Abstract

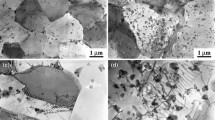

The friction stir welded joint of wrought ZM21 alloy was divided into five parts, and their localized creep behavior was studied via the impression method. The tests were carried out in the stress range of 300–450 MPa (σimp/G ≈ 0.02–0.03) and in the temperature range of 448–523 K. Optical and SEM micrographs and EDS taken before and after the impression tests were used to study the microstructure of various zones of the FS welded joint. Power law was found to satisfactorily relate the stress and strain rates. The steady-state impression velocity was found to vary significantly between the advancing and retreating sides of TMAZ and HAZ. For TMAZ, the creep exponent on the AS was 4.8, and on the RS, it was 7.8. The activation energy on the AS was ~ 133 kJ/mol, and on the RS, it was ~ 101 kJ/mol. Similarly, for HAZ, the creep exponent on the AS was found to be 5.5 and on the RS, it was 4.9. The activation energy on the AS was ~ 86 kJ/mol and on the RS, it was ~ 232 kJ/mol. The cross-over of steady-state impression velocity of different zones indicates that the weak zone was temperature and stress dependent. Within the stresses and temperatures studied, the weld zone's creep resistance (i.e., lower minimum impression velocity) was found to be better than the base material. As it is with most magnesium alloys, dislocation climb was found to be the operative mechanism in the FS weldments of ZM21 alloy. The rate-controlling mechanism remains to be identified because the wide variation in n and Q values suggests that different creep mechanisms are in operation in different zones.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data is part of an ongoing study.

References

Mordike BL, Ebert T (2001) Magnesium properties—applications—potential. Mater Sci Eng A 302:37–45

Pollock M (2010) Materials science: weight loss with magnesium alloys. Science 328:986–987

Polmear IJ (1994) Magnesium alloys and applications. Mater Sci Technol 10:1–16

Wu G, Wang C, Sun M, Ding W (2021) Recent developments and applications on high-performance cast magnesium rare-earth alloys. J Magnes Alloy 9:1–20

Weiler JP (2021) Exploring the concept of castability in magnesium die-casting alloys. J Magnes Alloy 9:102–111

You S, Huang Y, Kainer KU, Hort N (2017) Recent research and developments on wrought magnesium alloys. J Magnes Alloy 5:239–253

Siebert-Timmer A, Fletcher M, Bichler L, Sediako D (2013) Creep performance of wrought AX30 and EZ33 magnesium alloys. Can Metall Q 52:430–438

Letzig D, Swiostek J, Bohlen J, Beaven PA, Kainer KU (2008) Wrought magnesium alloys for structural applications. Mater Sci Technol 24:991–996

Sillekens WH, Schade van Westrum JAFM, den Bakker AJ, Vet PJ (2003) Hydrostatic extrusion of magnesium: process mechanics and performance. Mater Sci Forum 426–432:629–636

Alizadeh R, Mahmudi R, Langdon TG (2013) Creep mechanisms in an Mg–4Zn alloy in the as-cast and aged conditions. Mater Sci Eng A 564:423–430

Boehlert CJ (2007) The tensile and creep behavior of Mg–Zn Alloys with and without Y and Zr as ternary elements. J Mater Sci 42:3675–3684

Tayebi M, Najafi H, Nategh S, Khodabandeh A (2021) Creep behavior of ZK60 alloy and ZK60/SiCw composite after extrusion and precipitation hardening. Met Mater Int 27:3905–3917

Spigarelli S, El Mehtedi M, Regev M, Gariboldi E, Lecis N (2012) High temperature creep and superplasticity in a Mg–Zn–Zr alloy. J Mater Sci Technol 28(5):407–413

Xie GM, Ma ZY, Geng L, Chen RS (2007) Microstructural evolution and mechanical properties of friction stir welded Mg–Zn–Y–Zr alloy. Mater Sci Eng A 471:63–68

Yajie L, Fengming Q, Cuirong L, Zhisheng W (2017) A review: effect of friction stir welding on microstructure and mechanical properties of magnesium alloys. Metals 524:1–14

