Abstract

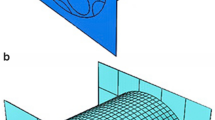

The metallic mesh in a wire-reinforced polymer could influence the thermo-mechanical behavior of the composite unusually due to thermal properties differences, but no research attention has been given to this potential problem. In this research, therefore, the viscoelastic and creep behaviors of steel wire and glass particulates-reinforced polymer composite were investigated experimentally. The wire was woven into diamond-shaped mesh as skeletal reinforcement in a glass particulates-filled polymer matrix and 40 × 12 × 4.8 mm composite specimens were produced through hand lay-up method. Three-point dynamic mechanical analysis was carried out at 2.5 Hz, 5.0 Hz, and 10 Hz frequencies. At 2.5 Hz, the steel wire caused the glass transition temperature, Tg, of the composites to decrease from 100.6 to 84.45 °C; the addition of glass particulates further decreased the Tg to 82.5 °C at 5% and 80.8 °C at 10% compositions and then increased it to 80.7 °C at 15% and 95.5 °C at 20% compositions. The pattern of change was the same at 5.0 Hz and 10.0 Hz frequencies of oscillation. The results suggest an interplay between the heat conductivity of the composite and the viscoelastic response. The steel wire reduced the instantaneous strain of the composite from about 0.07 to 0.005% and the steady-state strain rate from 7.4 × 10–5 s−1 to 3.97 × 10–6 s−1. The effect of steel wire on the viscoelastic behavior of the material dominates that of glass particulates. This research field can be developed further by correlating thermal inhomogeneity in the composite under fluctuating temperature with the nature of dynamic viscoelastic behavior. This research strategy is invaluable for materials development for pipelines and for parts that are subjected to dynamic loading and changing temperatures in service.

Similar content being viewed by others

Data and code availability

No data/code available.

References

Abdelal NR, Al-Saleh MH, Irshidat MR (2018) Utilizing vacuum bagging process to prepare carbon fiber/CNT-modified-epoxy composites with improved mechanical properties. Polym-Plast Technol Eng 57(3):175–184

Agarwal K, Kuchipudi SK, Girard B, Houser M (2018) Mechanical properties of fiber reinforced polymer composites: a comparative study of conventional and additive manufacturing methods. J Compos Mater 52(23):3173–3181

Truong GT, Tran HV, Choi K-K (2019) Tensile behavior of on- and off-axis carbon fiber reinforced polymer composites incorporating steel wire mesh. Mech Mater 137:103–131

Rajak DK, Pagar DD, Menezes PL, Linul E (2019) Fiber-reinforced polymer composites: manufacturing, properties, and applications. Polymers 11(10):1667

Dixit S, Goel R, Dubey A, Shivhare PR, Bhalavi T (2017) Natural fibre reinforced polymer composite materials—a review. Polym Renewable Resour 8(2):71–78

Kumar AD, Prasad KV, Rao RP (2016) Tensile and impact properties of jute/glass and jute/carbon fiber reinforced polypropylene. J Polym Compos 4(3):35–39

Croitoru EI, Oancea G, Constantin N (2017) Impact testing on composite panels of fiberglass, carbon and kevlar-carbon. Materiale plastice 54(4):700–707

Dan-asabe B, Yaro S, Yawas D (2018) Micro-structural and mechanical characterization of doum-palm leaves particulate reinforced PVC composite as piping materials. Alex Eng J 57(4):2929–2937

Joshi S, Drzal L, Mohanty A, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos A Appl Sci Manuf 35(3):371–376

Wang H, Memon H, Hassan AM, Miah MS, Ali MA (2019) Effect of jute fiber modification on mechanical properties of jute fiber composite. Materials 12(8):12–26

Kumre A, Rana R, Purohit R (2017) A review on mechanical property of sisal glass fiber reinforced polymer composites. Mater Today: Proc 4(2):3466–3476

Cao D (2023) Strengthening the interphase of thermoplastic sandwich composites by interleaving carbon nanotube yarns. Mater Today Commun 36:606–655

Cao D, Bouzolin D, Lu H, Griffith DT (2023) Bending and shear improvements in 3D-printed core sandwich composites through modification of resin uptake in the skin/core interphase region. Compos B Eng 264:110–122

Cao D (2023) Enhanced buckling strength of the thin-walled continuous carbon fiber–reinforced thermoplastic composite through dual coaxial nozzles material extrusion process. Int J Adv Manuf Technol 128(3–4):1305–1315

Shi J, Zhong S, Nie X, Shi J, Zheng J (2021) Study on steel wire reinforced thermoplastic pipes under combined internal pressure and bending moment at various temperatures. Thin-Walled Struct 169:180–181

