Abstract

In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) epilayers with a fixed In content of \(\textit{x}\) = 0.145 were grown on GaSb(100) substrates using liquid-phase epitaxy (LPE). The lattice mismatch between the quaternary epilayers and substrates was analyzed for different As contents (\(\textit{y}\)) by X-ray \(\omega\)-2\(\theta\). Epilayers with As content between \(\textit{y}\) = 0.120 and \(\textit{y}\) = 0.124 exhibited a positive lattice mismatch, leading to compressive strain. These samples showed a high crystalline quality and flat surfaces, as confirmed by high-resolution X-ray diffraction (HR-XRD) and atomic force microscopy (AFM). Quaternary alloys with As content between \(\textit{y}\) = 0.133 and \(\textit{y}\) = 0.141 displayed a negative lattice mismatch, resulting in tensile strain. Structural defects in these samples were evidenced by HR-XRD and on AFM micrographs. Raman measurements also revealed that lateral strain has a direct impact on the intensities of the LO-like, phonon–plasmon and disorder-activated longitudinal acoustic modes. For all In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) films, photoluminescence (PL) spectra showed a bound exciton (BE) transition, with additional features observed in samples under tensile strain, indicating the involvement of native defect centers and donor–acceptor pairs. This study provides new insights into the effect of lateral strain on the crystalline and surface quality, and optical properties of quaternary alloys, relevant for novel optoelectronic applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The quaternary alloy InGaAsSb is an innovative semiconductor material belonging to the III–V family of compounds, used for infrared optoelectronic applications in fields, including biological sensing, space monitoring and renewable energy production [1,2,3,4,5,6]. Its wide operating range covers from the near infrared (1.8 \(\mu\)m) up to the mid-infrared (4.8 \(\mu\)m), which can be controlled by adjusting the In and As contents [7]. This characteristic, combined with its direct band gap and zinc-blende structure, makes it a versatile material for use in a range of devices including thermophotovoltaic systems [8, 9], laser heterostructures [10, 11], and fast-sensing instruments, positioning it as a viable alternative to other commercial infrared materials such as HgCdTe [12].

The most effective methods for fabricating In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\)-based structures are epitaxial growth methodologies [13, 14]. Among the various available techniques, liquid-phase epitaxy (LPE) has demonstrated the potential to efficiently develop high crystalline quality quaternary layers at the lowest cost [15, 16]. However, growing the quaternary alloy in the liquid phase requires careful consideration of certain conditions to ensure the crystallinity of the epilayers. For instance, high In content alloys (\(x > 0.23\) [17]) exhibit a miscibility gap that can only be overcome by increasing growth temperature. Nonetheless, this results in the formation of defects within the crystalline structure [18]. Another key aspect of the growth process relies on the matching conditions of the alloy with a substrate. In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) has been extensively grown on GaSb substrates for various applications [19,20,21]. Researchers have reported two solid solution regions as a function of In content in which the alloy is lattice matched to the GaSb substrate, namely \(0< x < 0.28\) and \(x > 0.7\) [22]. Furthermore, successful growth of In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) on GaSb substrates is achievable through precise control of the As content using the following approximation: \(y \approx 0.1 + 0.9x\) [23]. The attainment of lattice matching condition is governed by Vegard’s law [24] for the In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) quaternary alloy: a\(_{\text {InGaAsSb}}\)=xya\(_{\text {InAs}}\)+x(1-y)a\(_{\text {InSb}}\)+(1-x)ya\(_{\text {GaAs}}\)+(1-x)(1-y)a\(_{\text {GaSb}}\) [25], where \(\textit{x}\) represents the In content, \(\textit{y}\) denotes the As content and a is the lattice constant of either the binaries or quaternary compounds. For achieving lattice matching, where \(\Delta\)a/a = 0 and a\(_{\text {InGaAsSb}}\) = a\(_{\text {GaSb}}\) = 6.0959 Å, we solve for \(\textit{y}\) (As content) for any given \(\textit{x}\); the numerical values for the corresponding lattice parameters are shown in Table 1.

which represents the lattice match condition for As content as a function of any In content [25].

