Abstract

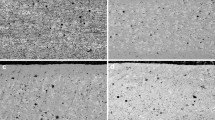

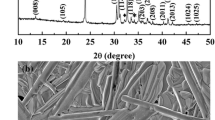

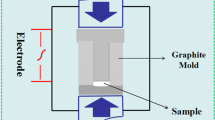

Bi2Sr2Co1.8Ox ceramics have been synthesized through solid-state reaction methods and directionally grown from the melt by laser floating zone technique. Mechanical and thermoelectric characteristics of this material were determined by three point bending tests and the four probe technique, respectively. The mechanical and thermoelectric properties of Bi2Sr2Co1.8Ox were determined as a function of the environmental conditions, air and water. Flexural strength data show that textured materials possess a high degradation resistance due to the low porosity of the external part of the rods (~65 µm), which avoids water infiltration and, as a consequence, the internal degradation. Moreover, power factor values are maintained practically unchanged for the samples immersed in water for 24 h.

Similar content being viewed by others

References

I. Terasaki, Y. Sasago, K. Uchinokura, Phys. Rev. B 56, 12685 (1997)

P.H. Xiang, Y. Kinemuchi, H. Kaga, K. Watari, J. Alloys Compd. 454, 364 (2008)

J.C. Diez, Sh. Rasekh, G. Constantinescu, M.A. Madre, M.A. Torres, A. Sotelo, Ceram. Int. 38, 5419 (2012)

A. Sotelo, M.A. Torres, M.A. Constantinescu, Sh. Rasekh, J.C. Diez, M.A. Madre, J. Eur. Ceram. Soc. 32, 3745 (2012)

J.C. Diez, Sh. Rasekh, M.A. Madre, E. Guilmeau, S. Marinel, A. Sotelo, J. Electron. Mater. 39, 1601 (2010)

M.A. Madre, Sh. Rasekh, J.C. Diez, A. Sotelo, Mater. Lett. 64, 2566 (2010)

A. Maignan, S. Hébert, M. Hervieu, C. Michel, D. Pelloquin, D. Khomskii, J. Phys. Condens. Matter 15, 2711 (2003)

A. Sotelo, Sh. Rasekh, E. Guilmeau, M.A. Madre, M.A. Torres, S. Marinel, J.C. Diez, Mater. Res. Bull. 46, 2537 (2011)

D. Kenfaui, D. Chateigner, M. Gomina, J.G. Noudem, J. Alloys Compd. 490, 472 (2010)

M.A. Torres, A. Sotelo, Sh. Rasekh, M.A. Constantinescu, J.C. Diez, M.A. Madre, Bol. Soc. Esp. Ceram. 51, 1 (2012)

D.M. Rowe, Thermoelectrics Handbook: Macro to Nano, 1st edn. (CRC Press, Boca Raton, 2006)

M. Prevel, O. Perez, J.G. Noudem, Solid State Sci. 9, 231 (2007)

M.M. Seabaugh, I.H. Kerscht, C.L. Messing, J. Am. Ceram. Soc. 80, 1181 (1997)

Sh. Rasekh, N.M. Ferreira, F.M. Costa, G. Constantinescu, M.A. Madre, M.A. Torres, J.C. Diez, A. Sotelo, Scr. Mater. 80, 1 (2014)

D. Lee Sr, R.A. Kondrate, J.A. Taylor, Physica C 350, 1 (2001)

S.G. Jin, Z.Z. Zhu, L.M. Liu, Y.L. Huang, Solid State Commun. 74, 1087 (1990)

Sh. Rasekh, G. Constantinescu, M.A. Torres, M.A. Madre, J.C. Diez, A. Sotelo, Adv. Appl. Ceram. 111, 490 (2012)

T. Itoh, I. Terasaki, Jpn. J. Appl. Phys. 39, 6658 (2000)

M. Kato, Y. Goto, K. Umehara, K. Hirota, K. Yoshimura, Physica B 378–380, 1062 (2006)

D. Mercurio, J.C. Champarnaud-Mesjard, B. Frit, P. Conflant, J.C. Boivin, T. Vogt, J. Solid State Chem. 112, 1 (1994)

K. Iwasaki, H. Yamane, T. Murase, M. Yoshino, T. Ito, T. Nagasaki, Y. Arita, T. Matsui, J. Ceram. Soc. Jpn. 117, 89 (2009)

N.M. Ferreira, Sh. Rasekh, F.M. Costa, M.A. Madre, A. Sotelo, J.C. Diez, M.A. Torres, Mater. Lett. 83, 144 (2010)

G.F. Fuente, M.T. Ruiz, A. Sotelo, A. Larrea, R. Navarro, Mater. Sci. Eng. A 173, 201 (1993)

D. Munz, T. Fett, Ceramics: Mechanical Properties, Failure Behaviour, Materials Selection (Springer, Berlin, 2001)

S.R. Choi, N.N. Nemeth, J.P. Gyekenyesi, Fatigue Fract. Eng. 28, 489 (2005)

A. Sotelo, Sh. Rasekh, E. Guilmeau, M.A. Madre, M.A. Torres, S. Marinel, J.C. Diez, J. Eur. Ceram. Soc. 30, 1815 (2010)

H. Itahara, C. Xia, J. Sugiyama, T. Tani, J. Mater. Chem. 14, 61 (2004)

A. Maignan, D. Pelloquin, S. Hébert, Y. Klein, M. Hervieu, Bol. Soc. Esp. Ceram. 45, 122 (2006)

A. Sotelo, E. Guilmeau, M.A. Madre, S. Marinel, S. Lemonnier, J.C. Diez, Bol. Soc. Esp. Ceram. 47, 225 (2008)

Acknowledgments

The authors acknowledge financial support from the Gobierno de Aragón and the Fondo Social Europeo (Consolidated Research Groups T12 and T87) and MINECO-FEDER (Project MAT2013-46505-C3-1-R). The technical contribution of C. Estepa, and C. Gallego are also acknowledged. F. Kahraman acknowledges a financial grant from the Council of Higher Education (YÖK) in Turkey for international mobility. Authors would like to acknowledge the use of Servicio General de Apoyo a la Investigación-SAI, Universidad de Zaragoza.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kahraman, F., Sotelo, A., Madre, M.A. et al. Mechanical and thermoelectric environmental evolution properties of Bi2Sr2Co1.8Ox ceramics textured by laser floating zone technique. J Mater Sci: Mater Electron 26, 1461–1465 (2015). https://doi.org/10.1007/s10854-014-2562-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2562-2