Abstract

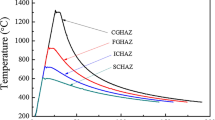

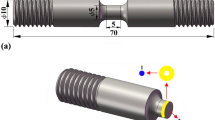

In this study, Cr-/Mo-free Cu-bearing steel with the addition of 1.5 wt% Cu was designed to improve the strength and toughness of the coarse-grained heat-affected zone (CGHAZ) at high heat input. A comparative test with traditional EH690 steel was conducted to analyze the strengthening and toughening mechanism. As heat input increased from 50 to 200 kJ/cm, microstructure of the CGHAZ for Cu-bearing steel transformed from lath/granular bainite to quasi-polygonal ferrite, while EH690 steel contained granular bainite under these conditions. The phase field simulation results showed that the increase in heat input promoted the diffusion of Cu and precipitation of nanoscale Cu-rich particles. At heat inputs of 100 kJ/cm and 200 kJ/cm, Cu-rich particles with sizes of 3.8 nm and 7.5 nm precipitated in the CGHAZ, providing precipitation strengthening increment of 47 MPa and 167 MPa, respectively. The precipitation strengthening of nanoscale Cu-rich particles compensated for the strength loss caused by the ferritic transformation of Cu-bearing steel. Low carbon and Cr-/Mo-free for Cu-bearing steel reduced the content of M-A constituents, leading to the increase in crack propagation energy and toughness. Under heat input of 200 kJ/cm, tensile strength, yield strength and impact energy at -40 °C of CGHAZ for Cu-bearing steel were 975 MPa, 837 MPa and 63.7 J, respectively, exhibiting the good mechanical properties under high heat input condition.

Similar content being viewed by others

References

Lan LY, Qiu CL, Zhao DW, Gao XH, Du LX (2011) Microstructural characteristics and toughness of the simulated coarse grained heat affected zoned of high strength low carbon bainitic steel. Mater Sci Eng A 529:192–200. https://doi.org/10.1016/j.msea.2011.09.017

Nie Y, Shang CJ, Song X, You Y, Li C, He XL (2010) Properties and homogeneity of 550MPa grade TMCP steel for ship hull. Int J Miner Metall Mater 17:179–184. https://doi.org/10.1007/s12613-010-0210-2

Antonio A, Palorobrto M (2004) Austenite transformation and age hardening of HSLA-80 and ULCB steels. J Mater Process Tech 155:1513–1518. https://doi.org/10.1016/j.jmatprotec.2004.04.245

Joyce JA, Link RE, Roe C, Sobotka JC (2010) Dynamic and static characterization of compact crack arrest tests of navy and nuclear steels. Eng Fract Tech 77:337–347. https://doi.org/10.1016/j.engfracmech.2009.04.006

Kumar S, Nath SK, Kumar V (2016) Continuous cooling transformation behavior in the weld coarse grained heat affected zone and mechanical properties of Nb-microalloyed and HY85 steels. Mater Design 90:177–184. https://doi.org/10.1016/j.matdes.2015.10.071

Zhou PS, Wang B, Wang L, Hu YW, Zhou L (2018) Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel. Mater Sci Eng A 722:112–121. https://doi.org/10.1016/j.msea.2018.03.029

Di XJ, Tong M, Li CN, Zhao C, Wang DP (2019) Microstructural evolution and its influence on toughness in simulated inter-critical heat affected zone of large thickness bainitic steel. Mater Sci Eng A 743:67–76. https://doi.org/10.1016/j.msea.2018.11.070

Far AH, Anjidan SM, Abbasi S (2019) The effect of increasing Cu and Ni on a significant enhancement of mechanical properties of high strength low alloy, low carbon steels of HSLA-100 type. Mater Sci Eng A 746:384–393. https://doi.org/10.1016/j.msea.2019.01.025

