Abstract

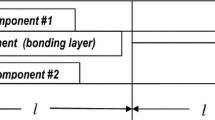

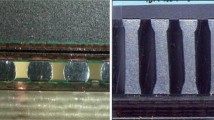

It is shown, based on the developed analytical predictive model, that a significant thermal stress relief can be achieved in an optimized design of an inhomogeneously bonded bi-material assembly, if its bonding system is designed in such a way that the interfacial shearing stress at the ends of the high-modulus-and-high-bonding-temperature mid-portion of the assembly at its boundary with the low-modulus-and-low-bonding-temperature peripheral portion is made equal to the stress at the assembly ends. The numerical example carried out for such an optimized ball-grid-array (BGA) or a column-grid-array (CGA) electronic assembly indicates that the above measure enables one to design an assembly, in which the induced interfacial stresses are about half of the stresses in a regular, non-optimized, but still inhomogeneously bonded assembly with a low-modulus-and/or-low-bonding-temperature material at its ends. The predicted maximum stress in an optimized assembly is only about 41 % of the maximum stress in a homogeneously bonded BGA assembly and about 46 % of the maximum stress in a homogeneously bonded CGA assembly. The numerical data indicated also that the application of the CGA technology in a non-optimized inhomogeneously bonded assembly enables one to achieve a 19 % stress relief in the case of an application of the epoxy adhesive at the peripheral portions of the assembly, and that a 34 % stress relief could be expected in the case of the use of a low modulus solder at the assembly ends. When a BGA technology is considered, the application of an epoxy or a low modulus solder at the peripheral portions of the assembly leads to approximately the same stress relief effect: about 14 % in the case of an epoxy adhesive and about 13 % in the case of a low modulus solder. When a CGA technology is considered, the application of an epoxy at the peripheral portions of the non-optimized assembly leads to about 9.0 % stress relief, while the application of a low modulus solder results in about 24 % stress relief. If, e.g., the yield stress in shear is 1.85 kg/mm2 for the solder in the assembly’s mid-portion and 1.35 kg/mm2 for the peripheral solder material, the application of the CGA technology in combination with an inhomogeneous bond with an epoxy adhesive or a low modulus solder at the assembly ends might enable one to avoid inelastic strains in the solder, weather in the mid-portion or in the peripheral portion, thereby increasing dramatically the fatigue lifetime of the bond. It is even easier to achieve this goal with the use of the suggested optimized design of an inhomogeneous bond.

Similar content being viewed by others

References

E. Suhir, ‘‘Global’’ and ‘‘Local’’ thermal mismatch stresses in an elongated bi-material assembly bonded at the ends, in Structural Analysis in Microelectronic and Fiber-Optic Systems, Symposium Proceedings, ed. by E. Suhir (ASME Press, New York, 1995), pp. 101–105

E. Suhir, Predicted thermal mismatch stresses in a cylindrical bi-material assembly adhesively bonded at the ends. ASME J. Appl. Mech. 64(1), 15–22 (1997)

E. Suhir, Thermal stress in a polymer coated optical glass fiber with a low modulus coating at the ends. J. Mater. Res. 16(10), 2996–3004 (2001)

E. Suhir, Thermal stress in a bi-material assembly adhesively bonded at the ends. J. Appl. Phys. 89(1), 120–129 (2001)

E. Suhir, Thermal stress in an adhesively bonded joint with a low modulus adhesive layer at the ends. J. Appl. Phys. 55, 3657–3661 (2003)

E. Suhir, L. Bechou, B. Levrier, Predicted size of an inelastic zone in a ball-grid-array assembly. ASME J. Appl. Mech. 80, 021007-1–021007-5 (2013)

E. Suhir, Interfacial thermal stresses in a bi-material assembly with a low-yield-stress bonding layer. Model. Simul. Mater. Sci. Eng. 14, 1421 (2006)

E. Suhir, A. Shakouri, Assembly bonded at the ends: could thinner and longer legs result in a lower thermal stress in a thermoelectric module (TEM) design? ASME J. Appl. Mech. 79(6), 061010-1–061010-8 (2012)

E. Suhir, On a paradoxical situation related to bonded joints: could stiffer mid-portions of a compliant attachment result in lower thermal stress? JSME J. Solid Mech. Mater. Eng. JSMME 3(7), 990–997 (2009)

E. Suhir, Thermal stress in a bi-material assembly with a ‘‘piecewise-continuous’’ bonding layer: theorem of three axial forces. J. Appl. Phys. D 42, 045507-1–045507-7 (2009)

E. Suhir, Adhesively bonded assemblies with identical nondeformable adherends and inhomogeneous adhesive layer: predicted thermal stresses in the adhesive. J. Reinf. Plast. Compos. 17(14), 1588–1606 (1998)

E. Suhir, Adhesively bonded assemblies with identical nondeformable adherends and ‘‘piecewise continuous’’ adhesive layer: predicted thermal stresses and displacements in the adhesive. Int. J. Solids Struct. 37, 2229–2252 (2000)

E. Suhir, Analysis of a short beam with application to solder joints: could larger stand-off heights relieve stress? Eur. Phys. J. Appl. Phys. EPJAP 71, 31301 (2015)

E. Suhir, R. Ghaffarian, J. Nicolics, Could application of column-grid-array technology result in inelastic-strain-free state-of-stress in solder material? J. Mater. Sci. Mater. Electron. 26, 10062–10067 (2015)

E. Suhir, Stresses in bi-metal thermostats. ASME J. Appl. Mech. 53(3), 657–660 (1986)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suhir, E. Expected stress relief in a bi-material inhomogeneously bonded assembly with a low-modulus-and/or-low-fabrication-temperature bonding material at the ends. J Mater Sci: Mater Electron 27, 5563–5574 (2016). https://doi.org/10.1007/s10854-016-4461-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4461-1