Abstract

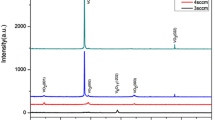

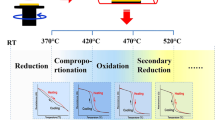

Vanadium oxide (VOx) thin films were fabricated on the sapphire substrates by sputtering deposition and subsequent rapid-thermal-annealing (RTA) process. The effect of O2 flow rate on the crystal structure, surface morphology and phase transition property of thin films was studied. The results indicated that VOx thin films were polycrystalline structures and consisted of irregular blocky-shaped grains. As the O2 flow rate increased from 3 to 4.5 slpm, the oxidation was enhanced and the grain size decreased gradually. In addition, when we increased O2 flow rate, phase transition amplitude increased from 5.4 to 117 and the phase transition temperature decreased from 50.45 °C to 45.37 °C. The hysteresis width almost increased as O2 flow rate increased. More interesting, we found that the value of \(d\lg {\text{R}}_{\square } /dT\) became big at high temperature which could be attributed to the phase transition and the variation trend of difference was in line with the phase transition amplitude. So, it could be concluded that O2 flow rate in the RTA process played a significant role in the properties of VOx thin films.

Similar content being viewed by others

References

P. Limelette, A. Georges, D. Jerome, P. Wzietek, P. Metcalf, J.M. Honig, Science 302, 89–92 (2003)

Z.S. El Mandouh, M.S. Selim, Thin Solid Films 371, 259–263 (2000)

Y.Y. Luo, L.Q. Zhu, Y.X. Zhang, S.S. Pan, S.C. Xu, M. Liu, G.H. Li, J. Appl. Phys. 113, 183520 (2013)

E.M. Heckman, L.P. Gonzalez, S. Guha, J.O. Barnes, A. Carpenter, Thin Solid Films 518, 265–268 (2009)

M.M. Rahman, J.Z. Wang, N.H. Idris, Z.X. Chen, H.K. Liu, Electrochim. Acta 56, 693–699 (2010)

T. Driscoll, H.T. Kim, B.G. Chae, B.J. Kim, Y.W. Lee, N.M. Jokerst, S. Palit, D.R. Smith, M.D. Ventra, D.N. Basov, Science 325, 1518–1521 (2009)

G. Seo, B.J. Kim, L.Y. Wook, H.T. Kim, Appl. Phys. Lett. 100, 011908 (2012)

M.J. Lee, Y. Park, D.S. Suh, E.H. Lee, S. Seo, D.C. Kim, R. Jung, B.S. Kang, S.E. Ahn, C.B. Lee, Adv. Mater. 19, 3919–3923 (2007)

Z.L. Huang, S.H. Chen, C.H. Lv, Y. Huang, J.J. Lai, Appl. Phys. Lett. 101, 191905 (2012)

Z.L. Huang, S.H. Chen, B.Q. Wang, Y. Huang, N.F. Liu, J. Xu, J.J. Lai, Thin Solid Films 519, 4246–4248 (2011)

M. Soltani, M. Chaker, E. Haddad, R.V. Kruzelecky, J. Margot, Appl. Phys. Lett. 85, 1958–1960 (2004)

M.B. Sahana, M.S. Dharmaprakash, S.A. Shivashankar, J. Mater. Chem. 12, 333–338 (2002)

D. Vernardou, M.E. Pemble, D.W. Sheel, Chem. Vap. Depos. 12, 263–274 (2006)

D. Vernardou, D. Louloudakis, E. Spanakis, N. Katsarakis, E. Koudoumas, Sol. Energy Mater. Sol. Cells 128, 36–40 (2014)

C. Ba, S.T. Bah, M. D’Auteuil, P.V. Ashrit, R. Vallee, A.C.S. Appl, Mater. Interfaces 5, 12520–12525 (2013)

J.B.K. Kana, J.M. Ndjaka, P.O. Ateba, B.D. Ngom, N. Manyala, O. Nemraoui, A.C. Beye, M. Maaza, Appl. Surf. Sci. 254, 3959–3963 (2008)

Z.F. Luo, X. Zhou, D.W. Yan, D. Wang, Z.Y. Li, C.B. Yang, Y.D. Jiang, Thin Solid Films 550, 227–232 (2014)

L. Mathevula, B.D. Ngom, L. Kotsedi, P. Sechogela, T.B. Doyle, M. Ghouti, M. Maaza, Appl. Surf. Sci. 314, 476–480 (2014)

J. Sakai, M. Zaghrioui, V.T. Phuoc, S. Roger, C. Autret-Lambert, K. Okimura, J. Appl. Phys. 113, 123503 (2013)

Y.X. Guo, Y.F. Liu, C.W. Zou, Z.W. Qi, Y.Y. Wang, Y.Q. Xu, X.L. Wang, F. Zhang, R. Zhou, Appl. Phys. A 115, 1245–1250 (2013)

J. Leroy, A. Bessaudou, F. Cosset, A. Crunteanu, Structural. Thin Solid Films 520, 4823–4825 (2012)

R.E. Marvel, K. Appavoo, B.K. Choi, J. Nag, R.F. Haglund, Appl. Phys. A 111, 975–981 (2013)

C. Zhang, W. Cao, A.V. Adedeji, H.E. Elsayed-Ali, J. Sol–gel Sci. Technol. 69, 320–324 (2013)

J. Wu, W.X. Huang, Q.W. Shi, J.H. Cai, D. Zhao, Y.B. Zhang, J.Z. Yan, Appl. Surf. Sci. 268, 556–560 (2013)

Y.J. Xu, W.X. Huang, Q.W. Shi, Y.B. Zhang, J. Wu, L.W. Song, J. Mater. Sci.: Mater. Electron. 24, 3823–3829 (2013)

L.L. Fan, S. Chen, Y.F. Wu, F.H. Chen, W.S. Chu, X. Chen, C.W. Zou, Z.Y. Wu, Appl. Phys. Lett. 103, 131914 (2013)

S. Kittiwatanakul, J. Laverock, D. Newby, K.E. Smith, S.A. Wolf, J.W. Lu, J. Appl. Phys. 114, 053703 (2013)

H.F. Zhang, Z.M. Wu, Q. He, Y.D. Jiang, Appl. Surf. Sci. 277, 218–222 (2013)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grants 61471264 and 61101055). We thank the Analytical & Testing Center of Tianjin University for the XRD analysis.

Conflict of interest

We declare that there is not conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, N., Hu, M., Liang, JR. et al. Effect of O2 flow rate in the annealing process on metal–insulator transition of vanadium oxide thin films. J Mater Sci: Mater Electron 26, 6920–6925 (2015). https://doi.org/10.1007/s10854-015-3310-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3310-y