Abstract

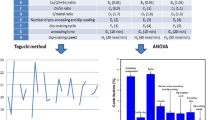

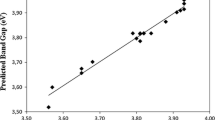

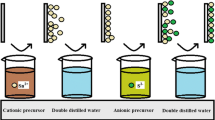

In this study, CuS thin films were deposited on glass substrates by SILAR method with different pH, dipping time and dipping cycles. For the first time, response surface methodology was used for optimization CuS thin film coating parameters. 5-level-3-factor central composite design was employed to evaluate the effects of the deposition parameters (pH, dipping time and dipping cycles) on the optical band gap of the films. The significant level of the main effects and the interactions were investigated by analysis of variance. The morphological, structural and optical properties of the films were investigated by SEM, XRD and UV–Vis. The optimum pH, dipping time and dipping cycles were found to be 11.5, 31 s and 15 cycles, respectively. Under these conditions, the experimental band gap of CuS was observed as 2.18 eV which was well in close agreement with predicted value (2.11 eV) by the model. Quality of the film was improved after chemometrics optimization.

Similar content being viewed by others

References

A. Bollero, M. Grossberg, B. Asenjo, M.T. Gutierrez, Surf. Coat. Technol. 204, 593–600 (2009)

Y. Lu, X. Meng, G. Yi, J. Jia, J. Colloid Interface Sci. 356, 726–733 (2011)

B. Bharathi, S. Thanikaikarasan, P. Kollu, P.V. Chandrasekar, K. Sankaranarayanan, X.S. Shajan, J. Mater. Sci.: Mater. Electron. 25, 5338–5344 (2014)

S.M. Pawar, B.S. Pawar, J.H. Kim, O.S. Joo, C.D. Lokhande, Curr. Appl. Phys. 11, 117–161 (2011)

S. Lindroos, A. Arnold, M. Leskel, Appl. Surf. Sci. 158, 75–80 (2000)

S.D. Sartale, C.D. Lokhande, Mater. Chem. Phys. 65, 63–67 (2000)

M.A. Yildirim, A. Ates, A. Astam, Phys. E 41, 1365–1372 (2009)

R.G. Brereton, Chemometrics: Data Analysis for the Laboratory and Chemical Plant (Wiley, London, 2003)

E. Yücel, Y. Yücel, İ. Belenli, J. Mater. Sci.: Mater. Electron. 23, 1284–1292 (2012)

Y. Yücel, Fuel Process. Technol. 99, 97–102 (2012)

Y. Yücel, Biocatal. Agric. Biotechnol. 1, 39–44 (2012)

L. Sun, S. Wan, Z. Yu, L. Wang, Sep. Purif. Technol. 125, 156–162 (2014)

C. Saikaew, A. Wisitsoraat, R. Sootticoon, Surf. Coat. Technol. 204, 1493–1502 (2010)

C.L. Tien, S.W. Lin, Opt. Commun. 266, 574–581 (2006)

E. Yücel, N. Güler, Y. Yücel, J. Alloy. Compd. 589, 207–212 (2014)

E. Yücel, Y. Yücel, J. Mater. Sci.: Mater. Electron. 26, 196–203 (2015)

E. Guneri, A. Kariper, J. Alloy. Compd. 516, 20–26 (2012)

R. Sun, H.Y. Zhang, G.G. Wang, J.C. Han, X.Z. Wang, L. Cui, X.P. Kuang, C. Zhu, L. Jin, Superlattice Microstruct. 65, 146–151 (2014)

Y. Akaltun, M.A. Yıldırım, A. Ateş, M. Yıldırım, Opt. Commun. 284, 2307–2311 (2011)

A. Taner, M. Kul, E. Turan, A.Ş. Aybek, M. Zor, T. Taşköprü, Thin Solid Films 520, 1358–1362 (2011)

Acknowledgments

This work is financially supported by the Scientific Research Commission of Mustafa Kemal University (Project No: 11700).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yücel, Y., Yücel, E. & Gökhan, D. Optimization and modelling of preparation conditions of CuS thin films deposited by successive ionic layer adsorption and reaction (SILAR) method using response surface methodology. J Mater Sci: Mater Electron 26, 4105–4112 (2015). https://doi.org/10.1007/s10854-015-2952-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2952-0