The hetero-epitaxial growth of In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) layers results in a relative lattice mismatch between the epilayer and the substrate, which can impact the morphology of the epilayer. Joullié et al. [26] have reported various phenomena which occur in the LPE technique when growing In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) epilayers on GaSb substrates as a function of the lattice mismatch sign, defined as \(\Delta a/a = (a_{\text {epilayer}} - a_{\text {substrate}})/a_{\text {substrate}}\). It was observed that heterostructures with a positive lattice mismatch sign (\(\Delta a/a > 0\)) and an absolute value of approximately \(10^{-3}\) exhibit a uniform and flat surface, whereas those with a negative sign (\(\Delta a/a < 0\)) display cracks on the surface and an increased etch pit density. The structural defects in In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\)/GaSb heterostructures are generated by the lattice strain and the subsequent relaxation of the upper quaternary growing layers [27]. Lateral coherent strain on an epilayer grown on a (100) zinc-blende substrate is defined by \(\varepsilon _{||} = \varepsilon _{yy} = \varepsilon _{zz} = (a_{\text {substrate}} - a_{\text {epilayer}})/a_{\text {epilayer}}\) [28]; considering that the epilayer thickness is much smaller than the substrate thickness, the latter remains unstrained [29]. The sign of lateral strain value indicates the type of strain applied to the epilayer, with positive sign (\(a_{\text {substrate}} - a_{\text {epilayer}} > 0\), \(\Delta a/a < 0\)) meaning tension and negative sign (\(a_{\text {substrate}} - a_{\text {epilayer}} < 0\), \(\Delta a/a > 0\)) meaning compression. Tensile strain can disrupt uniform step growth and lead to a different growth mechanism [30, 31], whereas epilayers with a lattice mismatch positive sign tend to exhibit a smoother surface [32].

Lateral strain can affect the material’s properties, such as electronic or optical behavior [33, 34]. In semiconductor devices, such as transistors and integrated circuits, lateral strain can be intentionally introduced to modify the electrical properties and enhance device performance, for example, increasing electron mobility [35]. In the case of In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) thin films, lateral strain offers a range of benefits for infrared applications by modifying the material’s characteristics. As it is possible to grow them onto substrates with slightly different lattice constants, this strain results in controlled deformations across the crystal structure [36]. Some of the key advantages of this development are: bandgap engineering, enabling precise tailoring of the material’s response to different infrared wavelengths, optimal designing of infrared detectors, photodetectors, and imaging sensors operating optimally within specific infrared ranges [37, 38]. The ability to control lateral strain provides a powerful tool for designing advanced infrared light sources with tailored emission characteristics. Moreover, controlled lateral strain enhances the performance of In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\)-based electronic devices by improving carrier mobility. Modifying the crystal lattice results in faster and more efficient components, a crucial aspect for high-speed communication and data processing applications, significantly boosting overall system efficiency. In order to improve the crystalline quality of In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) for optoelectronic devices, a series of studies must be conducted to evaluate and comprehend the behavior of the alloy under variations of its composition. This work involved growing a series of In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) epitaxial layers on GaSb (100) substrates using the LPE technique. The In content was fixed at 0.145, while the As content varied on each film. The lattice mismatch was analyzed using high-resolution X-ray diffraction (HR-XRD) to evaluate its impact on structural defects formation. The crystalline quality also was studied by Raman spectroscopy. The lateral strain and elastic strain energy were carefully studied in order to identify their effect on the crystalline and surface quality. Optical properties were also investigated by the low-temperature photoluminescence (PL) technique.

Experimental details

Crystalline films growth

In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) epitaxial films were grown using the LPE technique in a horizontal furnace system under a palladium-purified H\(_{2}\) flux. The reactor used was a high-purity graphite boat. GaSb(100) wafers were cleaved to produce multiple substrates, which were thoroughly chemically cleaned to remove organic agents and the oxide layer from the surface. The In content was fixed at \(x = 0.145\). In, Ga and Sb of 6N purity were used, and a GaAs wafer was used as a precursor for As. In order to prevent the substrates dissolution by the melt, a slight supercooling ramp was applied (\(0.3 \,^{\circ }\textrm{C}\)/min) in all epilayers. Eight epitaxial layers were grown with different As contents at a growth temperature of \(529 \,^{\circ }\textrm{C}\) for 1 min.

Structural characterization

High-resolution X-ray diffraction (HR-XRD) technique was used to observe the structural characteristics of the epilayers. Measurements were taken using a PANalytical MRD X-ray diffractometer with a Cu target K\(\alpha _1\) emission line as the X-ray source. To obtain maximum resolution, a two-bounce hybrid monochromator and a three-bounce germanium (200) analyzer were employed. Raman scattering spectra were acquired using a laser confocal Raman spectrometer (NT-MDT, Integra Spectra). The measurements were taken at room temperature, employing the backscattering geometry and utilizing the 532 nm wavelength under normal incidence. The laser beam was focused to a 6 mm-diameter spot on the sample surface using a 100 mm aperture microscope objective.

Optical characterization

The optical properties of the In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) epilayers were studied using photoluminescence (PL) spectroscopy at low temperature (22 K). The measurements were taken by a standard experimental setup that included an Acton monochromator and a closed-circuit helium (He) refrigerator. Photoexcitation was provided by a chopped 488 nm line argon (Ar) laser. The PL signals from the samples were detected using a PbS infrared detector operating at room temperature and a lock-in amplifier.

Morphological characterization

The surface morphology of the In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\) films was analyzed using atomic force microscopy (AFM) with a thermomicroscope. The microscope was equipped with a 633 nm laser wavelength and operated in the tapping mode using an etched Si cantilever.

