Abstract

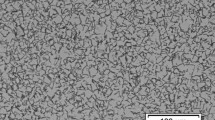

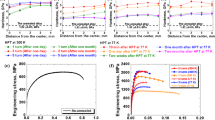

This study investigates the correlation between coercivity (Hc), grain size (d), and dislocation density in the Permimphy alloy (Fe–80%Ni–6%Mo). The samples used in this study were subjected to varying levels of applied strain through processing by high-pressure torsion. The microstructure and the magnetic coercivity were analyzed using a scanning electron microscope, electron backscatter diffraction and vibrating sample magnetometry. The grain size of the samples varied from 30 to 190 nm. This study demonstrated a strong correlation between Hc and microhardness when d > 3 µm. The results show that the coercivity of the Permimphy alloy follows an inverse V-shape with respect to grain size. The coercivity of the samples decreased despite increasing the dislocation density and the hardness when d < 3 µm. This phenomenon is attributed to the ferromagnetic exchange interaction across multiple grains and leads to the alignment of magnetic moments.

Similar content being viewed by others

Data availability

Some data included in this work are available upon request by contact with the corresponding author.

References

Czichos H, Saito T, Smith LR (2006) Springer handbook of materials measurement methods. Springer, Berlin

Ouyang G, Chen X, Liang Y et al (2019) Review of Fe-6.5 wt%Si high silicon steel—a promising soft magnetic material for sub-kHz application. J Magn Magn Mater 481:234–250. https://doi.org/10.1016/j.jmmm.2019.02.089

Gutfleisch O, Willard MA, Brück E et al (2011) Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv Mater 23:821–842. https://doi.org/10.1002/adma.201002180

Waeckerlé T, Demier A, Godard F, Fraisse H (2020) Evolution and recent developments of 80%Ni permalloys. J Magn Magn Mater 505:166635. https://doi.org/10.1016/j.jmmm.2020.166635

PERMIMPHY is a 80% Nickel soft magnetic alloy. In: Aperam. https://www.aperam.com/product/permimphy-80-nickel/. Accessed 3 Apr 2023

Han L, Maccari F, Souza Filho IR et al (2022) A mechanically strong and ductile soft magnet with extremely low coercivity. Nature 608:310–316. https://doi.org/10.1038/s41586-022-04935-3

Nabi B, Helbert A-L, Brisset F et al (2013) Effect of recrystallization and degree of order on the magnetic and mechanical properties of soft magnetic FeCo–2V alloy. Mater Sci Eng A 578:215–221. https://doi.org/10.1016/j.msea.2013.04.066

Nabi B, Helbert A-L, Brisset F et al (2014) Effect of long range order on mechanical properties of partially recrystallized Fe49Co–2V alloy. Mater Sci Eng A 592:70–76. https://doi.org/10.1016/j.msea.2013.10.093

Herzer G (1989) Grain structure and magnetism of nanocrystalline ferromagnets. IEEE Trans Magn 25:3327–3329. https://doi.org/10.1109/20.42292

Herzer G (1990) Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans Magn 26:1397–1402. https://doi.org/10.1109/20.104389

Herzer G (1997) Chapter 3 Nanocrystalline soft magnetic alloys. In: Handbook of Magnetic Materials. Elsevier, pp 415–462

Herzer G (2013) Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater 61:718–734. https://doi.org/10.1016/j.actamat.2012.10.040

Suzuki K, Ito N, Garitaonandia JS et al (2008) Local random magnetocrystalline and macroscopic induced anisotropies in magnetic nanostructures. J Non-Cryst Solids 354:5089–5092. https://doi.org/10.1016/j.jnoncrysol.2008.06.118

Pfeifer F, Radeloff C (1980) Soft magnetic Ni–Fe and Co–Fe alloys—some physical and metallurgical aspects. J Magn Magn Mater 19:190–207. https://doi.org/10.1016/0304-8853(80)90592-2

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979. https://doi.org/10.1016/j.pmatsci.2008.03.002

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater 47:579–583. https://doi.org/10.1016/S1359-6454(98)00365-6

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981. https://doi.org/10.1016/j.pmatsci.2006.02.003

Zhilyaev AP, Kim B-K, Nurislamova GV et al (2002) Orientation imaging microscopy of ultrafine-grained nickel. Scr Mater 46:575–580. https://doi.org/10.1016/S1359-6462(02)00018-0

Zhilyaev AP, Nurislamova GV, Kim B-K et al (2003) Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion. Acta Mater 51:753–765. https://doi.org/10.1016/S1359-6454(02)00466-4

Azzeddine H, Bradai D, Baudin T, Langdon TG (2022) Texture evolution in high-pressure torsion processing. Prog Mater Sci 125:100886. https://doi.org/10.1016/j.pmatsci.2021.100886

Wongsa-Ngam J, Kawasaki M, Langdon TG (2013) A comparison of microstructures and mechanical properties in a Cu–Zr alloy processed using different SPD techniques. J Mater Sci 48:4653–4660. https://doi.org/10.1007/s10853-012-7072-0

Figueiredo RB, Pereira PHR, Aguilar MTP et al (2012) Using finite element modeling to examine the temperature distribution in quasi-constrained high-pressure torsion. Acta Mater 60:3190–3198. https://doi.org/10.1016/j.actamat.2012.02.027

Ateba Betanda Y, Helbert A-L, Brisset F et al (2014) Measurement of stored energy in Fe–48%Ni alloys strongly cold-rolled using three approaches: neutron diffraction, Dillamore and KAM approaches. Mater Sci Eng A 614:193–198. https://doi.org/10.1016/j.msea.2014.07.037

Azzeddine H, Tirsatine K, Baudin T et al (2017) On the stored energy evolution after accumulative roll-bonding of invar alloy. Mater Chem Phys 201:408–415. https://doi.org/10.1016/j.matchemphys.2017.08.063

