Abstract

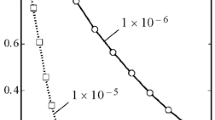

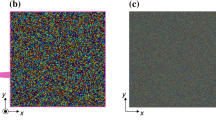

The mean-field theory proposed by Humphreys is widely used to predict or interpret abnormal grain growth induced by nonuniform grain boundary properties. Based on this theory, the abnormal growth conditions of a specific grain can be expressed as a function of only three parameters: the size ratio, boundary energy ratio, and mobility ratio between the specific grain and its surrounding matrix grains. However, quantitative and systematic validation of this theory is not yet reported neither in experiments nor simulations. In this study, to elucidate the validity of the mean-field theory, we perform large-scale phase-field simulations for two-dimensional and three-dimensional abnormal grain growth. The multi-phase-field numerical model and parallel graphics processing unit computing are employed, which enables the accurate analyses of abnormal growth in large-scale systems with several hundreds of thousands of grains while accounting for the nonuniformity in grain boundary properties. Systematic simulations are performed while varying the size ratio, boundary energy ratio, and mobility ratio between the specific grain and matrix grains. The simulated results and theoretical predictions on the abnormal grain growth behaviors, i.e., whether or not the abnormal growth occurs and the maximum size that can be reached by an abnormally growing grain, are compared in detail. The large-scale multi-phase-field simulations reveal for the first time the agreement between the mean-field theory and numerical simulation quantitatively, demonstrating that the mean-field theory is a versatile means for describing abnormal grain growth.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data supporting the findings of this study are available upon reasonable request.

References

Humphreys FJ, Hatherly M (2004) Recrystallisation and related annealing phenomena, 2nd edn. Elsevier Ltd., Oxford

Atkinson HV (1988) Overview no. 65: Theories of normal grain growth in pure single phase systems. Acta Metall 36:469–491. https://doi.org/10.1016/0001-6160(88)90079-X

Rollett AD (2004) Crystallographic texture change during grain growth. JOM 56:63–68. https://doi.org/10.1007/s11837-004-0075-9

Lee HY, Kim JS, Kim DY (2000) Fabrication of BaTiO3 single crystals using secondary abnormal grain growth. J Eur Ceram Soc 20:1595–1597. https://doi.org/10.1016/s0955-2219(00)00030-3

Kusama T, Omori T, Saito T et al (2017) Ultra-large single crystals by abnormal grain growth. Nat Commun 8:1–8. https://doi.org/10.1038/s41467-017-00383-0

Hillert M (1965) On the theory of normal and abnormal grain growth. Acta Metall 13:227–238. https://doi.org/10.1017/CBO9781107415324.004

Anderson I, Grong Ø, Ryum N (1995) Analytical modelling of grain growth in metals and alloys in the presence of growing and dissolving precipitates—II. Abnormal grain growth. Acta Metall Mater 43:2689–2700

Thompson CV (2000) Structure evolution during processing of polycrystalline films. Annu Rev Mater Sci 30:159–190

Longworth HP, Thompson CV (1991) Abnormal grain growth in aluminum alloy thin films. J Appl Phys 69:3929–3940. https://doi.org/10.1063/1.348452

Holm EA, Miodownik MA, Rollett AD (2003) On abnormal subgrain growth and the origin of recrystallization nuclei. Acta Mater 51:2701–2716. https://doi.org/10.1016/S1359-6454(03)00079-X

Rohrer GS (2011) Grain boundary energy anisotropy: a review. J Mater Sci 46:5881–5895. https://doi.org/10.1007/s10853-011-5677-3

Dillon SJ, Harmer MP, Luo J (2009) Grain boundary complexions in ceramics and metals: an overview. JOM 61:38–44. https://doi.org/10.1007/s11837-009-0179-3

Frazier WE, Rohrer GS, Rollett AD (2015) Abnormal grain growth in the Potts model incorporating grain boundary complexion transitions that increase the mobility of individual boundaries. Acta Mater 96:390–398. https://doi.org/10.1016/j.actamat.2015.06.033

Simpson CJ, Aust KT, Winegard WC (1971) The four stages of grain growth. Metall Trans 2:987–991. https://doi.org/10.1007/BF02664229

Riontino G, Antonione C, Battezzati L et al (1979) Kinetics of abnormal grain growth in pure iron. J Mater Sci 14:86–90. https://doi.org/10.1007/BF01028331