Hu J, Du LX, Wang JJ (2013) Effect of welding heat input on microstructures and toughness in simulated CGHAZ of V-N high strength steel. Mater Sci Eng A 577:161–168. https://doi.org/10.1016/j.msea.2013.04.044

Kumar S, Nath SK (2016) Effect of heat input on impact toughness in transition temperature region of weld CGHAZ of a HY 85 steel. J Mater Process Tech 55:216–224. https://doi.org/10.1016/j.jmatprotec.2016.05.018

Lei XW, Zhou SB, Huang JH (2020) Current status and development trend on weldability of ultra-high strength hull structure steel. Chinese J Mater Res 34:1–15. https://doi.org/10.11901/1005.3093.2019.371

Yu HW, Wu KM, Dong BQ, Yu LL, Liu JX, Liu ZC, Xiao DH, Jing X, Liu HK (2019) Effect of niobium on the microstructure and mechanical properties of simulated coarse-grained heat-affected zone (CGHAZ) of high-strength low-alloy (HSLA) steels. Materials 15:3318–3327. https://doi.org/10.3390/ma15093318

Wang L, Wu LB, He S, Xu M, Cui CW, Wu D, Zhou PS, Hu YW (2022) Effect of heat input on microstructure and impact toughness in the simulated coarse-grained heat-affected zones of X90 pipeline steel. J Mater Eng Perform 22:0719–0737. https://doi.org/10.1007/s11665-022-07093-9

Yang XC, Di XJ, Liu XG, Wang DP, Li CN (2019) Effect of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels. Mater Charact 155:109818–109829. https://doi.org/10.1016/j.matchar.2019.109818

Ramachandran DC, Moon J, Lee J, Lee CH, Kim SD, Chung JH, Biro E, Park YD (2021) Role of bainitic microstructure with M-A constituent on the toughness of an HSLA steel for seismic resistant structural applications. Mater Sci Eng A 801:140390–140401. https://doi.org/10.1016/j.msea.2020.140390

Lee SG, Sohn SS, Kim B, Kim WG, Um KK, Lee S (2018) Effect of martensite-austenite constituent on crack initiation and propagation in inter-critical heat-affected zone of high-strength low-alloy (HSLA) alloy. Mater Sci Eng A 715:332–339. https://doi.org/10.1016/j.msea.2018.01.021

Zhang YH, Yang J, Liu DK, Pan XQ, Xu LY (2021) Improvement of impact toughness of the welding heat-affected zone in high-strength low-alloy steels through Ca deoxidation. Metall Mater Trans A 52:668–679. https://doi.org/10.1007/s11661-020-06105-4

Lin CK, Pan YC, Su YHF, Lin GR, Hwang WS, Kuo JC (2018) Effect of Mg-Al-O-Mn-S inclusion on the nucleation of acicular ferrite in magnesium-containing low-carbon steel. Mater Char 141:318–327. https://doi.org/10.1016/j.matchar.2018.05.005

Adabavazeh Z, Hwang WS, Su YH (2017) Effect of adding cerium on microstructure and morphology of Ce-based inclusions formed in low-carbon steel. Sci Rep 7:46503–46513. https://doi.org/10.1038/srep46503

Yu HW, Wu KM, Dong BQ, Liu JX, Liu ZC, Xiao DH, Jin X, Liu HK, Tai MM (2022) Effect of heat-input on microstructure and toughness of CGHAZ in a high-Nb-content microalloyed HSLA steel. Materials 15:3588–3597. https://doi.org/10.3390/ma15103588

Geng RM, Li J, Shi CB, Zhi JG, Lu B (2022) Effect of Ce on microstructures, carbides and mechanical properties in simulated coarse-grained heat-affected zone of 800-MPa high-strength low-alloy steel. Mater Sci Eng A 840:142919–142933. https://doi.org/10.1016/j.msea.2022.142919

