Abstract

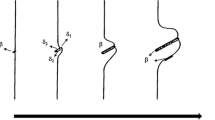

The particle size distribution and solidification of dispersed Cu-rich particles within the core region of stable core shell microstructures in drop tube processed metastable Cu-50 at. % Co alloy was studied with a view of understanding the evolution and growth of these microstructures. Microstructural evidence indicates that the formation of the core shell microstructures is highly influenced by nucleation and growth phenomenon. Coalescence propelled by collision is favoured in smaller droplets owing to their higher cooling rates and subsequent higher degree of undercooling to facilitate the liquid phase separation process. Weaker Marangoni motion impeded the further convergence of the Cu-rich particles within the core region.

Graphical abstract

Similar content being viewed by others

Data and code availability

Not applicable.

References

Zhou ZM, Gao J, Li F, Zhang YK, Wang YP, Kolbe M (2009) On the metastable miscibility gap in liquid Cu–Cr alloys. J Mater Sci 44:3793–3799. https://doi.org/10.1007/s10853-009-3511-y

Munitz A, Abbaschian R (1996) Microstructure of Cu-Co alloys solidified at various supercoolings. Metall Mater Trans A 27:4049–4059. https://doi.org/10.1007/BF02595654

Ratke L, Korekt G, Brück S, Schmidt-Hohagen F, Kasperovich G, Köhler M (2009) Phase equilibria and phase separation processes in immiscible alloys, in: 2nd Sino Ger Symp

Herlach DM, Holland-Moritz D, Galenko P (2006) Metastable solids from undercooled melts, Elsevier

Nakagawa Y (1958) Liquid immiscibility in copper-iron and copper-cobalt systems in the supercooled state. Acta Metall 6:704–711. https://doi.org/10.1016/0001-6160(58)90061-0

Yamauchi IN, Ueno M, Shimaoka IO (1998) Undercooling in Co—Cu alloys and its effect on solidification structure. J Mater Sci 33:371–378. https://doi.org/10.1023/A:1004319829612.

Munitz A, Abbaschian R (1991) Two-melt separation in supercooled Cu-Co alloys solidifying in a drop-tube. J Mater Sci 26:6458–6466. https://doi.org/10.1007/BF00551897

Zhang Y, Wu Z, Wang M, Yang C, Wilde G (2014) Effect of undercooling on particle size distribution in phase separated Cu75Co25-xMx (M = Ni, Fe) alloys with low M content. J Alloys Compd 596:55–57. https://doi.org/10.1016/j.jallcom.2014.01.182

Potard C (1982) Structures of immiscible A1-In alloys solidified under microgravity conditions. Acta Astronaut 9:245–254. https://doi.org/10.1016/0094-5765(82)90027-3

Liu Y, Guo J, Su Y, Ding H, Jia J (2001) Microstructure of rapidly solidified Al-In immiscible alloy. Trans Nonferrous Met Soc China 11:84–89

Moore K, Zhang D, Cantor B (1990) Solidification of Pb particles embedded in Al. Acta Metall Mater 38:1327–1342. https://doi.org/10.1016/0956-7151(90)90205-U

Luo X, Chen L (2008) Investigation of microgravity effect on solidification of medium-low-melting-point alloy by drop tube experiment. Sci China Ser E Technol Sci 51:1370–1379. https://doi.org/10.1007/s11431-008-0128-3

Wang Y, Song X, Sun Z, Zhou X, Guo J (2007) The solidification of CuCr alloys under various cooling rates. Mater Sci Pol 25:199–207

Sun Z, Wang Y, Guo J (2006) Liquid phase separation of Cu-Cr alloys during rapid cooling. Trans Nonferrous Met Soc China 16:998–1002. https://doi.org/10.1016/S1003-6326(06)60367-1

Fihey JL, Nguyen-Duy P, Roberge R (1976) On the solidification microstructure of copper-rich niobium alloys. J Mater Sci 11:2307–2311. https://doi.org/10.1007/BF00752095

Chen YZ, Liu F, Yang GC, Xu XQ, Zhou YH (2007) Rapid solidification of bulk undercooled hypoperitectic Fe–Cu alloy. J Alloys Compd 427:L1–L5. https://doi.org/10.1016/J.JALLCOM.2006.03.012

He J, Zhao J (2005) Behavior of Fe-rich phase during rapid solidification of Cu–Fe hypoperitectic alloy. Mater Sci Eng A 404:85–90. https://doi.org/10.1016/J.MSEA.2005.05.045

Cao CD, Wei B, Herlach DM (2002) Disperse structures of undercooled Co-40 wt% Cu droplets processed in drop tube. J Mater Sci Lett 21:341–343. https://doi.org/10.1023/A:1017913029777

Zhang Y, Gao J, Yasuda H, Kolbe M, Wilde G (2014) Particle size distribution and composition in phase-separated Cu 75Co25 alloys under various magnetic fields. Scr Mater 82:5–8. https://doi.org/10.1016/j.scriptamat.2014.03.003

Zhao JZ, Ratke L, Feuerbacher B (1998) Microstructure evolution of immiscible alloys during cooling through the miscibility gap. Model Simul Mater Sci Eng 6:123–139

Kolbe M, Gao JR (2005) Liquid phase separation of Co-Cu alloys in the metastable miscibility gap. Mater Sci Eng A 413–414:509–513. https://doi.org/10.1016/j.msea.2005.08.170

Zhang YK, Gao J, Nagamatsu D, Fukuda T, Yasuda H, Kolbe M, He JC (2008) Reduced droplet coarsening in electromagnetically levitated and phase-separated Cu-Co alloys by imposition of a static magnetic field. Scr Mater 59:1002–1005. https://doi.org/10.1016/j.scriptamat.2008.07.005

Zhang Y, Gao J, Wei L, Kolbe M, Volkmann T, Herlach D (2011) Novel insight into microstructural evolution of phase-separated Cu–Co alloys under influence of forced convection. J Mater Sci 46:6603–6608

Jegede OE, Cochrane RF, Mullis AM (2018) Metastable monotectic phase separation in Co–Cu alloys. J Mater Sci 53:11749–11764. https://doi.org/10.1007/s10853-018-2417-y

Acknowledgements

Oluwatoyin Jegede is a commonwealth scholar, sponsored by the UK government.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest related to this work.

Ethical approval

Not applicable.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jegede, O.E., Mullis, A.M. & Cochrane, R.F. Size distribution and solidification of Cu-rich dispersed particles in the core region of stable core shell microstructures of metastable alloy. J Mater Sci 58, 4213–4222 (2023). https://doi.org/10.1007/s10853-023-08287-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08287-9