Abstract

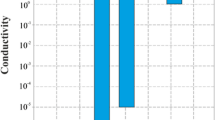

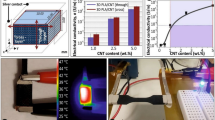

The electrically conductive and optically transparent flexible nanocomposites made of polymers and multi-walled carbon nanotube (MWCNT) have the potential to be used as a transparent substrate for optoelectronic applications. In this investigation, we have fabricated a series of nanocomposites of MWCNT, used as conductive filler, with a copolymer of methyl methacrylate and acrylonitrile as a matrix, and solution blending method was used to achieve suitable dispersions. The MWCNT content varied sequentially in these nanocomposite thin films. A detailed study about the dispersion of MWCNTs in the matrix was done by attenuated total reflectance-infrared spectroscopy, Raman spectroscopy, scanning electron microscopy, and X-ray photoelectron spectroscopy. The surface roughness is continuously increasing with an increase in the amount of conductive filler in the polymer matrix. However, it never exceeds 10 nm, which is very small compared to the MWCNT length, and also confirmed nearly complete embedding of conducting filler in the insulating matrix. The diffusion coefficient of nanocomposite was investigated for O2 and H2O with Molecular Dynamics simulations and found to decrease with increasing load percentage of MWCNT. The thin film’s optical transmittance and electrical conductivity are characterized thoroughly. An optimized formulation of nanocomposite with 0.25% MWCNT has shown enhanced conductivity of 10–2 S/cm (semiconductive range) with ~ 94% optical transparency at 550 nm.

Graphical abstract

Similar content being viewed by others

References

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Zhang W, Phang IY, Shen L et al (2004) Polymer nanocomposites using urchin-shaped carbon nanotube-silica hybrids as reinforcing fillers. Macromol Rapid Commun 25:1860–1864

Park SJ, Cho MS, Lim ST et al (2005) Electrorheology of multiwalled carbon nanotube/poly (methyl methacrylate) nanocomposites. Macromol Rapid Commun 26:1563–1566

Hwang B-Y, Choi S-H, Lee K-W, Kim J-Y (2018) Highly stretchable and transparent electrode film based on SWCNT/Silver nanowire hybrid nanocomposite. Compos Part B Eng 151:1–7

Pradhan AK, Swain SK (2013) Synthesis and characterization of poly(acrylonitrile-co-methylmethacrylate) nanocomposites reinforced by functionalized multiwalled carbon nanotubes. Iran Polym J 22:369–376

Shankar U, Gupta CR, Oberoi D et al (2020) A facile way to synthesize an intrinsically ultraviolet-C resistant tough semiconducting polymeric glass for organic optoelectronic device application. Carbon N Y 168:485–498

Zheng W, Wong S-C (2003) Electrical conductivity and dielectric properties of PMMA/expanded graphite composites. Compos Sci Technol 63:225–235

Wang Z, Lu M, Li H-L, Guo X-Y (2006) SWNTs–polystyrene composites preparations and electrical properties research. Mater Chem Phys 100:77–81

Hermant MC, Verhulst M, Kyrylyuk AV et al (2009) The incorporation of single-walled carbon nanotubes into polymerized high internal phase emulsions to create conductive foams with a low percolation threshold. Compos Sci Technol 69:656–662

Zou J, Liu L, Chen H et al (2008) Dispersion of pristine carbon nanotubes using conjugated block copolymers. Adv Mater 20:2055–2060

Kim ST, Choi HJ, Hong SM (2007) Bulk polymerized polystyrene in the presence of multiwalled carbon nanotubes. Colloid Polym Sci 285:593–598

Petrov P, Lou X, Pagnoulle C et al (2004) Functionalization of multi-walled carbon nanotubes by electrografting of polyacrylonitrile. Macromol Rapid Commun 25:987–990

Park WK, Kim JH, Lee S-S et al (2005) Effect of carbon nanotube pre-treatment on dispersion and electrical properties of melt mixed multi-walled carbon nanotubes/poly (methyl methacrylate) composites. Macromol Res 13:206–211

Yu J, Lu K, Sourty E et al (2007) Characterization of conductive multiwall carbon nanotube/polystyrene composites prepared by latex technology. Carbon N Y 45:2897–2903