Dennis J, Bate PS, Humphreys JF (2007) Abnormal grain growth in metals. Mater Sci Forum 558–559:717–722. https://doi.org/10.4028/www.scientific.net/msf.558-559.717

Humphreys FJ (1997) A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures—I. The basic model. Acta Mater 45:4231–4240. https://doi.org/10.1016/S1359-6454(97)00070-0

Na SM, Flatau AB (2013) Global Goss grain growth and grain boundary characteristics in magnetostrictive Galfenol sheets. Smart Mater Struct 22:125026. https://doi.org/10.1088/0964-1726/22/12/125026

Humphreys FJ (1997) A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures—II. The effect of second-phase particles. Acta Mater 45:5031–5039

Rollett AD, Mullins WW (1997) On the growth of abnormal grains. Scr Mater 36:975–980. https://doi.org/10.1016/S1359-6462(96)00501-5

Mullins WW (1956) Two-dimensional motion of idealized grain boundaries. J Appl Phys 27:900–904. https://doi.org/10.1063/1.1722511

Ferry M, Humphreys FJ (1996) Discontinuous subgrain growth in deformed and annealed 110 〈001 aluminium single crystals. Acta Mater 44:1293–1308. https://doi.org/10.1016/S0921-5093(02)00748-7

Charit I, Mishra RS, Mahoney MW (2002) Multi-sheet structures in 7475 aluminum by friction stir welding in concert with post-weld superplastic forming. Scr Mater 47:631–636. https://doi.org/10.1016/S1359-6462(02)00257-9

Hassan KAA, Norman AF, Price DA, Prangnell PB (2003) Stability of nugget zone grain structures in high strength Al-alloy friction stir welds during solution treatment. Acta Mater 51:1923–1936. https://doi.org/10.1016/S1359-6454(02)00598-0

Yu CY, Sun PL, Kao PW, Chang CP (2004) Evolution of microstructure during annealing of a severely deformed aluminum. Mater Sci Eng A 366:310–317. https://doi.org/10.1016/j.msea.2003.08.039

Ferry M, Hamilton NE, Humphreys FJ (2005) Continuous and discontinuous grain coarsening in a fine-grained particle-containing Al-Sc alloy. Acta Mater 53:1097–1109. https://doi.org/10.1016/j.actamat.2004.11.006

Charit I, Mishra RS (2008) Abnormal grain growth in friction stir processed alloys. Scr Mater 58:367–371. https://doi.org/10.1016/j.scriptamat.2007.09.052

Young JP, Askari H, Hovanski Y et al (2015) Thermal microstructural stability of AZ31 magnesium after severe plastic deformation. Mater Charact 101:9–19. https://doi.org/10.1016/j.matchar.2014.12.026

Uttarasak K, Chongchitnan W, Matsuda K et al (2019) Evolution of Fe-containing intermetallic phases and abnormal grain growth in 6063 aluminum alloy during homogenization. Results Phys 15:102535. https://doi.org/10.1016/j.rinp.2019.102535

Agnoli A, Bernacki M, Logé R et al (2015) Selective growth of low stored energy grains during δ sub-solvus annealing in the Inconel 718 nickel-based superalloy. Metall Mater Trans A Phys Metall Mater Sci 46:4405–4421. https://doi.org/10.1007/s11661-015-3035-9

Weygand D, Bréchet Y, Lépinoux J (2001) Mechanisms and kinetics of recrystallisation: a two dimensional vertex dynamics simulation. Interface Sci 9:311–317. https://doi.org/10.1023/A:1015175231826

Hurley PJ, Humphreys FJ (2003) Modelling the recrystallization of single-phase aluminium. Acta Mater 51:3779–3793. https://doi.org/10.1016/S1359-6454(03)00192-7

Radhakrishnan B, Sarma G (2004) Simulating the deformation and recrystallization of aluminum bicrystals. JOM 56:55–62. https://doi.org/10.1007/s11837-004-0074-x

Zurob HS, Bréchet Y, Dunlop J (2006) Quantitative criterion for recrystallization nucleation in single-phase alloys: prediction of critical strains and incubation times. Acta Mater 54:3983–3990. https://doi.org/10.1016/j.actamat.2006.04.028

Suwa Y, Saito Y, Onodera H (2007) Phase field simulation of stored energy driven interface migration at a recrystallization front. Mater Sci Eng A 457:132–138. https://doi.org/10.1016/j.msea.2007.01.091

Després A, Greenwood M, Sinclair CW (2020) A mean-field model of static recrystallization considering orientation spreads and their time-evolution. Acta Mater 199:116–128. https://doi.org/10.1016/j.actamat.2020.08.013

