Abstract

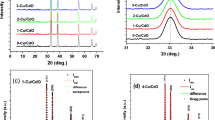

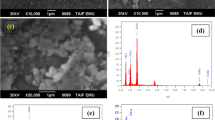

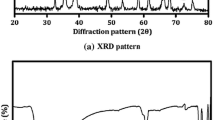

A series of Cu(Cr1−xFex)O2 and Cu(Cr1−yMgy)O2 (0.0 ≤ x,y ≤ 0.05) nanocrystalline samples with high surface area were prepared using hydrothermal synthesis. The effect of Fe3+ substitution for Cr3+ on the structural, morphological, optical and electrical characteristics of CuCrO2 nanoparticles was investigated in comparison with Mg-doped samples. X-ray diffraction study showed that the solubility limit was around 3 at% for both dopants and beyond this concentration the formation of spinel phases was observed. The incorporation of the tri- and divalent dopants induced a slight expansion in a- and c-parameters. Transmission electron microscopy examination indicated that the average crystallite size (12 nm for undoped) decreased with increasing doping amount of up to x = 0.03 (8.5 nm) and y = 0.05 (7 nm). Moreover, the introduction of Fe and Mg led to an increase in the size distribution of the crystallites. All samples exhibited transmittance above 80 % at 700 nm wavelength and transmittance was enhanced for all doping concentrations except for x = 0.05. A similar trend was also observed for the direct band gaps, where only 5 at% Fe doping induced a red-shift of Eg. The direct band gaps were estimated to be 3.09 eV for x = 0.03 and 3.07 eV for y = 0.03. At room temperature, the minimum achieved electrical resistivity was measured to be 6.4 and 0.068 kΩ cm for the samples with x,y = 0.03, respectively. These values are lower by a factor of ~2 and 166 than that of the undoped CuCrO2 sample (11.8 kΩ cm). All samples behaved like semiconductors, and the thermally activated energy for Cu(Cr0.97Mg0.03)O2 and Cu(Cr0.97Fe0.03)O2 pellets were found to be 45.40 and 92.5 meV, respectively.

Similar content being viewed by others

References

A.N. Banerjee, K.K. Chattopadhyay, Prog. Cryst. Growth Charact. 50, 52 (2005)

H. Kawazoe, M. Yasukawa, H. Hyodo, M. Kurita, H. Yanagi, H. Hosono, Nature 389, 939 (1997)

S. Nandy, A. Banerjee, E. Fortunato, R. Martins, Rev. Adv. Sci. Eng. 2, 273 (2013)

B. Szyszka, W. Dewald, S.K. Gurram, A. Pflug, C. Schulz, M. Siemers, V. Sittinger, S. Ulrich, Curr. Appl. Phys. 12, 2 (2012)

M. Neumann-Spallart, S.P. Pai, R. Pinto, Thin Solid Films 515, 8641 (2007)

H. Yanagi, H. Kawazoe, A. Kudo, M. Yasukawa, H. Hosono, J. Electroceram. 4, 407 (2000)

S. Götzendörfer, C. Polenzky, S. Ulrich, P. Löbmann, Thin Solid Films 518, 1153 (2009)

H.F. Jiang, X.B. Zhu, H.C. Lei, G. Li, Z.R. Yang, W.H. Song, J.M. Dai, Y.P. Sun, Y.K. Fu, Thin Solid Films 519, 2559 (2011)

S.Y. Zheng, G.S. Jiang, J.R. Su, C.F. Zhu, Mater. Lett. 60, 3871 (2006)

H.-Y. Chen, C.-C. Yang, Surf. Coat. Technol. 231, 277 (2013)

T. Elkhouni, M. Amami, C.V. Colin, P. Strobel, A.B. Salah, J. Magn. Magn. Mater. 330, 101 (2013)

T. Okuda, T. Onoe, Y. Beppu, N. Terada, T. Doi, S. Miyasaka, Y. Tokura, J. Magn. Magn. Mater. 310, 890 (2007)

Y. Wang, Y. Gu, T. Wang, W. Shi, J. Alloys Compd. 509, 5897 (2011)

T.-W. Chiu, S.-W. Tsai, Y.-P. Wang, K.-H. Hsu, Ceram. Int. 38, 673 (2012)