Bate PS, Knutsen RD, Brough I, Humphreys FJ (2005) The characterization of low-angle boundaries by EBSD. J Microsc 220:36–46. https://doi.org/10.1111/j.1365-2818.2005.01513.x

Pippan R, Scheriau S, Taylor A et al (2010) Saturation of fragmentation during severe plastic deformation. Annu Rev Mater Res 40:319–343. https://doi.org/10.1146/annurev-matsci-070909-104445

Rathmayr GB, Pippan R (2011) Influence of impurities and deformation temperature on the saturation microstructure and ductility of HPT-deformed nickel. Acta Mater 59:7228–7240

Renk O, Pippan R (2019) Saturation of grain refinement during severe plastic deformation of single phase materials: reconsiderations, current status and open questions. Mater Trans 60:1270–1282

Tsuji N, Kamikawa N, Li BL (2007) Grain size saturation during severe plastic deformation. In: Materials science forum. Trans Tech Publ, pp 2837–2842

Yu T, Hansen N, Huang X (2011) Recovery by triple junction motion in aluminium deformed to ultrahigh strains. Proc R Soc Math Phys Eng Sci 467:3039–3065. https://doi.org/10.1098/rspa.2011.0097

Yu T, Hansen N, Huang X, Godfrey A (2014) Observation of a new mechanism balancing hardening and softening in metals. Mater Res Lett 2:160–165

Tsuji N (2008) Formation mechanisms of ultrafine grained structures in severe plastic deformation of metallic materials. J Iron Steel Inst Jpn 94:582–589

Humphreys FJ, Hatherly M (2012) Recrystallization and related annealing phenomena. Elsevier

Kawasaki M (2014) Different models of hardness evolution in ultrafine-grained materials processed by high-pressure torsion. J Mater Sci 49:18–34. https://doi.org/10.1007/s10853-013-7687-9

Lee SW, Horita Z (2010) Annealing behavior of FeNi alloy processed by high-pressure torsion. Mater Sci Forum 667–669:313–318. https://doi.org/10.4028/www.scientific.net/MSF.667-669.313

Tirsatine K, Azzeddine H, Huang Y et al (2018) An EBSD analysis of Fe-36%Ni alloy processed by HPT at ambient and a warm temperature. J Alloys Compd 753:46–53. https://doi.org/10.1016/j.jallcom.2018.04.194

Tirsatine K, Azzeddine H, Baudin T et al (2014) Texture and microstructure evolution of Fe–Ni alloy after accumulative roll bonding. J Alloys Compd 610:352–360. https://doi.org/10.1016/j.jallcom.2014.04.173

Bonnot E, Helbert A-L, Brisset F, Baudin T (2013) Microstructure and texture evolution during the ultra grain refinement of the Armco iron deformed by accumulative roll bonding (ARB). Mater Sci Eng A 561:60–66. https://doi.org/10.1016/j.msea.2012.11.017

Boudekhani S, Azzeddine H, Tirsatine K et al (2018) Microstructure, texture, and mechanical properties of Ni-W alloy after accumulative roll bonding. J Mater Eng Perform 27:5561–5570. https://doi.org/10.1007/s11665-018-3628-8

Cullity BD, Graham CD (2011) Introduction to magnetic materials. Wiley

Hosokawa A, Ohtsuka H, Li T et al (2014) Micostructure and magnetic properties in nanostructured Fe and Fe-based intermetallics produced by high-pressure torsion. Mater Trans 55:1286–1291. https://doi.org/10.2320/matertrans.M2014119

Xiang Z, Sun Q, Wang S (2022) Effect of dislocation pattern on the magnetic domain structure of pure polycrystalline Ni. J Mater Res Technol 17:1896–1900. https://doi.org/10.1016/j.jmrt.2022.01.107

Lo CCH, Kinser E, Jiles DC (2003) Modeling the interrelating effects of plastic deformation and stress on magnetic properties of materials. J Appl Phys 93:6626–6628. https://doi.org/10.1063/1.1557356

Dabou O, Bensouilah A, Baudin T et al (2023) Evolution of the texture, microstructure, and magnetic properties of a Permimphy alloy after accumulative roll bonding and aging. J Mater Sci. https://doi.org/10.1007/s10853-023-08994-3

Gabold H, Luan Z, Paul N et al (2018) Structural and magnetic properties of cobalt iron disulfide (CoxFe1−xS2) nanocrystals. Sci Rep 8:4835. https://doi.org/10.1038/s41598-018-22996-1

Acknowledgements

Two of the authors were supported by the European Research Council under Grant Agreement No. 267464-SPDMETALS (YH and TGL).

Author information

Authors and Affiliations

Contributions

Oussama Dabou (M.Sc.) contributed to investigation, validation, writing, and visualization. Thierry Baudin (Dr.) contributed to methodology, review and editing, visualization. François Brisset (Dr.) contributed to methodology and investigation. Thierry Waeckerlé (Dr.) and Yanick Ateba Betanda (Dr.) contributed to methodology and review. Yi Huang (Prof.) contributed to methodology, review and editing. Djamel Bradai (Prof.) and Anne-Laure Helbert (Prof.) contributed to conceptualization, writing, original draft, review and editing, visualization and supervision. Terence G. Langdon (Prof.) contributed to review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial or personal interests concerning the work reported in this manuscript to the best of their knowledge.

Ethical approval

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dabou, O., Baudin, T., Brisset, F. et al. Correlation between microstructure, magnetic properties and mechanical behavior of the Permimphy alloy after high-pressure torsion. J Mater Sci 59, 5968–5980 (2024). https://doi.org/10.1007/s10853-024-09490-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09490-y