Shang P, Qu Y, Zhao J (2013) Parameters optimization of steel wire reinforced thermoplastics composite pipe. Adv Mater Res 690–693:399–403

El-Gebeily M, Khulief Y, Ghneim A (2016) A multiresolution approach for damage detection in fiber-reinforced polymer pipe systems. Adv Mech Eng 8(9):1–11

Patnaik A, Satapathy A, Mahapatra S, Dash R (2008) Parametric optimization erosion wear of polyester-GF-alumina hybrid composites using the taguchi method. J Reinf Plast Compos 27(10):1039–1058

Suresha B, Chandramohan G, Samapthkumaran P, Seetharamu S (2007) Three-body abrasive wear behaviour of carbon and glass fiber reinforced epoxy composites. Mater Sci Eng, A 443(1–2):285–291

Srinivas K, Bhagyashekar M (2014) Wear behaviour of epoxy hybrid particulate composites. Procedia Eng 97:488–494

Zheng J, Lu Y, Xiang L, Lin X, Zhu Y, Xu P, Chen D, He X, Shao T (2008) Experimental investigation on mechanical properties of plastic pipes reinforced by cross helically steel wires. J Press Vessel Technol 130(2):21–28

Smith KE, Parks SS, Hyjek MA, Downey SE, Gall K (2009) The effect of the glass transition temperature on the toughness of photopolymerizable (meth)acrylate networks under physiological conditions. Polymer 50(21):5112–5123

Serenko OA, Roldughin VI, Askadskii AA, Serkova ES, Strashnov PV, Shifrina ZB (2017) The effect of size and concentration of nanoparticles on the glass transition temperature of polymer nanocomposites. Royal Soc Chem Adv 7(79):50113–50120

Smith TL (1965) Deformation and failure of plastics and elastomers. Polym Eng Sci 5(4):270–279

Boparai KS, Singh R (2018) Thermoplastic composites for fused deposition modeling filament: challenges and applications. In: Reference module in materials science and materials engineering, vol 36. Elsevier, pp 774–784

Robertson CG, Lin C, Rackaitis M, Roland C (2008) Influence of particle size and polymer- filler coupling on viscoelastic glass transition of particle-reinforced polymers. Macromolecules 41(7):2727–2731

Zhai S, Zhang P, Xian Y, Zeng J, Shi B (2018) Effective thermal conductivity of polymer composites: theoretical models and simulation models. Int J Heat Mass Transf 117:358–374

Callister WD, Rethwisch DG (2016) Materials science and engineering: an introduction. John Wiley & Sons, NJ

Dan-asabe B (2018) Thermo-mechanical characterization of banana particulate reinforced PVC composite as piping material. J King Saud Univ—Eng Sci 30(4):296–304

Deng Y, Yi P, Peng L, Lai X, Lin Z (2015) Flow behavior of polymers during the roll-to-roll hot embossing process. J Micromech Microeng 25(6):640–650

Li Y, Guo Y, Hu H, Wei Q (2009) A critical assessment of high-temperature dynamic mechanical testing of metals. Int J Impact Eng 36(2):177–184

Wang X, Gong L-X, Tang L-C, Peng K, Pei Y-B, Zhao L, Wu L-B, Jiang J-X (2015) Temperature dependence of creep and recovery behaviors of polymer composites filled with chemically reduced graphene oxide. Compos A Appl Sci Manuf 69:288–298

Kumlutas D, Tavman IH (2006) A numerical and experimental study on thermal conductivity of particle filled polymer composites. J Thermoplast Compos Mater 19(4):441–455

Naga KS, Jayakumar V, Madhu S (2019) Evaluation of mechanical characterization of CFRP reinforced stainless steel (SS304) wire mesh polymer composite. IOP Conf Ser: Mater Sci Eng 574(1):120–134

Cui Y, Campbell J, Burley M, Patel M, Hunt K, Clyne T (2020) Effects of temperature and filler content on the creep behaviour of a polyurethane rubber. Mech Mater 148:103–111

Karthik D, Baheti V, Novotná J, Samková A, Pulíček R, Venkataraman M, Srb P, Voleská K, Wang Y, Militký J (2020) Effect of particulate fillers on creep behaviour of epoxy composites. Mater Today: Proc 31:S217–S220

Kelly P (2013) Solid mechanics part I: an introduction to solid mechanics. The University of Auckland, Auckland

Eftekhari M, Fatemi A (2016) On the strengthening effect of increasing cycling frequency on fatigue behavior of some polymers and their composites: experiments and modeling. Int J Fatigue 87:153–166