Srolovitz DJ, Grest GS, Anderson MP (1985) Computer simulation of grain growth-V. Abnormal grain growth. Acta Metall 33:2233–2247. https://doi.org/10.1016/0001-6160(85)90185-3

Rollett AD, Srolovitz DJ, Anderson MP (1989) Simulation and theory of abnormal grain growth-Anisotropic grain boundary energies and mobilities. Acta Metall 37:1227–1240

Vertyagina Y, Mahfouf M (2014) A 3D cellular automata model of the abnormal grain growth in austenite. J Mater Sci 50:745–754. https://doi.org/10.1007/s10853-014-8634-0

Suwa Y, Saito Y, Onodera H (2007) Phase-field simulation of abnormal grain growth due to inverse pinning. Acta Mater 55:6881–6894. https://doi.org/10.1016/j.actamat.2007.08.045

Liu Y, Militzer M, Perez M (2019) Phase field modelling of abnormal grain growth. Materials (Basel) 12:4048. https://doi.org/10.3390/MA12244048

Kinoshita T, Ohno M (2020) Phase-field simulation of abnormal grain growth during carburization in Nb-added steel. Comput Mater Sci 177:109558. https://doi.org/10.1016/j.commatsci.2020.109558

Zhang Y, Liu L (2021) Phase field simulation of abnormal grain growth mediated by initial particle size distribution. Adv Powder Technol 32:3395–3404. https://doi.org/10.1016/j.apt.2021.07.025

Pei R, Korte-Kerzel S, Al-Samman T (2020) Normal and abnormal grain growth in magnesium: experimental observations and simulations. J Mater Sci Technol 50:257–270. https://doi.org/10.1016/j.jmst.2020.01.014

Steinbach I, Pezzolla F, Nestler B et al (1996) A phase field concept for multiphase systems. Physica D 94:135–147

Fan D, Chen L-Q (1997) Computer simulation of grain growth using a continuum field model. Acta Mater 45:611–622

Garcke H, Nestler B, Stoth B (1999) A multiphase field concept: numerical simulations of moving phase boundaries and multiple junctions. SIAM J Appl Math 60:295–315. https://doi.org/10.1137/S0036139998334895

Steinbach I, Pezzolla F (1999) A generalized field method for multiphase transformations using interface fields. Physica D 134:385–393

Tóth GI, Pusztai T, Gránásy L (2015) Consistent multiphase-field theory for interface driven multidomain dynamics. Phys Rev B 92:184105. https://doi.org/10.1103/PhysRevB.92.184105

Kim SG, Kim DI, Kim WT, Park YB (2006) Computer simulations of two-dimensional and three-dimensional ideal grain growth. Phys Rev E 74:061605. https://doi.org/10.1103/PhysRevE.74.061605

Gruber J, Ma N, Wang Y et al (2006) Sparse data structure and algorithm for the phase field method. Model Simul Mater Sci Eng 14:1189–1195. https://doi.org/10.1088/0965-0393/14/7/007

Vedantam S, Patnaik BSV (2006) Efficient numerical algorithm for multiphase field simulations. Phys Rev E 73:016703. https://doi.org/10.1103/PhysRevE.73.016703

Moelans N, Wendler F, Nestler B (2009) Comparative study of two phase-field models for grain growth. Comput Mater Sci 46:479–490. https://doi.org/10.1016/j.commatsci.2009.03.037

Miyoshi E, Takaki T, Ohno M, Shibuta Y (2020) Accuracy evaluation of phase-field models for grain growth simulation with anisotropic grain boundary properties. ISIJ Int 60:160–167. https://doi.org/10.2355/isijinternational.isijint-2019-305

Shimokawabe T, Takaki T, Endo T et al (2011) Peta-scale phase-field simulation for dendritic solidification on the TSUBAME 2.0 supercomputer. In: Proceedings of 2011 International conference for high performance computing, networking, storage and analysis. ACM, Seattle, pp 1–11

Shibuta Y, Ohno M, Takaki T (2018) Advent of cross-scale modeling: high-performance computing of solidification and grain growth. Adv Theory Simul 1:1800065. https://doi.org/10.1002/adts.201800065

Mitsuyama Y, Takaki T, Sakane S et al (2020) Permeability tensor for columnar dendritic structures: Phase–field and lattice Boltzmann study. Acta Mater 188:282–287. https://doi.org/10.1016/j.actamat.2020.02.016