Bauhofer W, Kovacs JZ (2009) A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos Sci Technol 69:1486–1498

Chen J, Liu B, Gao X, Xu D (2018) A review of the interfacial characteristics of polymer nanocomposites containing carbon nanotubes. RSC Adv 8:28048–28085

Shankar U, Bhandari S, Khastgir D (2019) Carbon Black-Filled Nitrile Rubber Composite as a Flexible Electrode for Electrochemical Synthesis of Supercapacitive Polyaniline. Polym Compos 40:E1537–E1547

Abraham JK, Philip B, Witchurch A et al (2004) A compact wireless gas sensor using a carbon nanotube/PMMA thin film chemiresistor. Smart Mater Struct 13:1045–1049

Kang X, Ma W, Zhang H et al (2008) Vinyl–carbon nanotubes for composite polymer materials. J Appl Polym Sci 110:1915–1920

Park C, Ounaies Z, Watson KA et al (2002) Dispersion of single wall carbon nanotubes by in situ polymerization under sonication. Chem Phys Lett 364:303–308

Sethi SK, Soni L, Manik G (2018) Component compatibility study of poly(dimethyl siloxane) with poly(vinyl acetate) of varying hydrolysis content: An atomistic and mesoscale simulation approach. J Mol Liq 272:73–83

Sethi SK, Manik G (2021) A combined theoretical and experimental investigation on the wettability of MWCNT filled PVAc-g-PDMS easy-clean coating. Prog Org Coatings 151:106092

O’connell ST, Thompson PA (1995) Molecular dynamics–continuum hybrid computations: a tool for studying complex fluid flows. Phys Rev E 52:R5792

Sharma S, Pathak AK, Singh VN et al (2018) Excellent mechanical properties of long multiwalled carbon nanotube bridged Kevlar fabric. Carbon N Y 137:104–117

Material StudioTM, by Dassault Systemes BIOVIA, UK (Accelrys®). http://accelrys.com/products/materials-studio

Du D, Tang C, Zhang J, Hu D (2020) Effects of hydrogen sulfide on the mechanical and thermal properties of cellulose insulation paper: A molecular dynamics simulation. Mater Chem Phys 240:122153

Tang Y, Tang C, Hu D, Gui Y (2018) Effect of aminosilane coupling agents with different chain lengths on thermo-mechanical properties of cross-linked epoxy resin. Nanomaterials 8:

Sethi SK, Shankar U, Manik G (2019) Fabrication and characterization of non-fluoro based transparent easy-clean coating formulations optimized from molecular dynamics simulation. Prog Org Coatings 136:105306

Sethi SK, Soni L, Shankar U, et al (2020) A molecular dynamics simulation study to investigate poly (vinyl acetate)-poly (dimethyl siloxane) based easy-clean coating: An insight into the surface behavior and substrate interaction. J Mol Struct 1202:127342

Hu D, Yan L, Liu T et al (2019) Solubility and diffusion behavior of compressed CO2 in polyurethane oligomer. J Appl Polym Sci 136:47100

Shankar U, Oberoi D, Avasarala S et al (2019) Design and fabrication of a transparent, tough and UVC screening material as a substitute for glass substrate in display devices. J Mater Sci 54:6684–6698. https://doi.org/10.1007/s10853-018-03285-8

Dresselhaus MS, Jorio A, Souza Filho AG, Rjpt S (2010) Defect characterization in graphene and carbon nanotubes using Raman spectroscopy. Philos Trans R Soc A Math Phys Eng Sci 368:5355–5377

Coccato A, Jehlicka J, Moens L, Vandenabeele P (2015) Raman spectroscopy for the investigation of carbon-based black pigments. J Raman Spectrosc 46:1003–1015

Bokobza L, Zhang J (2012) Raman spectroscopic characterization of multiwall carbon nanotubes and of composites. Express Polym Lett 6:

Hadavand BS, Javid KM, Gharagozlou M (2013) Mechanical properties of multi-walled carbon nanotube/epoxy polysulfide nanocomposite. Mater Des 50:62–67

Mishra SK, Tripathi SN, Choudhary V, Gupta BD (2015) Surface plasmon resonance-based fiber optic methane gas sensor utilizing graphene-carbon nanotubes-poly (methyl methacrylate) hybrid nanocomposite. Plasmonics 10:1147–1157