Shen Y, Wan XL, Liu Y, Li GQ, Xue ZL, Wu KM (2019) The significant impact of Ti content on microstructure-toughness relationship in the simulated coarse-grained heated-affected zone of high-strength low-alloy steels. Ironmak Steelmak 48:584–596. https://doi.org/10.1080/03019233.2018.1533608

Cao YX, Wan XL, Zhou F, Wang Y, Liu XB, Wu KM, Li GQ (2022) Effect of Ce content on microstructure-toughness relationship in the simulated coarse-grained heat-affected zone of high-strength low-alloy steels. Metals 11:2003–2026. https://doi.org/10.3390/met11122003

Tervo H, Kaijalainen A, Pallaspuro S, Anttila S, Mehtonen S, Porter D, Komi J (2020) Low-temperature toughness properties of 500 MPa offshore steels and their simulated coarse-grained heat-affected zones. Mater Sci Eng A 773:138719–138731. https://doi.org/10.1016/j.msea.2019.138719

Wang J, Shen YF, Xue WY, Jia N, Misra RDK (2021) The significant impact of introducing nanosize precipitates and decreased effective grain size on retention of high toughness of simulated heat affected zone (HAZ). Mater Sci Eng A 803:140484–140501. https://doi.org/10.1016/j.msea.2020.140484

Narimani M, Hajjari E, Eskandari M, Szpunar JA (2022) Electron backscattered diffraction characterization of S900 HSLA steel welded joints and evolution of mechanical properties. J Mater Eng Perform 31:3985–3997. https://doi.org/10.1007/s11665-021-06454-0

Sun MX, Xu Y, Xu TW (2020) Cu precipitation behavior and microscopic mechanical characteristics of a novel ultra-low carbon steel. Materials 13:3571–3583. https://doi.org/10.3390/ma13163571

Ramirez AJ, Brandi SD (2004) Application of discrete distribution point heat source model to simulate multipass weld thermal cycles in medium thick plates. Sci Technol Weld Joi 9:72–82. https://doi.org/10.1179/136217104225017189

Li CN, Duan R, Fu W, Gao HS, Wang DP, Di XJ (2021) Improvement of mechanical properties for low carbon ultra-high strength steel strengthened by Cu-rich multistructured precipitation via modification to bainite. Mater Sci Eng A 817:141337–141350. https://doi.org/10.1016/j.msea.2021.141337

Koyama T, Onodera H (2005) Computer simulation of phase decomposition in Fe-Cu-Mn-Ni quaternary alloy based on the phase-field method. Mater Trans 46:1187–1192. https://doi.org/10.2320/matertrans.46.1187

Liu DD, Zhang LJ, Du Y, Jin ZP (2015) Simulation of atomic mobilities, diffusion coefficients and diffusion paths in bcc_A2 and bcc_B2 phase of the Al-Ni-Fe system. J Alloy Compd 634:148–155. https://doi.org/10.1016/j.jallcom.2015.01.267

Sun YY, Zhao YH, Zhao BJ, Yang WK, Li XL, Hou H (2019) Phase-field modeling of microstructure evolution of Cu-rich phase in Fe-Cu-Mn-Ni-Al quinary system coupled with thermodynamic database. J Mater Sci 54:11263–11278. https://doi.org/10.1007/s10853-019-03678-3

Fu W, Li CN, Duan R, Gao HS, Di XJ, Wang DP (2022) Formation mechanism of CuNiAl-rich multi-structured precipitation and its effect on mechanical properties for ultra-high strength low carbon steel obtained via direct quenching and tempering process. Mater Sci Eng A 833:142567–142578. https://doi.org/10.1016/j.msea.2021.142567

Yu XH, Caron JL, Babu SS, Lippold JC, Ishem D, Seidman DN (2011) Strength recovery in a high-strength steel during multiple weld thermal simulations. Metall Mater Trans A 42A:3669–3679. https://doi.org/10.1007/s11661-011-0707-y