Results and discussion

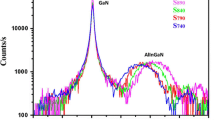

Structural properties of the In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\) epilayers with different As contents were analyzed employing HR-XRD. Figure 1 displays the diffractograms for samples A and H. The \(\omega\)-2\(\theta\) measurements revealed a peak at 2\(\theta\) = \(60.72^\circ\) with a full width at half maximum (FWHM) of 56.50” corresponding to the GaSb (400) diffraction. Another peak observed in the diffractograms is attributed to the (400) plane of the quaternary alloy, with As content of \(y = 0.120\) for sample A (peak at 2\(\theta\) = \(60.69^\circ\), at the left of GaSb (400) with a FWHM of 92.88”), and \(y = 0.141\) for sample H (peak at 2\(\theta\) = \(60.80^\circ\), at the right of GaSb (400) with a FWHM of 101.36”).

Figure 2 illustrates the influence of the As content variation on the crystalline structure through the diffractograms of the In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\) (400) planes. The change in the quaternary peak position (indicated by *) ranges from \(2\theta\) = 60.69\(^\circ\) (sample A) to \(2\theta\) = 60.80\(^\circ\) (sample H). The shift in the quaternary (400) peak from left to right with respect to the GaSb (400) peak (\(2\theta\) = 60.72\(^\circ\)) is attributed to the As content. Also, we observed that the FWHM of each quaternary alloy changes with arsenic content as follows: Samples A, B, C and D presented a FWHM of 92.88”, 92.15”, 90.35” and 91.07”, respectively, while samples E, F, G and H presented a FWHM of 87.90”, 93.74”, 101.00” and 101.36”, respectively. This indicates that the crystalline quality decreases with the arsenic content and at the same time the FWHM increases. The quaternary alloy’s lattice parameter was calculated using 2\(\theta\) peak position [25]. It is important to have in consideration that for achieving an exact lattice-matched heterostructure (\(\Delta a/a = 0\)) for In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\), As content must be \(y = 0.126\). For quaternary epilayers with lower As content (\(y<\) 0.126), the lattice mismatch is positive (\(\Delta a/a > 0\)), leading to higher lattice parameters than the substrate (\(a_{\text {GaSb}}\) = 6.0959 \(\mathring{\text {A}}\)) and diffraction peaks to the left. For those with higher As content (\(y>\) 0.126), lattice parameters are smaller than the substrate and results in a negative lattice mismatch (\(\Delta a/a < 0\)), causing the peak’s shift to the right.

HR-XRD diffractograms of In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\) epilayers with different As contents. The variation of the In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) (400) reflection (represented by * symbol) goes from \(y = 0.120\) (positive lattice mismatch) to \(y = 0.141\) (for negative lattice mismatch).

As mentioned above, the quaternary crystal lattice experiences coherent strain at the interface generated by the lattice mismatch between the grown epilayer and the substrate. The lateral strain of the In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\)/GaSb heterostructures was estimated using \(\varepsilon _{||}\) strain equation \(\varepsilon _{||} = \varepsilon _{yy} = \varepsilon _{zz} = (a_{\text {substrate}} - a_{\text {epilayer}})/a_{\text {epilayer}}\). Figure 3 shows the increase of the lateral strain with the As content (y). The dashed horizontal line denotes the exact lattice matching condition \(\left(\varepsilon _{||} = (a_{\text {substrate}} - a_{\text {epilayer}})/a_{\text {epilayer}} = 0\right)\) and divides the strain of the epilayers into two distinct regions. Compressive strain (\(\varepsilon _{||} < 0\)) for \(y < 0.126\) (blue circles) and tensile strain (\(\varepsilon _{||} > 0\)) for \(y > 0.126\) (red squares).

To understand the effect of the compositional variation of the In\(_{x}\)Ga\(_{1-x}\)As\(_{y}\)Sb\(_{1-y}\) alloy on its elastic strain energy, the latter was calculated using the elastic potential energy expression given by [35]:

where \(C_{11}\), \(C_{12}\) and \(C_{44}\) are the elastic stiffness coefficients of the In\(_{x}\)Ga\(_{1-x}\)As\(_{y}\)Sb\(_{1-y}\) obtained under virtual crystal (VCA); a VCA crystal is considered as having an average effective crystal potential which is evaluated for a lattice constant given by Vegard’s law. In general, any property of a quaternary alloy can be linearly interpolated between the properties of their binary constituents, suggesting that the chemical bond of atoms in an alloy smoothly changes between the values of the end-point compounds. Such assumption is the premise of the VCA. The VCA gives a good description if there is not a crystallographic phase change with the composition, and effects arising from chemical disorders are not included. In this sense, the elastic stiffness coefficients are given by C=C(x, y)=\(xyC_{\text {InAs}}\)+x(1-y)\(C_{\text {InSb}}\)+(1-x)\(yC_{\text {GaAs}}\)+(1-x)(1-y)\(C_{\text {GaSb}}\). The values employed for the calculation are presented in Table 1. In our calculations, we considered that the interface between the In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\) epilayer and GaSb (100) substrate (In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\)/GaSb(100)), the In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) is under biaxial deformation in the direction parallel to the surface due to difference in lattice constants and undergoes tetragonal distortion. Also, we assumed that the substrate is infinitely thick; hence, there is no in-plane shear strain in the epilayer growth on GaSb (100) substrate. We have calculated the corresponding strain matrix employing the formulation of the reference [29], resulting for the (100) substrate, \(\varepsilon _{yy}\)=\(\varepsilon _{zz}\)=\(\varepsilon _{\parallel },\varepsilon _{xx}\)=\(\varepsilon _{\perp }\), and the shear strain components \(\varepsilon _{yz}\)=\(\varepsilon _{yx}\)=\(\varepsilon _{xz}\)=0. The lateral and vertical strains of In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) epilayer are related by the following expressions:

and

Figure 4a displays the elastic strain energy of In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) quaternary alloys on GaSb (100) for all combinations of In and As contents. The lowest strain energy is observed in the diagonal region (purple area), where the lattice parameters of the quaternary alloy and the substrate are closer. Meanwhile, the highest energy (red area) occurs for an In content of \(x = 0\) and an As content of \(y = 1\), resulting in the GaAs binary compound. The GaAs lattice parameter is the smallest of the four binary compounds that constitute the quaternary alloy, leading to a larger tensile strain due to the high lattice mismatch with the GaSb substrate. The open circles indicate the strain energy of the grown samples, all of them remaining in the purple area.

Figure 4b shows the dependence of the elastic strain energy on As content in the range of \(0.103 \le y \le 0.150\). Samples A, B, C and D (blue circles) are in the compressive strain energy region, while samples E, F, G and H are in the tensile strain energy region (red circles). Lower elastic strain energy is associated with better crystalline quality and a lattice mismatch closer to 0. Therefore, samples A, B, C and D (under compressive strain) should have better structural properties.

Elastic strain energies of the In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) quaternary alloys on GaSb(100) were calculated for a all combinations of the In (x) and As (y) contents and b for x = 0.145 as a function of the As content. The elastic strain energies for samples with compressive strain are represented by blue circles and for samples with tensile strain by red squares.

Figure 5 shows the Raman spectra of samples A and B under compressive strain and the Raman spectra of samples F and G under tensile strain. All spectra were normalized concerning the total area to quantify the relative variation between the intensities of the resonance peaks. Two main peaks were identified as the LO-Like mode of In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) quaternary alloy at 237.5 cm\(^{-1}\) and the phonon–plasmon coupling (PH–PL) localized at 221.6 cm\(^{-1}\). The peak localized at 178.7 cm\(^{-1}\) was identified as the forbidden TO-InSb and is caused by the disruption of the crystalline order, while the broadband located at 130 cm\(^{-1}\) is originated by disorder-activated longitudinal acoustic phonons (DALA), which are linked to residual strain disorder [40,41,42]. In Fig. 5a, it is observed that sample A exhibits a lower intensity in the LO-like mode and the coupled PH–PL mode compared to sample B. This is because sample A is subjected to a higher compressive strain than sample B, affecting phonon and phonon–plasmon resonances. In contrast, the TO-InSb and DALA modes are more noticeable in sample A than in sample B. These variations show that as compressive strain in the quaternary alloy increases, the intensities associated with the crystalline disorder increase, and consequently, the resonances of the allowed optical phonon modes are attenuated. In the spectra of Fig. 5b, the behavior of intensity variation reemerges concerning the degree of tensile strain. This is evidenced by the fact that sample G, which has a higher content of As, displays an attenuation in the LO-like and PH–PL coupled modes compared to sample F, although the variation in the intensity of the DALA mode is less notable.

