Abstract

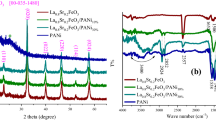

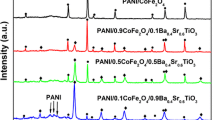

In this paper, La0.8K0.2MnO3 powder was synthesized by sol–gel method. The phase structure, morphology of the composite have been characterized by X-ray diffraction, field emission scanning electron microscope. Testing of the microwave absorption was carried out by using the network analyzer Agilent HP-8722ES at room temperature. The results show that the La0.8K0.2MnO3 powder has excellent absorbing property. The maximum reflection loss is −33.51 dB at about 12.22 GHz with a thickness of only 1.25 mm. Moreover, the bandwidth with the reflection loss above 10 dB reaches about 2.1 GHz.

Similar content being viewed by others

References

D. Sun, Q. Zou, Y. Wang, Y. Wang, W. Jiang, F. Li, Nanoscale 6, 6557–6562 (2014)

S.H. Hosseini, A. Asadnia, M. Moloudi, Mater. Res. Innov. 19, 107–112 (2015)

Y. Qing, W. Zhou, F. Luo, D. Zhu, J. Magn. Magn. Mater. 321, 25–28 (2009)

J.H.M. Gan, Q.Q. Ni, T. Natsuki, J. Alloys Compd. 615, 84–90 (2014)

Z. Xie, D. Geng, X. Liu, S. Ma, Z. Zhang, J. Mater. Sci. Technol. 27, 607–614 (2011)

X. Liu, X. Cui, Y. Chen, X.J. Zhang, R. Yu, G.S. Wang, H. Ma, Carbon 95, 870–878 (2015)

D. Zhang, F. Xu, J. Lin et al., Carbon 80, 103–111 (2014)

G. Li, G.G. Hu, H.D. Zhou, X.J. Fan, X.G. Li, Mater. Chem. Phys. 75, 101–104 (2002)

T. Nakajima, Y. Ueda, J. Alloys Compd. 383, 135–139 (2004)

Y.S. Nam, H.L. Ju, C.W. Park, Solid State Commun. 119, 613–618 (2001)

W. Chen, J. Zheng, Y. Li, J. Alloys Compd. 513, 420–424 (2012)

X.F. Zhang, X.L. Dong, H. Huang, B. Lv, J.P. Lei, C.J. Choi, J. Phys. D Appl. Phys. 40, 5383–5387 (2007)

S. Zhang, Q. Cao, M. Zhang, X. Shi, J. Appl. Phys. 113, 074903 (2013)

S.Y. Zhang, Q.X. Cao, Mater. Sci. Eng. B 177, 678–684 (2012)

C.Y. Tsay, R.B. Yang, D.S. Hung, Y.H. Hung, Y.D. Yao, C.K. Lin, J. Appl. Phys. 107, 09A502-1–09A502-3 (2010)

C. Boudaya, L. Laroussi, E. Dhahri, J.C. Joubert, A. Cheikhrouhou, J. Phys. Condens. Matter 10, 7485–7492 (1998)

J.R. Liu, M. Itoh, K. Machida, Appl. Phys. Lett. 83, 4017–4019 (2003)

S. Huang, L. Deng, K. Zhou, Z. Hu, S. Sun, Y. Ma, P. Xiao, J. Magn. Magn. Mater. 324, 3149–3153 (2012)

S. Zhao, J. Zheng, F. Jiang, Y. Song, M. Sun, X. Song, J. Mater. Sci.: Mater. Electron. 26, 1–6 (2015)

F. Jiang, J. Zheng, L. Liang, M. Zhang, Y. Wang, J. Mater. Sci.: Mater. Electron. 26, 2243–2247 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, S., Zheng, J., Shi, B. et al. The microwave absorbing properties of La0.8K0.2MnO3 synthesized by sol–gel method. J Mater Sci: Mater Electron 28, 1168–1173 (2017). https://doi.org/10.1007/s10854-016-5642-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5642-7