Abstract

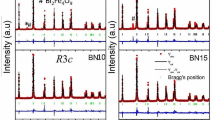

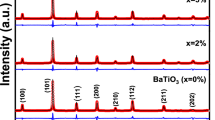

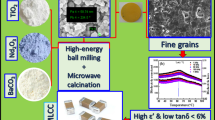

Ti4+ substituted (Bi0.9Ba0.1)(Fe1−yTiy)O3 ceramics (0.0 ≤ y ≤ 0.15) were synthesized by auto combustion method. Rietveld refinement reveals a transformation from rhombohedral to tetragonal with the Ti4+ doping content at y = 0.05. Effect of Ti4+ doping on the dielectric properties of Ba2+ doped BiFeO3 was studied from room temperature to 400 °C in wide range of frequency. Initially, the dielectric loss was found to increase in ceramics with low Ti4+ content and then after decreases with further increase in Ti4+ concentration. The electrical conductivity of Bi0.9Ba0.1Fe1−yTiyO3 ceramics obeys the Arrhenius law, revealing the controlled conduction mechanism of oxygen vacancies at the higher range of temperature. The highest d 33 value of 15.8 pC/N was exhibited by the composition with Ti4+ doping at y = 0.05. Ti4+ doped BBFO ceramics showed similar behavior of weak ferromagnetism as Bi0.9Ba0.1FeO3. Also, magnetization was found to increase with Ti4+ doping content up to 0.05 and then decreases with further increase in doping concentration.

Similar content being viewed by others

References

W. Eerenstein, N.D. Mathur, J.F. Scott, Nature 442, 759–765 (2006). doi:10.1038/nature05023

W. Prellier, M.P. Singh, P. Murugavel, J. Phys.: Condens. Matter 17, 803–832 (2005). doi:10.1088/0953-8984/17/30/R01

R. Ramesh, N.A. Spaldin, Nat. Mater. 6, 21–29 (2007). doi:10.1038/nmat1805

A. Singh, V. Pandey, R.K. Kotnala, D. Pandey, Phys. Rev. Lett. 101, 247602 (2008). doi:10.1103/PhysRevLett.101.247602

Y.L. Han, W.F. Liu, P. Wu, X.L. Xu, M.C. Guo, G.H. Rao, S.Y. Wang, J. Alloys Compd. 661, 115–121 (2015). doi:10.1016/j.jallcom.2015.11.157

G. Catalan, J.F. Scott, Adv. Mater. 2, 2463–2485 (2009). doi:10.1002/adma.200802849

C. Nayek, A. Tamilselvan, C. Thirmal, P. Murugavel, S. Balakumar, J. Appl. Phys. 115, 073902 (2014). doi:10.1063/1.4865958

K.C. Verma, R.K. Kotnala, RSC Adv. 6, 57727 (2016). doi:10.1039/C6RA12949H

M.A. Basith, O. Kurni, M.S. Alam, B.L. Sinha, B. Ahmmad, J. Appl. Phys. 115, 024102 (2014). doi:10.1063/1.4861151

M. Kumar, K.L. Yadav, J. Appl. Phys. 100, 074111 (2006). doi:10.1063/1.2349491

Y.H. Gu, Y. Wang, F. Chen, H.L.W. Chan, W.P. Chen, J. Appl. Phys. 108, 094112 (2010). doi:10.1063/1.3506526

P. Kumar, C. Panda, M. Kar, Smart Mater. Struct. 24, 045028 (2015). doi:10.1088/0964-1726/24/4/045028

G.F. Cheng, Y.J. Ruan, W. Liu, X.S. Wu, Phys. B 468, 81–84 (2015). doi:10.1016/j.physb.2015.04.023

H. Deng, M. Zhang, Z. Hu, Q. Xie, Q. Zhong, J. Wei, H. Yan, J. Alloys Compd. 582, 273–276 (2014). doi:10.1016/j.jallcom.2013.07.187

R.D. Shannon, Acta Crystallogr. A 32, 751–767 (1976)

P. Debye, Ann. Phys. 351, 809–823 (1915). doi:10.1002/andp.19153510606

H. Singh, K.L. Yadav, J. Phys.: Condens. Matter 23, 385901 (2011). doi:10.1088/0953-8984/23/38/385901

H. Singh, K.L. Yadav, Mater. Chem. Phys. 132, 17–21 (2012). doi:10.1016/j.matchemphys.2011.08.058

L. Benguigui, Solid State Commun. 11, 825–828 (1972). doi:10.1016/0038-1098(72)90280-3

P.K. Patel, K.L. Yadav, H. Singh, A.K. Yadav, J. Alloy Comp. 591, 224–229 (2014). doi:10.1016/j.jallcom.2013.12.119

A.K. Behera, N.K. Mohanty, B. Behera, P. Nayak, Adv. Mat. Lett. 4, 141–145 (2013). doi:10.5185/amlett.2012.6359

H. Singh, A. Kumar, K.L. Yadav, Mat. Sci. Eng. B 176, 540–547 (2011). doi:10.1016/j.mseb.2011.01.010

M. Kumar, S. Shankar, O. Parkash, O.P. Thakur, J. Mater. Sci.: Mater. Electron. 25, 888–896 (2014). doi:10.1007/s10854-013-1661-9

Z. Dai, Y. Akishige, J. Phys. D Appl. Phys. 43, 445403 (2010). doi:10.1088/0022-3727/43/44/445403

J. Wang, B. Neaton, H. Zheng, V. Nagarajan, S.B. Ogale, B. Liu, D. Viehland, V. Vaithyanathan, D.G. Schlom, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, M. Wuttig, R. Ramesh, Science 299, 1719–1722 (2003). doi:10.1126/science.1080615

C.W. Bark, S. Ryu, Y.M. Koo, H.M. Jang, H.S. Youn, Appl. Phys. Lett. 90, 022902 (2007). doi:10.1063/1.2430678

V.V. Shvartsman, W. Kleemann, R. Haumont, J. Kreisel, Appl. Phys. Lett. 90, 172115 (2007). doi:10.1063/1.2731312

T.J. Park, G.C. Papaefthymiou, A.J. Viescas, A.R. Moodenbaugh, S.S. Wong, Nano Lett. 7, 766–772 (2007). doi:10.1021/nl063039w

R. Mazumder, P.S. Devi, D. Bhattacharya, P. Choudhury, A. Sen, M. Raja, Appl. Phys. Lett. 91, 062510 (2007). doi:10.1063/1.2768201

B. Bhushan, Z. Wang, J.V. Tol, N.S. Dalal, A. Basumallick, N.Y. Vasanthacharya, S. Kumar, D. Das, J. Am. Ceram. Soc. 95, 1985–1992 (2012). doi:10.1111/j.1551-2916.2012.05132.x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaur, M., Uniyal, P. Investigation on the effect of Ti doping on dielectric, impedance and magnetic properties of Ba2+-substituted BiFeO3 ceramics. J Mater Sci: Mater Electron 27, 12539–12549 (2016). https://doi.org/10.1007/s10854-016-5789-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5789-2