To establish a correlation between residual strain and crystalline quality of the In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) quaternary alloy, the FWHM and integrated intensities of the Raman modes identified in spectra of Fig. 5 were quantified. Figure 6a presents the behavior of the FWHM of HR-XRD diffraction peak (data points as spheres) and the FWHM of the LO-Like mode (data points as triangles) as a function of As content. The vertical dashed line indicates the As content to perfect lattice match between the quaternary alloy and the GaSb substrate. To the left of this dashed line, the FWHM quantified for both techniques is presented for films subjected to compressive strain, while on the right side of this dashed line, the FWHM for films under tensile strain is shown. In quaternary films under compressive strain, the variation of As content has a limited effect on the FWHM of HR-XRD diffraction peak, while it exerts a more pronounced influence on the dispersion of the phononic longitudinal optical mode, as reflected in this graph. On the other hand, for samples subjected to tensile strain, the variation in As content induces a larger change in the FWHM of HR-XRD diffraction peak compared to samples under compressive strain. This suggests that tensile strain has a larger influence than compressive strain on the crystallization kinetics of the quaternary alloy. The dependency of the FWHM of the LO-like of In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) exhibits similar behavior, correlating with both the As content and the crystalline strain in the samples. Figure 6b presents the normalized integrated intensities of the Raman modes identified in Fig. 5 as a function of the As content. The dashed vertical line indicates the As content for the perfect lattice match between quaternary alloy and GaSb substrate. The integrated intensities of the LO-like mode and the PH–PL mode are indicated by upward and downward open triangles, respectively, while the intensities of the TO-InSb the DALA modes are represented by star and sphere symbols, respectively. For quaternary films subjected to compressive strain, the intensities of the LO-like and PH–PL modes decrease with decreasing As concentration, while the intensity of modes attributed to crystalline disorder (DALA and TO-InSb) increases with reduced As content. This behavior correlates with the previously presented results, as in this growth regime, a reduction in the As content for quaternary thin films implies greater compressive stress, inducing a higher degree of crystalline disorder. Similarly, in films subjected to tensile strain, higher As content corresponds to increased residual strain, leading to a more detrimental growth that results in decreased intensities of the LO-like and coupled PH–PL modes, and a slight increase in the TO-InSb and DALA modes of the quaternary alloy.

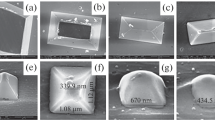

To analyze the influence of tensile and compressive strain on the growth of films, the surface morphology of the films was observed using atomic force microscopy (AFM). Micrographs of \(5 \times 5\) \(\mu\)m\(^2\) for samples A, D, G and H are presented in Fig. 7. Notably, the surface morphology of samples A and D, which are under compressive strain (\(\Delta a/a > 0\)), is flat and smoother with a root-mean-square (rms) roughness of 1.748 and 1.954 nm, respectively. In contrast, samples G and H, which experienced tensile stress (\(\Delta a/a < 0\)), showed a rough surface with an rms roughness of 6.109 and 7.208 nm, respectively. These samples exhibit the formation of three-dimensional (3D) structures (step-like corrugations) induced by the differences in lattice constants by LPE [43]. The surface uniformity observed in samples A and D under compressive strain is attributed to the lower As content of the epilayers in comparison with samples G and H under tensile strain. In agreement with previous results, the samples under tensile strain presented higher elastic strain energy and higher roughness than the samples under compressive strain; additionally, the samples under compressive strain presented the lowest FWHM of HR-XRD and the higher-quality crystalline. As previously mentioned, the surface morphology of LPE grown films is influenced by the lattice mismatch. This effect is observed during the initial stages of growth when a skin layer is formed at the liquid–solid interface of the melt. The skin layer experiences either compressive or tensile stress, depending on the sign of the lattice mismatch. In addition to this, it is essential to consider the potential dissolution of the substrate by the melt, which can be mitigated applying a supercooling ramp in the growth process. In this study, all samples were grown using a supercooling ramp of \(0.3 \,^{\circ }\textrm{C}\)/min. Films that experienced compressive stress exhibited the flattest surfaces due to the prevention of substrate dissolution achieved via supercooling. Conversely, films that experienced tensile stress developed rougher surfaces as the skin layer under tensile stress formed microcracks, which could cause substrate dissolution, even with the presence of a supercooling ramp [26]. During this initial stage of growth, the formation of step-like corrugations was inevitable through the formation of terraces due to this liquid solution incorporation and the subsequent bunching of ad-atoms on the edges of these structures [43], which explains the rougher surface observed in samples G and H.

The optical properties of the grown samples were studied using the PL technique at 22 K. Figure 8a illustrates the spectrum of sample A (under compressive strain), and figure 8b shows the spectrum of sample H (under tensile strain). Gaussian fitting of both spectra reveals a radiative contribution labeled as BE, which is associated with a bound exciton state. The FWHM of the BE transitions in all samples is \(\approx\)10 meV, and this value is consistent with the one presented in quaternary alloys with similar composition grown by LPE [25]. However, there is a second peak in the spectrum of sample H (with a higher As content), labeled as DAP, which is associated with the radiative recombination involving donor–acceptor pairs (DAP) from the native acceptor defect centers. The native defects, mainly vacancies of Ga (V\(_{\text {Ga}}\)), antisites of Ga in Sb (Ga\(_{\text {Sb}}\)) and complexes of both defects (V\(_{\text {Ga}}\)–Ga\(_{\text {Sb}}\)), are in agreement with acceptor defects found in the GaSb [44].