ASTM D4065, Standard test method for glass transition temperature of polymers, ASTM International, Philadelphia, (2017)

ASTM D2990, Standard test method for flexural creep of polymers, ASTM International, Philadelphia, (2017)

ASTM D790, Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials, ASTM, Chicago, (2017)

Obada D, Kuburi L, Dauda M, Umaru S, Dodoo AD, Balogun M, Iliyasu I, Iorpenda M (2018) Effect of variation in frequencies on the viscoelastic properties of coir and coconut husk powder reinforced composites. J King Saud Univ—Eng Sci 32:148–157

Senden D, Van DJ, Govaert L (2010) Strain hardening and its relation to bauschinger effects in oriented polymers. J Polym Sci, Part B: Polym Phys 48(13):1483–1494

Khan KA, Muliana AH, Rajagopal K, Wineman A (2018) On viscoelastic beams undergoing cyclic loading: determining the onset of structural instabilities. Int J Non-Linear Mech 99:40–50

Wineman A, Min JH (2000) Viscoelastic hinge formation in beams. Acta Mech 140(3–4):183–205

Rasana N, Jayanarayanan K, Deeraj B, Joseph K (2019) The thermal degradation and dynamic mechanical properties modeling of MWCNT/glass fiber multiscale filler reinforced polypropylene composites. Compos Sci Technol 169:249–259

Samal SK, Mohanty S, Nayak SK (2009) Polypropylene’bamboo/glass fiber hybrid composites: fabrication and analysis of mechanical, morphological, thermal, and dynamic mechanical behavior. J Reinf Plast Compos 28(22):2729–2747

Sakthivel K (2020) Effect of of Glass/kevalar Fibre/aluminium 2200 wire mesh reinforced composite. Ilkogretim Online 19(1):1098–1113

Abu-Abdeen M (2012) Static and dynamic mechanical properties of poly (vinyl chloride) loaded with aluminum oxide nanopowder. Mater Des 33:523–528

Jabbar A, Militký J, Madhukar KB, Rwawiire S, Nawab Y, Baheti V (2016) Modeling and analysis of the creep behavior of jute/green epoxy composites incorporated with chemically treated pulverized nano/micro jute fibers. Ind Crops Prod 84:230–240

Saba N, Jawaid M (2018) A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J Ind Eng Chem 67:1–11

Gunes IS, Cao F, Jana SC (2008) Effect of thermal expansion on shape memory behavior of polyurethane and its nanocomposites. J Polym Sci, Part B: Polym Phys 46(14):1437–1449

Flaifel MH, Ahmad SH, Hassan A, Bahri S, Tarawneh MA, Yu L-J (2013) Thermal conductivity and dynamic mechanical analysis of NiZn ferrite nanoparticles filled thermoplastic natural rubber nanocomposite. Compos B Eng 52:334–339

Kontou E (2005) Tensile creep behavior of unidirectional glass-fiber polymer composites. Polym Compos 26(3):287–292

Eftekhari M, Fatemi A (2016) Creep behavior and modeling of neat, talc-filled, and short glass fiber reinforced thermoplastics. Compos B Eng 97:68–83

Kausch HH, Beguelin P, Fischer M (2000) Failure of particulate reinforced polymers. In: Mechanics of composite materials, vol 36, pp 177–184

Homkhiew C, Ratanawilai T, Thongruang W (2014) Time–temperature and stress dependent behaviors of composites made from recycled polypropylene and rubberwood flour. Constr Build Mater 66:98–104

Li M, Li D, Wang L-J, Adhikari B (2015) Creep behavior of starch-based nanocomposite films with cellulose nanofibrils. Carbohyd Polym 117:957–963

Acknowledgements

Dr. David O. Obada, Dr. Abdulhakeem Bello, Mr. Aminu L. Yahaya, Petroleum Technology Development Fund (PTDF), Nigeria

Author information

Authors and Affiliations

Contributions

Engr. P. S. Noma contributed to conception (lead), experimental design and execution (lead), manuscript composition (lead). Prof. M Dauda contributed to conception (supporting), experimental design and execution (supporting). Dr. B. Dan-asabe contributed to experimental design and execution (supporting), manuscript composition (supporting). Engr. Sam O. Jolaiya contributed to experimental design and execution (supporting) and manuscript composition (supporting).

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no conflicts of interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Noma, P.S., Dauda, M., Dan-asabe, B. et al. Viscoelastic response of steel wire and particulate-reinforced polymer under dynamic and creep loading. J Mater Sci 59, 7733–7752 (2024). https://doi.org/10.1007/s10853-024-09660-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09660-y