Abstract

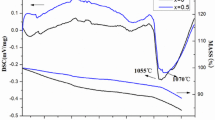

The ZnxFe2.5-xNi2Mn1.5O8(0 ≤ x ≤ 0.8) ceramics with different compositions were synthesized by co-precipitation method. The effects of Zn doping on the structure, electrical properties and stability of the ceramic samples were characterized by X-ray diffraction (XRD), scanning electron microscope (SEM), electrical measurement and X-ray photoelectron spectroscopy (XPS) analysis. It was found that, as the Zn doping content in the ZnxFe2.5-xNi2Mn1.5O8 samples increased, both the grain size and the density decreased. The XPS analysis confirmed the conduction of as-sintered ceramic structure was mainly due to hopping of electrons between Mn3+/Mn4+ and Fe2+/Fe3+ ions. The values of B 25/50 constant, ρ 25 and E a of ZnxFe2.5-xNi2Mn1.5O8 ceramic samples were in the range of 5375–4177 K, 9042–18 KΩ•cm and 0.464–0.360 eV, respectively. The values of relative resistance drift (ΔR/R 0 ) were in the range of 0.58–2.78% and had a minimum value with the Zn content of x = 0.2 after aging test at 125 °C for 500 h. This suggests that the electrical properties of ZnxFe2.5-xNi2Mn1.5O8 ceramic system can be adjusted to desired values by controlling the Zn ion doping content. Besides, the stability of Mn-Ni-Fe-O ceramic can be effectively improved by Zn doping.

Similar content being viewed by others

References

C.J. Ma, Y.F. Liu, Y.N. Lu, J. Mater. Sci. Mater. Electron. 26, 7238 (2015).

A. Feteira, J. Am. Ceram. Soc. 92, 967 (2009).

K. Park, D.Y. Bang, J. Mater. Sci. Mater. Electron. 14, 81 (2003)

L. Chen, W.W. Kong, J.C. Yao, J. Mater. Sci. Mater. Electron. 27, 1713 (2016)

J. Takahashi, A. Miura, H. Itoh, Ceram. Int. 34, 853 (2008)

F. Chen, J.H. Wang, H.M. Zhang, J. Mater. Sci. Mater. Electron. 26, 1374 (2015)

D. Theyvaraju, S. Muthukumaran, M. Ashokkumar, J. Mater. Sci. Mater. Electron. 24, 5189 (2013)

W.A. Groen, C. Metzmacher, V. Zaspalis, J. Eur. Ceram. Soc. 21, 1793 (2001)

Z.B. Wang, C.H. Zhao, P.H. Yang, J. Eur. Ceram. Soc. 2833, 26 (2006)

J.Y. Wang, J.J. Zhang, Mater. Sci. Eng. B. 176, 616 (2011)

R.K Sharma, R. Ghose, Ceram. Int. 41, 14684 (2015).

S.G. Wang, A.M. Chang, H.M. Zhang, Mater. Chem. Phys. 110, 83 (2008)

H.M. Zhang, A.M. Chang, C.W. Peng. Microelectron. Eng. 88, 2934 (2011)

S.G. Fritsch, C. Chanel, J. Sarrias, Solid. State. Ion. 128, 233 (2000)

A.R. Bueno, M.L. Gregori, M.C.S. Nóbrega, Mater, Chem. Phys. 105, 229 (2007)

C. Zhao, Y. Zhao, J. Mater. Sci: Mater. Electron. 23, 1788 (2012)

K. Park, J.K. Lee, Scripta. Mater. 57, 329 (2007).

D.A. Zatsepin, D.W. Boukhvalo, N.V. Gavrilov, Appl. Surf. Sci. 387, 1093 (2016)

M. P. Michalska, A. Kowalczyk, G. Chełkowska, J. Alloy. Compd. 385, 44 (2004)

A. Kania, S. Miga, E. Talik, J. Eur. Ceram. Soc. 36, 3369 (2016)

H.M. Liu, G.L. Wei, Z. Xu, Appl. Surf. Sci. 389, 438 (2016)

L.Y. Deng, F.T. Lin, Q.Q. Yu, J. Mater. Sci. 51, 7491 (2016)

E.S. Ilton, J.E. Post, P.J. Heaney, Appl. Surf. Sci. 366, 475 (2016)

A.K. Singh, A. K. Singh, T.C. Goelb. J. Magn, Magn. Mater. 281, 276 (2004)

Acknowledgements

Autonomous Region Youth Science and technology innovation personnel training project (No. QN2015JQ010).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xie, X., Chen, M., Liu, T. et al. Effects of Zn-doping on the electrical properties of ZnxFe2.5−xNi2Mn1.5O8 (0≤ x ≤ 0.8) NTC ceramics by co-precipitation method. J Mater Sci: Mater Electron 28, 8655–8661 (2017). https://doi.org/10.1007/s10854-017-6589-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6589-z