The BE transition for epilayers A and H is at 635.6 and 637.4 meV, respectively. The DAP transition present only in the spectrum of the sample H (\(\Delta a/a < 0\)), is at 596.4 meV. The binding energy of the native acceptor defects in sample H can be determined by subtracting the band gap energy from the DAP transition energy, resulting in a value of 41 meV, consistent with the value of 38 meV determined in the In\(_x\)Ga\(_{1-x}\)As\(_y\)Sb\(_{1-y}\) alloy by Iyer et al. [44]. It is remarkable that the DAP transition was not observed in the spectra of sample A. This result suggests that center defects decrease for samples under lower elastic strain energy, which has to be considered for optoelectronic applications. The band gap energy of the epilayers was estimated from the BE values by adding 4 meV to each one of them (this corresponds to the binding energy of the bonded exciton) [25].

Conclusions

We grew In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\)/GaSb heterostructures using LPE technique. The In content was fixed at x = 0.145, while the As content was varied in all quaternary epilayers. Our results showed that varying the As content produced both lateral compressive and tensile strain. Quaternary alloys with As content between y = 0.120 and y = 0.124 exhibited a positive lattice mismatch between the films grown and the GaSb substrate, leading to a compressive strain. These alloys presented a high crystalline quality, as evidenced by the FWHM of HR-XRD between 90.35 and 92.88”. Additionally, they showed a high surface quality with a root-mean-square (rms) roughness between 1.748 and 1.954 nm measured by AFM. Conversely, quaternary alloys with As content between y = 0.133 and y = 0.141 displayed a negative lattice mismatch, resulting in lateral tensile strain. For these quaternary alloys, the surface morphology exhibited the formation of 3D step-like corrugation. Moreover, HR-XRD measurements indicated a FWHM ranging from 87.99 to 101.36”. These samples also evidenced a higher rms roughness (between 6.109 and 7.208 nm) compared to the films under compressive strain. Besides, we calculated the elastic strain energy for In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) alloys and found that alloys grown under compressive strain had lower elastic energy, which is associated with better crystalline quality. Raman spectra also were studied for the quaternary alloys. All samples exhibited the allowed LO-like and coupled phonon–plasmon modes generated by long-range crystalline order. However, the observed TO-InSb and DALA modes are originated from Raman scattering selection rule breaking, which is induced and correlated with the residual lattice strain and crystalline disorder. PL shows a BE transition for all quaternary alloys. For films with tensile strain, a second transition was found, originated from native defect centers involving donor–acceptor (DAP) pairs. PL study confirmed that samples with compressive strain have higher structural quality. By considering the lattice mismatch sign, the generated lateral strain, the elastic stress energy and the miscibility gap of the material, we were able to grow high-quality liquid-phase epitaxial layers of In\(_{0.145}\)Ga\(_{0.855}\)As\(_{y}\)Sb\(_{1-y}\) on GaSb substrates that can be applied to the design of various optoelectronic devices for the infrared spectrum.

References

Wootten MB, Tan J, Chien YJ, Olesberg JT, Prineas JP (2014) Broadband 2.4 \(\mu\)m superluminescent GaInAsSb/AlGaAsSb quantum well diodes for optical sensing of biomolecules. Semicond Sci Technol 29(11):115014

Zhang XL, Huang AB, Lou YY, Li X, Cui M, Wang Y (2019) Thermophotovoltaic energy conversion with GaSb lattice-matched Ga\(_{1-x}\)In\(_x\)As\(_y\)Sb\(_{1-y}\) diodes. IEEE Trans Electron Devices 66(2):901–907

Magri R, Zunger A, Kroemer H (2005) Evolution of the band-gap and band-edge energies of the lattice-matched GaInAsSb/GaSb and GaInAsSb/InAs Alloys as a Function of Composition. J Appl Phys 98(4):043701

Abedin MN, Refaat TF, Joshi RP, Sulima OV, Mauk MG, Singh UN (2003) Characterization and analysis of InGaAsSb detectors. Infrared Technol Appl XXIX 5074:332–342

Caneau C, Srivastava AK, Dentai AG, Zyskind JL, Pollack MA (1985) Room-temperature GaInAsSb/AlGaAsSb DH injection lasers at 2.2 \(\mu\)m. Electron Lett 18(21):815–817

Peng X, Zhang B, Li G, Zou J, Zhu Z, Cai Z, Jiang W (2011) Simulation of temperature-dependent material parameters and device performances for GaInAsSb thermophotovoltaic cell. Infrared Phys Technol 54(6):454–459

Kalinina KV, Mikhailova MP, Zhurtanov BE, Stoyanov ND, Yakovlev YP (2013) Superlinear electroluminescence in GaSb-based heterostructures with high potential barriers. Semicond 47(1):73–80

