Abstract

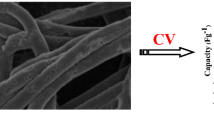

Electrospinning is a simple and effective technique for preparing carbon nanofibers. However, carbon nanofiber materials have some drawbacks, such as low specific surface area, small pore size, and low porosity, which can affect the electrochemical performance of supercapacitors. This article proposes a preparation method for a multi-level porous structure for thick electrodes. Sponge-like nanofibers are formed through electrospinning by adding a certain amount of PMMA to the polyacrylonitrile mixed spinning solution after doping with heteroatoms. After reverse hanging pre-oxidation and carbonization, a hierarchical porous, highly conductive, and flexible carbon nanofiber sponge is obtained. After testing, at a current density of 0.25 A g−1, its specific capacitance reached 207 F g−1. As the power density increased from 250 W kg−1 to 3997.89 W kg−1, the energy density changed from 28.73 W h kg−1 to 8.44 W h kg−1, demonstrating that the porous active carbon nanofiber sponge electrode has a significant energy storage advantage.

Graphical abstract

Similar content being viewed by others

References

Li Q et al (2020) Flexible solar yarns with 15.7% power conversion efficiency, based on electrospun perovskite composite nanofibers. Solar Rrl 4(9):2000269

Zhang Y et al (2021) Recent advances and challenges of electrode materials for flexible supercapacitors. Coord Chem Rev 438:213910

Li Z, Liu X, Wang X, Wang H, Ren J, Wang R (2022) Electrophoretic deposition of Ti3C2Tx MXene nanosheet N-carbon cloth as binder-free supercapacitor electrode material. J Alloys Compsd 927:166934

Fang Y et al (2020) Porous and free-standing Ti3C2T -RGO film with ultrahigh gravimetric capacitance for supercapacitors. Chin Chem Lett 31(4):1004–1008

Wang Y, Wu X, Han Y, Li T (2021) Flexible supercapacitor: overview and outlooks. J Energy Storage 42:103053

Wang G, Jiang N, Zhang Z, Wang G, Cheng K (2022) Free-standing 3D porous energy hydrogels enabled by ion-induced gelation strategy for High-performance supercapacitors. Appl Surf Sci 604:154636

Ran F, Wang T, Chen S, Liu Y, Shao L (2020) Constructing expanded ion transport channels in flexible MXene film for pseudocapacitive energy storage. Appl Surf Sci 511:145627

Zhang T et al (2022) In situ ice template approach to fabricate Ag modified 3D Ti3C2Tx film electrode for supercapacitors. Electrochimica Acta 422:140461

Heme HN, Alif MSN, Rahat SMSM, Shuchi SB (2021) Recent progress in polyaniline composites for high capacity energy storage: a review. J Energy Storage 42:103018

Kuang Y, Chen C, Kirsch D, Hu L (2019) Thick electrode batteries: principles, opportunities, and challenges. Adv Energy Mater 9(33):1901457

Wang F et al (2021) Phosphorus-doped thick carbon electrode for high-energy density and long-life supercapacitors. Chem Eng J 414:128767

Lei E et al (2021) High-performance supercapacitor device with ultrathick electrodes fabricated from all-cellulose-based carbon aerogel. Energy Fuels 35(9):8295–8302

Choi SY, Han EM, Park KH (2019) Porosity control of electrospun PAN/PMMA nanofiber webs. Mol Cryst Liq Cryst 688(1):68–74

Abeykoon NC, Bonso JS, Ferraris JP (2015) Supercapacitor performance of carbon nanofiber electrodes derived from immiscible PAN/PMMA polymer blends. RSC Adv 5(26):19865–19873

Gui C, Zhang Y, Jin R, Song Y, Li R, Xing Y (2021) Fabrication of hierarchically porous carbon nanofibers from immiscible PAN/PVDF polymer blends as electrode materials. Fibers and Polymers 22(4):972–980

Yu W, Xin B, Lu Z (2022) Ultralight and extra-soft fiber sponge with “marshmallow- shape” fabricated by layer-by-layer self-assembly electrospinning method. Compos Commun 32:101164

Ali N, Hussain T, Wang X, Yu J, Ding B (2023) Nickle oxide nanoparticles incorporated flexible and porous carbon nanofiber-based adsorbents for CO2 capture. Compos Commun 40:101604

Zhang B, Weng X, Yu X, Wang Z, Liu X, He T (2023) Opening tubular structure polyimide/polyvinyl chloride based carbon nanofibers for supercapacitor. Mater Sci Eng B 288:116169

Li X et al (2017) A non-woven network of porous nitrogen-doping carbon nanofibers as a binder-free electrode for supercapacitors. Electrochim Acta 230:445–453

An GH, Koo BR, Ahn HJ (2016) Activated mesoporous carbon nanofibers fabricated using water etching-assisted templating for high-performance electrochemical capacitors. Phys Chem Chem Phys 18(9):6587–6594

Lu H et al (2020) Tailoring hierarchically porous nitrogen-, sulfur-codoped carbon for high-performance supercapacitors and oxygen reduction. Small 16(17):e1906584

Zhang X et al (2023) Slit needleless electrospun heteroatoms-doped hollow porous carbon nanofibers for solid-state flexible supercapacitors. J Alloys Compd 943:169188

Zhang X et al (2022) Design of hierarchical porous carbon nanofibrous membrane for better electrochemical performance in solid-state flexible supercapacitors. J Alloys Compd 920:165983

Wei K et al (2017) Nitrogen- and oxygen-containing porous ultrafine carbon nanofiber: a highly flexible electrode material for supercapacitor. J Mater Sci Technol 33(5):424–431

Acknowledgements

This project was funded by the National Natural Science Foundation of China (Grant No. 11702169) and Class III Peak Discipline of Shanghai—Materials Science and Engineering (High-Energy Beam Intelligent Processing and Green Manufacturing) (Project No.19YF1417900).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors certify that none of their known financial conflicts of interest or close personal ties might have appeared to have influenced the research presented in this study.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, Y., Newton, M.A.A., Xin, B. et al. Preparation of hierarchical porous polyacrylonitrile-based fiber sponges and electrochemical performance study. J Mater Sci 58, 17326–17339 (2023). https://doi.org/10.1007/s10853-023-09124-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09124-9