Abstract

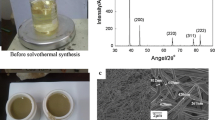

The lower resistivity (7.5 × 10−5 Ω cm) of nano-electrically conductive adhesives (nano-ECAs) with silver flakes and in situ formed and sintered silver nanoparticles was developed. At room temperature,the silver nanoparticles (Ag NPs) could not be generated in ECAs due to no reaction between silver nitrate and N,N-dimethyl-4-aminobenzaldehyde (DABA). However, during curing process, Ag NPs were immediately generated through reducing silver nitrate by DABA in absence of stabilizing agents. At the same time, the increased viscosity of epoxy due to the curing could prevent the agglomerates of Ag NPs. Morphology studies showed that most Ag NPs have been attached onto the surfaces of silver flakes due to the good affinity between them, resulting in more effectively interconnecting with silver flakes by the sintered Ag NPs. Thus, the lower bulk resistivity was obtained. On the other hand, DABA, containing a tertiary amine, can stabilize contact resistance of nano-ECAs by effectively preventing galvanic corrosion at the interface between nano-ECAs and Sn surfaces due to the fact that amines can strongly bond to a Sn surface.

Similar content being viewed by others

References

M. Inoue, H. Muta, T. Maekawa et al., J. Electron. Mater. 38, 430 (2009)

R.W. Zhang, K.S. Moon, W. Lin et al., J. Mater. Chem. 20, 2018 (2010)

Y. Oh, K.Y. Chun, E. Lee et al., J. Mater. Chem. 20, 3579 (2010)

H.J. Jiang, K.S. Moon, Y. Li et al., Chem. Mater. 18, 2969 (2006)

D. Wakuda, K.S. Kim, K. Suganuma, Scr. Mater. 59, 649 (2008)

J.G. Bai, T.G. Lei, J.N. Calata et al., J. Mater. Res. 22, 3494 (2007)

H.J. Jiang, K.S. Moon, J.X. Lu et al., J. Electron. Mater. 34, 1432 (2005)

D.I. Tee, M. Mariatti, A. Azizan et al., Compos. Sci. Technol. 67, 2584 (2007)

M. Zhang, M.Y. Efremov, F. Schiettekatte et al., Phys. Rev. B 62, 10548 (2000)

A.D. Albert, M.F. Becker, J.W. Keto et al., Acta Mater. 56, 1820 (2008)

Z. Zhang, G.Q. Lu, IEEE Trans. Electron. Pack. Manufact. 25, 279 (2002)

K.S. Chou, K.C. Huang, H.H. Lee, Nanotechnology 16, 779 (2005)

P. Zeng, S. Zajac, P.C. Clapp et al., Mater. Sci. Eng. A Struct. 252, 301 (1998)

Y.G. Sun, Y.N. Xia, Science 298, 2176 (2002)

D. Kim, S. Jeong, J. Moon, Nanotechnology 17, 4019 (2006)

M.N. Nadagouda, R.S. Varma, Cryst. Growth Des. 8, 291 (2008)

C.C. Luo, Y.H. Zhang, X.W. Zeng et al., J. Colloid Interface Sci. 288, 444 (2005)

M. Yamamoto, Y. Kashiwagi, M. Nakamoto, Langmuir 22, 8581 (2006)

M. Yamamoto, M. Nakamoto, J. Mater. Chem. 13, 2064 (2003)

M. Chen, Y.G. Feng, X. Wang et al., Langmuir 23, 5296 (2007)

Y.G. Sun, B. Mayers, T. Herricks et al., Nano Lett. 3, 955 (2003)

D.S. Seo, S.H. Park, J.K. Lee, Curr. Appl. Phys. 9, S72 (2009)