Lu Q, Beanland R, Montesdeoca D, Carrington PJ, Marshall A, Krier A (2019) Low Bandgap GaInAsSb thermophotovoltaic cells on gaas substrate with advanced metamorphic buffer layer. Sol Energy Mater Sol Cells 191:406–412

Lou YY, Zhang XL, Huang AB, Wang Y (2017) Enhanced thermal radiation conversion in a GaSb/GaInAsSb tandem thermophotovoltaic cell. Sol Energy Mater Sol Cells 172:124–132

Morosini MBZ, Herrera-Perez JL, Loural MSS, Von Zuben AAG, Silveira ACF, Patel NB (1993) Low-threshold GaInAsSb/GaAlAsSb double-heterostructure lasers grown by LPE. IEEE J Quantum Electron 29(6):2103–2108

Liang R, Kipshidze G, Hosoda T, Shterengas L, Belenky G (2014) 3.3–3.4-\(\mu\)m diode lasers based on triple-layer gainassb quantum wells. IEEE Photon Technol Lett 26(7):664–666

Abedin MN, Refaat TF, Sulima OV, Singh UN (2006) Recent development of Sb-based phototransistors in the 0.9-to 2.2-\(\mu\)m wavelength range for applications to laser remote sensing. Int J High Speed Electron Syst 16(02):567–582

Wesolowski M, Strupinski W, Motyka M, Sek G, Dumiszewska E, Caban P, Pierscinska D (2011) Study of MOCVD growth of InGaAsSb/AlGaAsSb/GaSb heterostructures using two different aluminium precursors TMAl and DMEAAl. Opto-Electron Rev 19(2):140–144

Zhang YG, Li AZ, Zheng YL, Lin C, Jian GZ (2001) MBE Grown 2.0 \(\mu\)m InGaAsSb/AlGaAsSb MQW ridge waveguide laser diodes. J Cryst Growth 227:582–585

Craig AP, Jain M, Wicks G, Golding T, Hossain K, McEwan K, Marshall ARJ (2015) Short-wave infrared barriode detectors using InGaAsSb absorption material lattice matched to GaSb. Appl Phys Lett 106(20):201103

González-Morales MA, Cruz-Bueno JJ, Villa-Martínez G, Ramírez-López M, Flores-Ramírez D, Rodríguez-Fragoso P, Mendoza-Álvarez JG (2022) Importance of liquid phase epitaxy on achieving near-lattice-matched growth of In\(_{0.145}\)Ga\(_{0.855}\)As\(_{0.132}\)Sb\(_{0.868}\) layers on GaSb (100) substrates. Superficies y Vacío 35:220601

DeWinter JC, Pollack MA, Srivastava AK, Zyskind JL (1985) Liquid phase epitaxial Ga\(_{1-x}\)In\(_x\)As\(_y\)Sb\(_{1-y}\) lattice-matched to (100) GaSb over the 1.71 to 2.33 \(\mu\)m Wavelength Range. J Electron Mater 14(6):729–747

Capper P, Mauk M (eds) (2007) Liquid phase epitaxy of electronic optical and optoelectronic materials. John Wiley & Sons, Chichester, England

Piotrowski TT, Piotrowska A, Kaminska E, Piskorski M, Papis Polakowska E, Golaszewska K, Nowak Z (2001) Design and fabrication of GaSb/InGaAsSb/AlGaAsSb mid-IR photodetectors. Photodetectors 4413:339–344

Voronina TI, Zhurtanov BE, Lagunova TS, Mikhailova MP, Moiseev KD, Rozov AE, Yakovlev YP (2001) Type II heterojunctions in an InGaAsSb/GaSb system: magnetotransport properties. Semicond 35(3):331–337

Shvarts MZ, Andreev VM, Khvostikov VP, Larionov VR, Rumyantsev VD, Sorokina SV, Shvarts MZ, Vlasov AS (1997) Tandem GaSb/InGaAsSb thermophotovoltaic cells for space applications. In: Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference-1997, pp. 935–938

Mikhailova MP, Titkov AN (1994) Type II heterojunctions in the GaInAsSb/GaSb system. Semicond Sci Technol 9(7):1279

Mauk MG (2002) New High-Performance GaSb-based thermophotovoltaic devices. Final Report. Technical Report DOE/ER/86057-1, AstroPower, Inc., Newark, Delaware

Nahory R, Pollack M, Johnston W Jr, Barns R (1974) Band gap versus composition and demonstration of Vegard’s law for In1- x Ga x As y P1- y lattice matched to InP. Appl Phys Lett 33(7):659–661

Casallas-Moreno YL, Villa-Martínez G, Ramírez-López M, Rodríguez-Fragoso P, Gómez-Herrera ML, Pérez-González M, Escobosa-Echavarría A, Tomás SA, Herrera-Pérez JL, Mendoza-Álvarez JG (2019) Growth mechanism and physical properties of the type-I In\(_{0.145}\)Ga\(_{0.855}\)As\(_y\)Sb\(_{1-y}\)/GaSb alloys with low As content for near infrared applications. J Alloys Compd 808(5):151690–11516909