Regev M, Spigarelli S, Cabibbo M (2015) Microstructure stability during creep of friction stir welded AZ31B magnesium alloy. J Manuf Sci Eng Trans ASME 137:1–8

Singh K, Singh G, Singh H (2018) Review on friction stir welding of magnesium alloys. J Magnes Alloy 6:399–416

Yu S, Chen X, Huang Z, Liu Y (2010) Microstructure and mechanical properties of friction stir welding of AZ31B magnesium alloy added with cerium. J Rare Earths 28:316–320

Thomas WM, Nicholas ED, Needham JC, Murch MG, Templesmith P, Dawes CJ (1991) International patent application no. PCT/GB92/02203 and GB Patent Application No. 9125978.8

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78

Yang J, Wang D, Xiao BL, Ni DR, Ma ZY (2013) Effects of rotation rates on microstructure, mechanical properties, and fracture behavior of friction stir-welded (FSW) AZ31 magnesium alloy. Metall Mater Trans A 44:517–530

Yang J, Xiao BL, Wang D, Ma ZY (2010) Effects of heat input on tensile properties and fracture behavior of friction stir welded Mg–3Al–1Zn alloy. Mater Sci Eng A 527:708–714

Esparza JA, Davis WC, Trillo EA, Murr LE (2002) Friction-stir welding of magnesium alloy AZ31B. J Mater Sci Lett 21:917–920

Carlone P, Astarita A, Rubino F, Pasquino N (2016) Microstructural aspects in FSW and TIG welding of cast ZE41A magnesium alloy. Metall Mater Trans B 47:1340–1346

Spigarelli S, Regev M, el Mehtedi M, Quercettia G, Cabibboa M (2011) Analysis of the effect of friction stir welding on the minimum creep rate of an Mg-3% Al-1% Zn alloy. Scr Mater 65:626–629

Dobriyal RP, Dhindaw BK, Muthukumaran S, Mukherjee SK (2008) Microstructure and properties of friction stir butt-welded AE42 magnesium alloy. Mater Sci Eng A 477:243–249

Regev M, Spigarelli S (2013) Plastic deformation mechanisms of base material and friction stir welded AZ31B-H24 magnesium alloy. Mater Sci Appl 04:357–364

Dyson CC, Sun W, Hyde CJ, Brett SJ, Hyde TH (2016) Use of small specimen creep data in component life management: a review. Mater Sci Technol 32:1567–1581

Pekguleryuz MO, Kaya AA (2003) Creep resistant magnesium alloys for powertrain applications. Adv Eng Mater 5:866–878

Sakthivel T, Sasikala G, Vasudevan M (2020) Role of microstructures on heterogeneous creep behaviour across P91 steel weld joint assessed by impression creep testing. Mater Charact 159:1–14

Naveena VVD, Ganesan V, Laha K, Mathew MD (2014) Evaluation of creep deformation behaviour of different microstuctural zones of 316LN SS weld joint using impression creep testing technique. Mater Sci Technol 30:1223–1228

Yadav SD, Vasantharaja P, Riedlsperger F, Nagaraju S, Vasudevan M (2019) Zone-wise investigation of creep behaviour 9Cr–1Mo steel weld joints. Mater Sci Technol 35:155–172

Zhang W, Wang X, Wang Y, Yu X, Gao Y, Feng Z (2020) Type IV failure in weldment of creep resistant ferritic alloys: I. Micromechanical origin of creep strain localization in the heat affected zone. J Mech Phys Solids 134:1–26

Wang Y, Zhang W, Wang Y, Lim YC, Yu X, Feng Z (2021) Experimental evaluation of localized creep deformation in grade 91 steel weldments. Mater Sci Eng A 799:1–12

Sastry DH (2005) Impression creep technique: an overview. Mater Sci Eng A 409:67–75

Chu SNG, Li JCM (1977) Impression creep; a new creep test. J Mater Sci 12:2200–2208

