Abstract

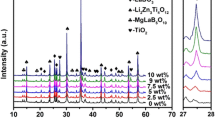

In this work, the LTCC composite ceramics containing α-alumina and quartz based on the binary system BaO–B2O3 were prepared by traditional solid-state preparation process at a sintering temperature of 900 °C. Sintering mechanism and physical properties of the LTCC composite ceramics are investigated and discussed in detail in terms of their mineral phase composition. The results indicate that, by the chemical combination of barium hydroxide octahydrate and an aqueous solution of boric acid, a barium borate phase can be formed form the binary system BaO–B2O3 and consequently supply a liquid sintering aid for the fabrication of LTCC composite ceramics at a sintering temperature of 900 °C. The introduction of α-alumina to the binary system BaO–B2O3 can improve the sintering behavior whereas the presence of quartz in the composite ceramics is important to achieve low permittivity. By the combination of α-alumina, quartz and BaO–B2O3 composition, the dense LTCC composite ceramics, which is characterized by excellent dielectric properties (permittivity: 3.56; 4.83; dielectric loss: 3 × 10−4; 4 × 10−4), can be fabricated availably.

Similar content being viewed by others

References

Y. Imanaka, Multilayered low temperature co-fired ceramics (LTCC) technology (Springer, New York, 2005), pp. 1–16

C. Jin, S. Lin, J.T. Wetzel, J. Electron. Mater. 30, 284 (2001)

R.D. Pendse, P. Zhou, Microeletron. Reliab. 301, 42 (2002)

M. Eberstein, T. Rabe, W.A. Schiller, Int. J. Appl. Ceram. Tchnol. 3, 428 (2006)

M.A. Vartanyan, E.S. Lukin, N.A. Popova, Glass. Ceram. 56, 1 (2008)

H.J. Kim, S.M. Nam, J. Ceram. Process Res. 10, 817 (2009)

Y.F. Zhang, S.L. Bai, M. Miao, Y.F. Jin, J. Eur. Ceram. Soc. 29, 1077 (2009)

C. Aksel, Mater. Lett. 57, 708 (2002)

I.J. Choi, Y.S. Cho, J. Electroceram. 23, 185 (2009)

E.M. Levin, H.F. McMurdie, F.P. Hall, Phase Diagrams for Ceramists (The American Ceramic Society, Columbus, 1956), p. 145

R.M. German, S. Farooq, C.M. Kipphut, Mater. Sci. Eng. A 105/106, 215 (1988)

M. Eberstein, C. Glitzky, M. Gemeinerrt, T. Rabe, W.A. Schiller, C. Modes, Int. J. Appl. Ceram. Tchnol. 3, 1 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, S., Zhang, S., Zhou, X. et al. Preparation of the LTCC composite ceramics with low permittivity. J Mater Sci: Mater Electron 22, 453–457 (2011). https://doi.org/10.1007/s10854-010-0158-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-010-0158-z