Takaki T, Sakane S, Ohno M et al (2020) Large-scale phase-field lattice Boltzmann study on the effects of natural convection on dendrite morphology formed during directional solidification of a binary alloy. Comput Mater Sci 171:109209. https://doi.org/10.1016/j.commatsci.2019.109209

Takaki T, Sakane S, Ohno M et al (2022) Phase-field study on an array of tilted columnar dendrites during the directional solidification of a binary alloy. Comput Mater Sci 203:111143. https://doi.org/10.1016/j.commatsci.2021.111143

Miyoshi E, Takaki T, Ohno M et al (2017) Ultra-large-scale phase-field simulation study of ideal grain growth. npj Comput Mater 3:25. https://doi.org/10.1038/s41524-017-0029-8

Miyoshi E, Takaki T, Ohno M et al (2019) Large-scale phase-field simulation of three-dimensional isotropic grain growth in polycrystalline thin films. Model Simul Mater Sci Eng 27:054003. https://doi.org/10.1088/1361-651X/ab1e8b

Miyoshi E, Takaki T, Sakane S et al (2021) Large-scale phase-field study of anisotropic grain growth: effects of misorientation-dependent grain boundary energy and mobility. Comput Mater Sci 186:109992. https://doi.org/10.1016/j.commatsci.2020.109992

Kirch DM, Jannot E, Barrales-Mora LA et al (2008) Inclination dependence of grain boundary energy and its impact on the faceting and kinetics of tilt grain boundaries in aluminum. Acta Mater 56:4998–5011. https://doi.org/10.1016/j.actamat.2008.06.017

Bulatov VV, Reed BW, Kumar M (2014) Grain boundary energy function for fcc metals. Acta Mater 65:161–175. https://doi.org/10.1016/j.actamat.2013.10.057

Thompson CV, Frost HJ, Spaepen F (1987) The relative rates of secondary and normal grain growth. Acta Metall 35:887–890

Gottstein G, Molodov DA, Shvindlerman LS et al (2001) Grain boundary migration: misorientation dependence. Curr Opin Solid State Mater Sci 5:9–14. https://doi.org/10.1016/S1359-0286(00)00030-9

Olmsted DL, Holm EA, Foiles SM (2009) Survey of computed grain boundary properties in face-centered cubic metals-II: Grain boundary mobility. Acta Mater 57:3704–3713. https://doi.org/10.1016/j.actamat.2009.04.015

Zhang J, Ludwig W, Zhang Y et al (2020) Grain boundary mobilities in polycrystals. Acta Mater 191:211–220. https://doi.org/10.1016/j.actamat.2020.03.044

Takaki T, Hirouchi T, Hisakuni Y et al (2008) Multi-phase-field model to simulate microstructure evolutions during dynamic recrystallization. Mater Trans 49:2559–2565. https://doi.org/10.2320/matertrans.MB200805

Ko K, Cha P, Srolovitz DJ, Hwang N (2009) Abnormal grain growth induced by sub-boundary-enhanced solid-state wetting: analysis by phase-field model simulations. Acta Mater 57:838–845. https://doi.org/10.1016/j.actamat.2008.10.030

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater 57:3694–3703. https://doi.org/10.1016/j.actamat.2009.04.007

Petrov R, Kestens L, Verbeken K, Houbaert Y (2004) Grain growth after intercritical rolling. Mater Sci Forum 467–470:305–310. https://doi.org/10.4028/www.scientific.net/msf.467-470.305

Lu N, Kang J, Shahani AJ (2021) Origins of non-random particle distributions and implications to abnormal grain growth in an Al-3.5 Wt Pct Cu Alloy. Metall Mater Trans A Phys Metall Mater Sci 52:914–927. https://doi.org/10.1007/s11661-020-06125-0

Furubayashi E (1970) An origin of the recrystallized grains with preferred orientations in cold rolled Fe-3% Si Alloy. Trans Iron Steel Inst Jpn 9:222–238. https://doi.org/10.2355/tetsutohagane1955.56.6_734

Hutchinson B (2012) Origin of Goss texture during secondary recrystallisation in silicon-steel. Mater Sci Forum 715–716:73–80. https://doi.org/10.4028/www.scientific.net/MSF.715-716.73

DeCost BL, Holm EA (2017) Phenomenology of abnormal grain growth in systems with nonuniform grain boundary mobility. Metall Mater Trans A Phys Metall Mater Sci 48:2771–2780. https://doi.org/10.1007/s11661-016-3673-6

