Abstract

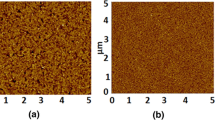

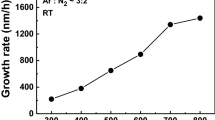

Various Si-based materials such as Si (100), Si (111), oxidized Si (SiO2), and amorphous Si (α-Si) are used as substrates for the growth of c-axis-orientated AlN thin films using radio frequency magnetron sputtering. First, AlN is studied on various substrates under a fixed deposition condition. The results show that AlN deposited on monocrystalline silicon has different structures and stress properties from it deposited on amorphous Si-based layers because of the former’s alien growth mechanism at the initiation of growth. Of all the substrates, AlN sputtered on SiO2 exhibits the best structure and morphologies. Then AlN is researched on SiO2 with the RF power and gas flow ratio of N2 to Ar varied. The results approve that among all chosen RF powers, AlN sputtered at 150 W has the strongest (002) crystal peak, the smallest root-mean-square (RMS) surface roughness of 2.74 nm, and the lowest tensile stress of 605 MPa, but the lowest deposition rate. For the gas flow ratio, AlN synthesized at the N2 to Ar flow ratio of 3:1 represents the highest intensity of (002) texture, the smoothest surface with an RMS of 4.21 nm, but the relatively lower deposition rate and larger residual stress.

Similar content being viewed by others

References

U. Figueroa, O. Salas, J. Oseguera, Surf. Coat. Technol. 200, 1768 (2005)

Z.X. Bi, Y.D. Zheng, R. Zhang, S.L. Gu, X.Q. Xiu, L.L. Zhou, B. Shen, D.J. Chen, Y. Shi, J. Mater. Sci. Mater. Electron. 15, 317 (2004)

S. Marauska, V. Hrkac, T. Dankwort, R. Jahns, H.J. Quenzer, R. Knöchel, L. Kienle, B. Wagner, Microsyst. Technol. 18, 787 (2012)

G.F. Iriarte, J.G. Rodríguez, F. Calle, Mater. Res. Bull. 45, 1039 (2010)

R.D. Vispute, J. Narayan, H. Wu, K. Jagannadham, J. Appl. Phys. 77, 4724 (1995)

G.F. Iriarte, D.F. Reyes, D. González, J.G. Rodriguez, R. García, F. Calle, Appl. Surf. Sci. 257, 9306 (2011)

E. Milyutin, S. Harada, D. Martin, J.F. Carlin, N. Grandjean, V. Savu, O. Vaszquez-Mena, J. Brugger, P. Muralt, J. Vac. Sci. Technol. B 28, L61 (2010)

A. Szekeres, Z. Fogarassy, P. Petrik, E. Vlaikova, A. Cziraki, G. Socol, C. Ristoscu, S. Grigorescu, I.N. Mihailescu, Appl. Surf. Sci. 257, 5370 (2011)

J. Bjurström, G. Wingqvist, V. Yantchev, I Katardjiev. J. Micromech. Microeng. 17, 651 (2007)

J. Olivares, E. Iborra, M. Clement, L. Vergara, J. Sangrador, A. Sanz-Hervás, Sens. Actuators A 123–124, 590 (2005)

C.K. Chung, M.Q. Tsai, P.H. Tsai, C. Lee, J. Micromech. Microeng. 15, 136 (2005)

A. Artieda, C. Sandu, P. Muralt, J. Vac. Sci. Technol. A 28, 390 (2010)

J. Olivares, J. Capilla, M. Clement, J. Sangrador, E. Iborra, IEEE international ultrasonics symposium proceedings, (IEEE, Orlando, FL, 2011), p. 1716

X.Q. Jiao, R. Zhang, J. Yang, H. Zhong, Y. Shi, X.Y. Chen, J. Shi, Appl. Phys. A 116, 621 (2014)

J.X. Zhang, H. Cheng, Y.Z. Chen, A. Uddin, S. Yuan, S.J. Geng, S. Zhang, Surf. Coat. Technol. 198, 68 (2005)

K. Dovidenko, S. Oktyabrsky, J. Narayan, M. Razeghi, J. Appl. Phys. 79, 2439 (1996)

W.K. Liu, K.W. Tay, S.C. Kuo, M.J. Wu, Sci. China Ser. G 52, 226 (2009)

A. Kale, R.S. Brusa, A. Miotello, Appl. Surf. Sci. 258, 3450 (2012)

S.H. Lee, J.K. Lee, K.H. Yoon, J. Vac. Sci. Technol. A 21, 1 (2003)

G.W. Auner, F. Jin, V.M. Naik, R. Naik, J. Appl. Phys. 85, 7879 (1999)

Y.J. Yong, J.Y. Lee, H.S. Kim, J.Y. Lee, Appl. Phys. Lett. 71, 1489 (1997)

U. Kaiser, P.D. Brown, I. Khodos, C.J. Humphreys, H.P.D. Schenk, W. Richter, J. Mater. Res. 14, 2036 (1999)

J.X. Zhang, Y.Z. Chen, H. Cheng, A. Uddin, S. Yuan, K. Pita, T.G. Andersson, Thin Solid Films 471, 336 (2005)

J.A. Thornton, Ann. Rev. Mater. Sci. 7, 239 (1977)

R.E. Sah, L. Kirste, M. Baeumler, P. Hiesinger, V. Cimalla, V. Lebedev, H. Baumann, H.-E. Zschau, J. Vac. Sci. Technol. A 28, 394 (2010)

Acknowledgments

The authors would like to acknowledge the financial support from National Natural Science Foundation of China (No. 61101038) and Sichuan Key Technology R&D Program (No. 2011GZ0220) and thank Mr. Lei Gao for the XRD measurement and Mrs. Ying Fan for her help with AFM scanning.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiao, X., Shi, Y., Zhong, H. et al. AlN thin films deposited on different Si-based substrates through RF magnetron sputtering. J Mater Sci: Mater Electron 26, 801–808 (2015). https://doi.org/10.1007/s10854-014-2467-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2467-0