Yang F, Li JCM (2013) Impression test: a review. Mater Sci Eng R Rep 74:233–253

Hyde TH, Sun W, Williams JA (2007) Requirements for and use of miniature test specimens to provide mechanical and creep properties of materials: a review. Int Mater Rev 52:213–255

Ebenezer D, Koteswara Rao SR, Vijayan S, Rajeswari R (2022) High temperature impression creep behavior and microstructures of wrought ZM21 magnesium alloy. Proc Inst Mech Eng Pt L J Mater Des Appl 236:524–532

Ebenezer D, Rao SRK (2022) Impression creep behavior of an Mg–Zn–RE alloy at elevated temperatures. Metall Mater Trans A 53:823–836

Kassner ME, Pérez-Prado M-T (2004) Fundamentals of creep in metals and alloys, 1st edn. Elsevier, Oxford

Peng L, Yang F, Nie JF, Li JCM (2005) Impression creep of a Mg–8Zn–4Al–0.5Ca alloy. Mater Sci Eng A 410–411:42–47

Zhu SM, Nie JF, Gibson MA, Easton MA, Bakke P (2012) Microstructure and creep behavior of high-pressure die-cast magnesium alloy AE44. Metall Mater Trans A 43:4137–4144

Ansary S, Mahmudi R, Esfandyarpour MJ (2012) Creep of AZ31 Mg alloy: a comparison of impression and tensile behavior. Mater Sci Eng A 556:9–14

Naghdi F, Mahmudi R (2014) Impression creep behavior of the extruded Mg–4Zn–0.5Ca and Mg–4Zn–0.5Ca–2RE alloys. Mater Sci Eng A 616:161–170

Wang H, Wang QD, Boehlert CJ, Yang J, Yin DD, Yuan J, Ding WJ (2016) The impression creep behavior and microstructure evolution of cast and cast-then-extruded Mg–10Gd–3Y–0.5Zr (wt%). Mater Sci Eng A 649:313–324

Zhang Y, Huo Q, Zhang Z, Xiao Z, Wang C, Hashimoto A, Yang X (2021) Effects of yttrium content on the three-dimensional compressive creep anisotropy of Mg–Y alloys. Metall Mater Trans A 52:3910–3930

Yang F, Li JCM (1995) Impression test of 63Sn37Pb eutectic alloy. Mater Sci Eng A 201:40–49

Wang J, Zhang X (2016) Twinning effects on strength and plasticity of metallic materials. MRS Bull 41:274–281

Commin L, Rotinat R, Pierron F, Masse JE, Barrallier L (2009) Identification of shear bands in wrought magnesium alloy friction stir welds and laser beam welds. Mater Sci Technol 25:1215–1221

Cabibbo M, Ricci P, Regev M (2011) Nanoindentation applied to an optimized FSW-AZ31 butt joint. Kovove Mater 49:233–242

Crossland IG, Jones RB (1972) Dislocation creep in magnesium. Met Sci J 6:162–166

Vagarali SS, Langdon TG (1982) Deformation mechanisms in h.c.p. metals at elevated temperatures-II. creep behavior of a Mg-0.8% Al solid solution alloy. Acta Metall 30:1157–1170

Golmakaniyoon S, Mahmudi R (2011) Microstructure and creep behavior of the rare-earth doped Mg–6Zn–3Cu cast alloy. Mater Sci Eng A 528:1668–1677

Ebenezer D, Koteswara Rao SR, Harikrishna KL, Madhusudhan Reddy G (2022) Impression creep behavior of different zones in friction stir welded ZE41 magnesium-rare earth alloy. Mater Sci Eng A 851:143615. https://doi.org/10.1016/j.msea.2022.143615

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All the authors are involved in conceptualization, experimentation, analysis, and writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ebenezer, D., Koteswara Rao, S.R. & Harikrishna, K.L. Impression creep behavior of different zones in friction stir welded Mg–Zn–Mn wrought alloy. J Mater Sci 57, 15059–15077 (2022). https://doi.org/10.1007/s10853-022-07522-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07522-z