Joullié A, Hua FJ, Karouta F, Mani H (1986) LPE growth of GaInAsSb/GaSb system: the importance of the sign of the lattice mismatch. J Cryst Growth 75(2):309–318

Springholz G, Frank N, Bauer G (1995) The origin of surface roughening in lattice-mismatched Frank van der Merwe type heteroepitaxy. Thin solid films 267(1–2):15–23

Schlenker D, Miyamoto T, Chen Z, Kawaguchi M, Kondo T, Gouardes E, Iga K (2000) Inclusion of strain effect in miscibility gap calculations for III-V semiconductors. Jpn J Appl Phys 39(10R):5751

Pohl UW (2020) Epitaxy of Semiconductors. Springer, Cham, Switzerland

Tu Y, Tersoff J (2004) Origin of apparent critical thickness for island formation in heteroepitaxy. Phys Rev Lett 93(21):216101

Yoon M, Lee HN, Hong W, Christen HM, Zhang Z, Suo Z (2007) Dynamics of step bunching in heteroepitaxial growth on vicinal substrates. Phys Rev Lett 99(5):055503

Liu D, Cho SJ, Seo JH, Kim K, Kim M, Shi J, Ma Z (2018) Lattice-mismatched semiconductor heterostructures. arXiv preprint arXiv:1812.10225

Tanner DSP, Caro MA, Schulz S, O’Reilly EP (2019) Fully analytic valence force field model for the elastic and inner elastic properties of diamond and zincblende crystal. arXiv:1908.11245vl1908.11245vl

Dolabella S, Borzì A, Dommann A, Neels A (2022) Lattice strain and defects analysis in nanostructured semiconductor materials and devices by high-resolution X-ray diffraction: theoretical and practical aspects. Small Methods 6(2):2100932

Dommann A, Neels A (2009) The role of strain in new semiconductor devices. Adv Eng Mater 11(4):27–277

Sayed IEH, Carlin CZ, Hagar BG, Colter PC, Bedair S (2016) Strain-balanced InGaAsSb/GaInP multiple quantum well solar cells with a tunable bandgap (1.65–1.82 ev). IEEE J Photovolt 6(4):997–1003

Wook Shin H, Jun Lee S, Gun Kim D, Bae M-H, Heo J, Jin Choi K, Jun Choi W, Choe J-W, Cheol Shin J (2015) Short-wavelength infrared photodetector on Si employing strain-induced growth of very tall InAs nanowire arrays. Sci Rep 5(1):10764

Ren A, Yuan L, Xu H, Wu J, Wang Z (2019) Recent progress of III-V quantum dot infrared photodetectors on silicon. J Mater Chem C 7(46):14441–14453

Adachi S (2009) Properties of Semiconductor Alloys: group-IV. III-V and II-VI Semiconductors. Wiley, Chichester, England

Zhanget YW (2014) Molecular beam epitaxial growth of AlSb/InAsSb heterostructures. Appl Surf Sci 313:479–483

Smiri B (2020) Optical and structural properties of In-rich InxGa1-xAs epitaxial layers on (100) InP for SWIR detectors. Mater Sci Eng B Solid State Mater Adv Technol 262:114769

Cheetham KJ, Carrington PJ, Krier A, Patel I, Martin FL (2012) Raman spectroscopy of pentanary GaInAsSbP narrow gap alloys lattice matched to InAs and GaSb. Semicond Sci Technol 27:1

Tirado-Mejía L, Ramírez JG, Gómez ME, Ariza-Calderón H (2006) Surface morphology analysis of GaInAsSb films grown by liquid phase epitaxy. Braz J Phys 36:1070–1073

Iyer S, Hegde S, Abul-Fadl A, Bajaj K, Mitchell W (1993) Growth and photoluminescence of GaSb and Ga1-xInxAsySb1-y grown on GaSb substrates by liquid-phase electroepitaxy. Phys Rev B 48:8521

Acknowledgements

The authors would like to express their gratitude to Rogelio Jaime Fragoso Soriano from Cinvestav Zacatenco for his valuable technical support with AFM. Y.L. Casallas-Moreno, M.A. González-Morales, J.J. Cruz-Bueno and G. Villa-Martínez thank CONAHCYT for financial support. The authors are also grateful for the financing of SIP-IPN projects.

Funding

The funding was provide by Consejo Nacional de Humanidades, Ciencia y Tecnología.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Kevin Jones.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

González-Morales, M.A., Villa-Martínez, G., Cruz-Bueno, J.J. et al. Determination of lateral strain in InGaAsSb alloys and its effect on structural and optical properties. J Mater Sci 58, 16172–16183 (2023). https://doi.org/10.1007/s10853-023-08991-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08991-6