Kundin J, Almeida RSM, Salama H et al (2020) Phase-field simulation of abnormal anisotropic grain growth in polycrystalline ceramic fibers. Comput Mater Sci 185:109926. https://doi.org/10.1016/j.commatsci.2020.109926

Miyoshi E, Takaki T, Ohno M et al (2018) Correlation between three-dimensional and cross-sectional characteristics of ideal grain growth: large-scale phase-field simulation study. J Mater Sci 53:15165–15180. https://doi.org/10.1007/s10853-018-2680-y

Anderson MP, Srolovitz DJ, Grest GS, Sahni PS (1984) Computer simulation of grain growth—I. Kinetics. Acta Metall 32:783–791. https://doi.org/10.1016/0001-6160(84)90151-2

Upmanyu M, Hassold GN, Kazaryan A et al (2002) Boundary mobility and energy anisotropy effects on microstructural evolution during grain growth. Interface Sci 10:201–216. https://doi.org/10.1023/A:1015832431826

Geiger J, Roósz A, Barkóczy P (2001) Simulation of grain coarsening in two dimensions by Cellular-Automaton. Acta Mater 49:623–629. https://doi.org/10.1016/S1359-6454(00)00352-9

He Y, Ding H, Liu L, Shin K (2006) Computer simulation of 2D grain growth using a cellular automata model based on the lowest energy principle. Mater Sci Eng A 429:236–246. https://doi.org/10.1016/j.msea.2006.05.070

Frost H, Thompson CV, Howe CL, Whang J (1988) A two-dimensional computer simulation of capillarity-driven grain growth: preliminary results. Scr Metall 22:65–70

Mason JK, Lazar EA, MacPherson RD, Srolovitz DJ (2015) Geometric and topological properties of the canonical grain growth microstructure. Phys Rev E 92:063308. https://doi.org/10.1103/PhysRevE.92.063308

Zöllner D, Streitenberger P (2006) Three-dimensional normal grain growth: Monte Carlo Potts model simulation and analytical mean field theory. Scr Mater 54:1697–1702. https://doi.org/10.1016/j.scriptamat.2005.12.042

Breithaupt T, Hansen LN, Toppaladoddi S, Katz RF (2021) The role of grain-environment heterogeneity in normal grain growth: a stochastic approach. Acta Mater 209:116699. https://doi.org/10.1016/j.actamat.2021.116699

Dimokrati A, Le Bouar Y, Benyoucef M, Finel A (2020) S-PFM model for ideal grain growth. Acta Mater 201:147–157. https://doi.org/10.1016/j.actamat.2020.09.073

Yamanaka A, Maeda Y, Sasaki K (2019) Ensemble Kalman filter-based data assimilation for three-dimensional multi-phase-field model: estimation of anisotropic grain boundary properties. Mater Des 165:107577. https://doi.org/10.1016/j.matdes.2018.107577

Miyoshi E, Ohno M, Shibuta Y et al (2021) Novel estimation method for anisotropic grain boundary properties based on Bayesian data assimilation and phase-field simulation. Mater Des 210:110089. https://doi.org/10.1016/j.matdes.2021.110089

Ishii A, Yamanaka A, Miyoshi E et al (2021) Estimation of solid-state sintering and material parameters using phase-field modeling and ensemble four-dimensional variational method. Model Simul Mater Sci Eng 29:065012. https://doi.org/10.1088/1361-651X/ac13cd

Acknowledgements

This study was supported by Grant-in-Aids for Research Activity Start-up (No. 20K22393) and for Scientific Research (A) (No. 20H00217) from the Japan Society for the Promotion of Science (JSPS) and by "Joint Usage/Research Center for Interdisciplinary Large-scale Information Infrastructures" and "High Performance Computing Infrastructure" in Japan (Project ID: jh200012).

Author information

Authors and Affiliations

Contributions

EM was responsible for conceptualization, methodology, software, investigation, formal analysis, visualization, writing the original draft, writing, reviewing, and editing, and funding acquisition. MO, YS, and AY were involved in conceptualization, methodology, and writing, reviewing, and editing. TT had contributed to conceptualization, methodology, software, writing, review, and editing, funding acquisition, supervision, and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Handling Editor: Avinash Dongare.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Miyoshi, E., Ohno, M., Shibuta, Y. et al. Validating a mean-field theory via large-scale phase-field simulations for abnormal grain growth induced by nonuniform grain boundary properties. J Mater Sci 57, 16690–16709 (2022). https://doi.org/10.1007/s10853-022-07660-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07660-4