Hunter AH, Farren JD, Dupont JN, Seidman DN (2013) An atom-probe tomographic study of arc welds in a multi-component high-strength low-alloy steel. Metall Mater Trans A 44A:1741–1759. https://doi.org/10.1007/s11661-012-1518-5

Niu MC, Zhou G, Wang W, Shahzad MB, Shan YY, Yang K (2019) Precipitate evolution and strengthening behavior during aging process in a 2.5 GPa grade maraging steel. Acta Mater 179:296–307. https://doi.org/10.1016/j.actamat.2019.08.042

Wang JS, Mulholland MC, Olson GB, Seidman DN (2013) Prediction of the yield strength of a secondary-hardening steel. Acta Mater 61:4939–4952. https://doi.org/10.1016/j.actamat.2013.04.052

Cui JJ, Zhu WT, Chen ZY, Chen LQ (2019) Effect of simulated cooling time on microstructure and toughness of CGHAZ in novel high-strength low-carbon construction steel. Sci Technol Weld Join 25:169–177. https://doi.org/10.1080/13621718.2019.1661116

Shi L, Yan ZS, Liu YC, Zhang C, Qiao ZX, Ning BQ, Li HJ (2014) Improved toughness and ductility in ferrite/acicular ferrite dual-phase steel through intercritical heat treatment. Mater Sci Eng A 590:7–15. https://doi.org/10.1016/j.msea.2013.10.006

Zhang XL, Jiang ZQ, Li SX, Fan JW (2016) Effect of effective grain size and grain boundary of large misorientation on upper shelf energy in pipeline steels. J Wuhan Univ Technol 31:606–610. https://doi.org/10.1007/s11595-016-1417-5

Lee SG, Sohn SS, Kim B, Kim WG, Um KK, Lee SH (2018) Effect of martensite-austenite constituent on crack initiation and propagation in inter-critical heat-affected zone of high-strength low-alloy (HSLA) steel. Mater Sci Eng A 715:332–339. https://doi.org/10.1016/j.msea.2018.01.021

Bonnevie E, Ferriere G, Ikhlef A, Kaplan D, Orain JM (2004) Morphological aspects of martensite-austenite constituents in intercritical and coarse grain heat affected zones of structural steel. Mater Sci Eng A 385:352–358. https://doi.org/10.1016/j.msea.2004.06.033

Peng K, Yang CL, Fan CL, Lin SB (2018) Microstructure and mechanical properties of simulated unaltered coarse grained heat affected zones of 10CrNi3MoV steel by double-sided double arc welding. J Mater Process Tech 251:225–231. https://doi.org/10.1016/j.jmatprotec.2017.08.032

Takayama N, Miyamoto G, Furuhara T (2018) Chemistry and three-dimensional morphology of martensite-austenite constituent in the bainite structure of low-carbon low-alloy steels. Acta Mater 145:154–164. https://doi.org/10.1016/j.actamat.2017.11.036

Xi XH, Wang JL, Chen LQ, Wang ZD (2020) On the role of Cu addition in toughness improvement of coarse grained heat affected zone in a low carbon high strength steel. J Mater Sci 55:10863–10877. https://doi.org/10.1007/s10853-020-04710-7

Xu XN, Tian Y, Ye QB, Misra RDK, Wang ZD (2021) The significant impact of the characteristics of granular structure and granular bainite on the mechanisms contributing to strength-ductility combination. J Mater Eng Perform 30:7479–7487. https://doi.org/10.1007/s11665-021-05887-x

Funding

This study was financially funded by National Natural Science Foundation of China (Grant No. 52074191).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, W., Li, C., Di, X. et al. Strengthening and toughening mechanism of coarse-grained heat-affected zone for the Cr-/Mo-free Cu-bearing HSLA steel under high heat input welding conditions. J Mater Sci 57, 16471–16489 (2022). https://doi.org/10.1007/s10853-022-07631-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07631-9