Abstract

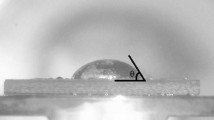

The solder process comprises the ability of a melted alloy to flow or spread on a substrate for the formation of a metallic bond driven by the physical–chemical properties of the system. Thus, the study of wetting behaviour is an important step in the characterisation of solder alloys and requires the discussion of different parameters that affect the solder junctions. The main objective of this work is to use a CFD study to determine the influence of several parameters in the melting shape obtained with a solder, of the SAC 305 type and compare the numerical results with experimental data. The computational model was implemented in ANSYS Fluent® and the simulations were carried out involving the melting of a material using the volume of fluid method to capture the solidification/melting interfaces based on an enthalpy-porosity approach. The results show that shape of the melted solder is greatly influenced by the contact angle and, to a smaller extent, by the surface tension. It was also concluded that it is possible to accurately predict the shape of the melted solder using computational fluid dynamic tools in complement to the experimental validation.

Similar content being viewed by others

References

C.S. Lau, M.Z. Abdullah, F. Che Ani, Optimization modeling of the cooling stage of reflow soldering process for ball grid array package using the gray-based Taguchi method. Microelectron. Reliab. 52, 1143–1152 (2012). doi:10.1016/j.microrel.2012.01.006

M. Liukkonen, E. Havia, H. Leinonen, Y. Hiltunen, Quality-oriented optimization of wave soldering process by using self-organizing maps. Appl. Soft. Comput. J. 11, 214–220 (2011). doi:10.1016/j.asoc.2009.11.011

D.C. Whalley, A simplified reflow soldering process model. J. Mater. Process. Technol. 150, 134–144 (2004). doi:10.1016/j.jmatprotec.2004.01.029

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Eng. R Rep. 27, 95–141 (2000). doi:10.1016/S0927-796X(00)00010-3

C. Gonçalves, H. Leitão, C.S. Lau, J.C. Teixeira, L. Ribas, S. Teixeira et al., Wetting behaviour of SAC305 solder on different substrates in high vacuum and inert atmosphere. J. Mater. Sci. Mater. Electron. 26, 5106–5112 (2015). doi:10.1007/s10854-015-3037-9

F. Xing, J. Yao, J. Liang, X. Qiu, Influence of intermetallic growth on the mechanical properties of Zn–Sn–Cu–Bi/Cu solder joints. J. Alloys Compd. 649, 1053–1059 (2015). doi:10.1016/j.jallcom.2015.07.231

Urbánek J, Dušek K. Measurements of the solders surface tension values. In: 7th Int Conf Therm Mech Multiphysics Simul Exp Micro-Electronics Micro-Systems, EuroSimE 2006 2006;2006:7–10. doi:10.1109/ESIME.2006.1643983

D. Bonn, J. Eggers, J. Indekeu, J. Meunier, Wetting and spreading. Rev Mod Phys 81, 739–805 (2009). doi:10.1103/RevModPhys.81.739

Z. Moser, W. Gąsior, A. Dębski, J. Pstruś, Database of lead—free soldering materials surface tension, density and molar volume (Institute of Metallurgy and Materials Science Polish Academy of Science, Poland, 2007). http://www.imim.pl/files/Surdat/SURDAT.pdf

J.D. Malcolm, C.D. Elliott, Interfacial tension from height and diameter of a single sessile drop or captive bubble. Can. J. Chem. Eng. 58, 151–153 (1980). doi:10.1002/cjce.5450580203

Yuan Y, Lee TR. Chapter 1—Contact Angle and Wetting Properties, ed. by G. Bracco, B. Holst, Surf. Sci. Technol., vol. 51 (Berlin, Heidelberg: Springer Berlin Heidelberg, 2013). doi:10.1007/978-3-642-34243-1

F. Bashforth, J.C. Adams, An Attempt to Test the Theories of Capillary Action (Cambridge [Eng.] University Press, Cambridge, 1892)

O. Del Río, A. Neumann, Axisymmetric drop shape analysis: computational methods for the measurement of interfacial properties from the shape and dimensions of pendant and sessile drops. J. Colloid Interface Sci. 196, 136–147 (1997). doi:10.1006/jcis.1997.5214

A. Siewiorek, A. Kudyba, N. Sobczak, M. Homa, Z. Huber, Z. Adamek et al., Effects of PCB substrate surface finish and flux on solderability of lead-free SAC305 alloy. J. Mater. Eng. Perform. 22, 2247–2252 (2013). doi:10.1007/s11665-013-0492-4

S. Amore, E. Ricci, G. Borzone, R. Novakovic, Wetting behaviour of lead-free Sn-based alloys on Cu and Ni substrates. Mater. Sci. Eng. A 495, 108–112 (2008). doi:10.1016/j.msea.2007.10.110

Costa J, Soares D, Teixeira S, Cerqueira F, Macedo F, Rodrigues N, et al. Modeling the reflow soldering process in PCB’s. In: International conference on exhibition on packaging and integration of electronics. photonic microsystems interpack2015, San Francisco, USA: 2015, pp. 1–6

F.S. Ismail, R. Yusof, M. Khalid, Optimization of electronics component placement design on PCB using self organizing genetic algorithm (SOGA). J. Intell. Manuf. 23, 883–895 (2012). doi:10.1007/s10845-010-0444-x

W. Ho, P. Ji, P.K. Dey, Optimization of PCB component placements for the collect-and-place machines. Int. J. Adv. Manuf. Technol. 37, 828–836 (2008). doi:10.1007/s00170-007-1014-z

C.-S. Lau, M.Z. Abdullah, F.C. Ani, Three-dimensional thermal investigations at board level in a reflow oven using thermal-coupling method. Solder Surf. Mt. Technol. 24, 167–182 (2012). doi:10.1108/09540911211240038

ANSYS. ANSYS Fluent 15.0 Theory Guide. (2014)

ANSYS. ANSYS Meshing User’s Guide. Canonsburg, PA, USA: ANSYS Inc; (2011)

Acknowledgments

The authors acknowledge the financial support provided through project SI I&DT Projeto em co promoção No. 36265/2013 (Projeto HMIEXCEL—2013–2015). This work has been supported by COMPETE and Portuguese Foundation for Science and Technology (FCT) within: Strategic Project: UID/CEC/00319/2013; Strategic Project UID/SEM/04077/2013; and Strategic Project UID/EEA/04436/2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodrigues, N., Ferreira, A.C., Teixeira, S.F. et al. Contact angle measurement of SAC 305 solder: numerical and experimental approach. J Mater Sci: Mater Electron 27, 8941–8950 (2016). https://doi.org/10.1007/s10854-016-4924-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4924-4