R. Nagarajan, A.D. Draeseke, A.W. Sleight, J. Tate, J. Appl. Phys. 89, 8022 (2001)

X. Zhou, F. Lin, W. Shi, A. Liu, J. Alloys Compd. 614, 221 (2014)

M. Amami, C.V. Colin, P. Strobel, A.B. Salah, Phys. B 406, 2182 (2011)

F. Lin, W. Shi, A. Liu, J. Alloys Compd. 529, 21 (2012)

C. Gao, F. Lin, X. Zhou, W. Shi, A. Liu, J. Alloys Compd. 565, 154 (2013)

F. Lin, C. Gao, X. Zhou, W. Shi, A. Liu, J. Alloys Compd. 581, 502 (2013)

K. Park, K.Y. Ko, H.C. Kwon, S. Nahm, J. Alloys Compd. 437, 1 (2007)

K. Hayashi, K. Sato, T. Nozaki, T. Kajitani, Jpn. J. Appl. Phys. 47, 59 (2008)

Z. Deng, X. Fang, D. Li, S. Zhou, R. Tao, W. Dong, T. Wang, G. Meng, X. Zhu, J. Alloys Compd. 484, 619 (2009)

Y. Ma, X. Zhou, Q. Ma, A. Litke, P. Liu, Y. Zhang, C. Li, E.J.M. Hensen, Catal. Lett. 144, 1487 (2014)

S. Saadi, A. Bouguelia, M. Trari, Sol. Energy 80, 272 (2006)

D. Xiong, Z. Xu, X. Zeng, W. Zhang, W. Chen, X. Xu, M. Wang, Y.-B. Cheng, J. Mater. Chem. 22, 24760 (2012)

X.B. Xu, J. Cui, J.B. Han, J.P. Zhang, Y.B. Zhang, L. Luan, G. Alemu, Z. Wang, Y. Shen, D.H. Xiong, W. Chen, Z.H. Wei, S.H. Yang, B. Hu, Y.B. Cheng, M.K. Wang, Sci. Rep-UK. 4, 3961 (2014)

D.H. Xiong, W.J. Zhang, X.W. Zeng, Z. Xu, W. Chen, J. Cui, M.K. Wang, L.C. Sun, Y.B. Cheng, Chemsuschem 6, 1432 (2013)

J. Wang, P. Zheng, D. Li, Z. Deng, W. Dong, R. Tao, X. Fang, J. Alloys Compd. 509, 5715 (2011)

T.-W. Chiu, Y.-T. Chen, Ceram. Int. 41, 407 (2015)

S. Zhou, X. Fang, Z. Deng, D. Li, W. Dong, R. Tao, G. Meng, T. Wang, X. Zhu, J. Cryst. Growth 310, 5375 (2008)

M. Miclau, D. Ursu, S. Kumar, I. Grozescu, J. Nanopart. Res. 14, 1110 (2012)

D. Friedrich, C. Wockel, S. Küsel, R. Konrath, H. Krautscheid, R. Denecke, B. Abel, Am. J. Nano Res. Appl. 2, 53 (2014)

D.H. Ursu, M. Miclău, R. Bănică, I. Grozescu, Phys. Scripta. T157, 014053 (2013)

A. Maignan, C. Martin, R. Fresard, V. Eyert, E. Guilmeau, S. Hebert, M. Poienar, D. Pelloquin, Solid State Commun. 149, 962 (2009)

R.D. Shannon, Acta Cryst. A32, 751 (1976)

A. Barnabé, Y. Thimont, M. Lalanne, L. Presmanes, P. Tailhades, J. Mater. Chem. C 3, 6012 (2015)

P.W. Sadik, M. Ivill, V. Craciun, D.P. Norton, Thin Solid Films 517, 3211 (2009)

Y. Ono, K.-I. Satoh, T. Nozaki, T. Kajitani, Jpn. J. Appl. Phys. 46, 1071 (2007)

R. Bywalez, S. Gotzendorfer, P. Lobmann, J. Mater. Chem. 20, 6562 (2010)

V.M. Ustyantsev, V.P. Marevich, G.G. Lopachok, Inorg. Mater. 16, 496 (1980)

D. Li, X.D. Fang, Z.H. Deng, W.W. Dong, R.H. Ta, S. Zhou, J.M. Wang, T. Wang, Y.P. Zha, X.B. Zhu, J. Alloys Compd. 486, 462 (2009)

J.I. Pankove, Optical Processes in Semiconductors (Prentice Hall, Englewood Cliffs, 1971)

R.S. Yu, D.H. Hu, Ceram. Int. 41, 9383 (2015)

K. Oshiro, K. Akai, M. Matsuura, Phys. Rev. B 59, 10850 (1999)

N. Goswami, D.K. Sharma, Phys. E 42, 1675 (2010)

Y. Kayanuma, Phys. Rev. B 38 9797 (1988)

S. Gotzendorfer, P. Lobmann, J. Sol-Gel Sci. Technol. 57, 157 (2011)

E. Guilmeau, M. Poienar, S. Kremer, S. Marinel, S. Hebert, R. Fresard, A. Maignan, Solid State Commun. 151, 1798 (2011)

Q.G. Meng, S.F. Lu, S.H. Lu, Y. Xiang, J. Sol-Gel Sci. Technol. 63, 1 (2012)

N.K. Liu, B.S. Zhu, J.S. Luo, Semiconductor Physics (Electronic Industry Press, Beijing, 2008)

Acknowledgments

Support for this work is provided by the Scientific Research Foundation (BAP) of Selçuk University (Project Number 14401104),TUBITAK MAG (Project Number 214M410) and Academic Staff Training Program (ÖYP) (Project Number 2013-ÖYP-087) which authors gratefully acknowledge.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaya, İ.C., Sevindik, M.A. & Akyıldız, H. Characteristics of Fe- and Mg-doped CuCrO2 nanocrystals prepared by hydrothermal synthesis. J Mater Sci: Mater Electron 27, 2404–2411 (2016). https://doi.org/10.1007/s10854-015-4038-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4038-4