A. Kamyshny, M. Ben-Moshe, S. Aviezer et al., Macromol. Rapid Commun. 26, 281 (2005)

K. Cheng, M.H. Yang, W.W.W. Chiu et al., Macromol. Rapid Commun. 26, 247 (2005)

J. Perelaer, B.J. de Gans, U.S. Schubert, Adv. Mater. 18, 2101 (2006)

I. Reinhold, C.E. Hendriks, R. Eckardt et al., J. Mater. Chem. 19, 3384 (2009)

Y.Q. Fu, C. Shearwood, B. Xu et al., Nanotechnology 21, 115707 (2010)

S.H. Ko, H. Pan, C.P. Grigoropoulos et al., Nanotechnology 18, 345202 (2007)

M.L. Allen, M. Aronniemi, T. Mattila et al., Nanotechnology 19, 175201 (2008)

D. Wakuda, M. Hatamura, K. Suganuma, Chem. Phys. Lett. 441, 305 (2007)

H.H. Lee, K.S. Chou, Z.W. Shih, Int. J. Adhes. Adhes. 25, 437 (2005)

S. Pothukuchi, Y. Li, C.P. Wong, J. Appl. Polym. Sci. 93, 1531 (2004)

J.X. Lu, K.S. Moon, J.W. Xu et al., J. Mater. Chem. 16, 1543 (2006)

K.S. Moon, S. Liong, H.Y. Li et al., J. Electron. Mater. 33, 1381 (2004)

H.Y. Li, K.S. Moon, C.P. Wong, J. Electron. Mater. 33, 106 (2004)

Y.G. Sun, Y.D. Yin, B.T. Mayers et al., Chem. Mater. 14, 4736 (2002)

Y. Gao, P. Jiang, L. Song et al., J. Phys. D Appl. Phys. 38, 1061 (2005)

Y. Xia, Y.J. Xiong, B. Lim et al., Angew. Chem. Int. Ed. 48, 60 (2009)

G. Carotenuto, L. Nicolais, B. Martorana et al., in Metal-Polymer Nanocomposite Synthesis: Novel ex situ and in situ Approaches, ed. by L. Nicolais, G. Carotenuto (Wiley, NJ, 2005), p. 176

J.D. Rancourt, L.T. Taylor, Macromolecules 20, 790 (1987)

T. Sawada, S. Ando, Chem. Mater. 10, 3368 (1998)

B. Bittmann, F. Haupert, A.K. Schlarb, Ultrason. Sonochem. 18, 120 (2011)

M. Kurimoto, H. Okubo, K. Kato et al., IEEE Trans. Dielect. El. In. 17, 1268 (2010)

D.P. Chen, X.L. Qiao, X.L. Qiu et al., J. Mater. Sci.: Mater. Electron. 21, 486 (2010)

Y. Oh, D. Suh, Y. Kim et al., Nanotechnology 19, 495602 (2008)

Y. Li, K.S. Moon, A. Whitman et al., IEEE Trans. Comp. Pack. Technol. 29, 758 (2006)

H. Gao, L. Liu, Y.F. Luo, et al., J. Macromol. Sci. B: Phys. accepted, (2011)

Y. Li, C.P. Wong, Mater. Sci. Eng. R 51, 1 (2006)

D.Q. Lu, Q.K. Tong, C.P. Wong, IEEE Trans. Electron. Pack. Manufact. 22, 228 (1999)

S.S. Kim, K.S. Kim, S.J. Kim et al., 50th Electronic Materials Conference (Santa Barbara, CA, 2008)

D.Q. Lu, C.P. Wong, Int. J. Adhes. Adhes. 20, 189 (2000)

Acknowledgments

The authors would like to thank National Natural Science Foundation of China (contract grant numbers: 50608034 and 50873036) and “the Fundamental Research Funds for the Central Universities, SCUT” (2009ZM0306) for the financial support, and the College of Material Science and Engineering of South China University of Technology for the group in undertaking the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, H., Liu, L., Liu, K. et al. Preparation of highly conductive adhesives by in situ generated and sintered silver nanoparticles during curing process. J Mater Sci: Mater Electron 23, 22–30 (2012). https://doi.org/10.1007/s10854-011-0388-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0388-8