the Director, IUAC, New Delhi, for providing Low Energy Ion Beam Facility. Authors also acknowledge NIT Kurukshetra, India for SEM and XRD facilities and SAI Lab, Thapar University, Patiala, India for providing EDS facility.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Rana, P., Narula, C., Rani, A. et al. Ion implantation effects of negative oxygen on copper nanowires. J Mater Sci: Mater Electron 28, 9998–10006 (2017). https://doi.org/10.1007/s10854-017-6757-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6757-1