Rao AM, Eklund PC, Bandow S et al (1997) Evidence for charge transfer in doped carbon nanotube bundles from Raman scattering. Nature 388:257–259

Jyoti J, Basu S, Singh BP, Dhakate SR (2015) Superior mechanical and electrical properties of multiwall carbon nanotube reinforced acrylonitrile butadiene styrene high performance composites. Compos Part B Eng 83:58–65

Hu C, Chen X, Chen J et al (2012) Observation of mutual diffusion of macromolecules in PS/PMMA binary films by confocal Raman microscopy. Soft Matter 8:4780–4787

Kuang Y, He H, Chen S et al (2019) Adsorption behavior of CO 2 on amine-functionalized polyacrylonitrile fiber. Adsorption 25:693–701

Bokobza L, Rahmani M (2009) Carbon nanotubes: Exceptional reinforcing fillers for silicone rubbers. KGK, Kaut Gummi Kunstst 62:112–117

Parija S, Bhattacharyya AR (2016) Role of interfacial interactions to control the extent of wrapping of polymer chains on multi-walled carbon nanotubes. RSC Adv 6:42334–42346

Odian G (2004) Chain Copolymerization. In: Principles of polymerization, 4th ed. John Wiley & Sons, pp 464–541

Shrivastava NK, Khatua BB (2011) Development of electrical conductivity with minimum possible percolation threshold in multi-wall carbon nanotube/polystyrene composites. Carbon N Y 49:4571–4579

Wang S, Xuan S, Jiang W et al (2015) Rate-dependent and self-healing conductive shear stiffening nanocomposite: a novel safe-guarding material with force sensitivity. J Mater Chem A 3:19790–19799

Wang L, Wang X, Li Y (2012) Relation between repeated uniaxial compressive pressure and electrical resistance of carbon nanotube filled silicone rubber composite. Compos Part A Appl Sci Manuf 43:268–274

Khan W, Sharma R, Saini P (2016) Carbon nanotube-based polymer composites: synthesis, properties and applications. Carbon Nanotub Prog their Polym Compos

Kaseem M, Hamad K, Ko YG (2016) Fabrication and materials properties of polystyrene/carbon nanotube (PS/CNT) composites: a review. Eur Polym J 79:36–62

Yu K, Liu Y, Leng J (2014) Shape memory polymer/CNT composites and their microwave induced shape memory behaviors. RSC Adv 4:2961–2968

Wu M, Wu Y, Liu Z, Liu H (2012) Optically transparent poly(methyl methacrylate) composite films reinforced with electrospun polyacrylonitrile nanofibers. J Compos Mater 46:2731–2738

Eadie GB, Rindza MIB, Lynn RIAF, et al (2015) Refractive index measurements of poly ( methyl methacrylate ) ( PMMA ) from 0 . 4 – 1 . 6 μ m. 54:139–143

Bisht A, Kumar V, Maity PC, et al (2019) Strong and transparent PMMA sheet reinforced with amine functionalized BN nanoflakes for UV-shielding application. Compos Part B Eng 176:107274

AlFannakh H, Arafat SS, Ibrahim SS (2019) Synthesis, electrical properties, and kinetic thermal analysis of polyaniline/polyvinyl alcohol-magnetite nanocomposites film. Sci Eng Compos Mater 26:347–359

Grossiord N, Loos J, Koning CE (2005) Strategies for dispersing carbon nanotubes in highly viscous polymers. J Mater Chem 15:2349–2352

Marsden AJ, Papageorgiou DG, Vallés C, et al (2018) Electrical percolation in graphene–polymer composites. 2D Mater 5:32003

Kumar S, Chattopadhyay S, Sreejesh A et al (2015) Analysis of air permeability and WVTR characteristics of highly impermeable novel rubber nanocomposite. Mater Res Express 2:25001

Standard A (1989) Standard test methods for water vapor transmission of materials

Priyadarshi R, Kumar B, Negi YS (2018) Chitosan film incorporated with citric acid and glycerol as an active packaging material for extension of green chilli shelf life. Carbohydr Polym 195:329–338

Chen YR, Chen LH, Chang KS et al (2016) Structural characteristics and transport behavior of triptycene-based PIMs membranes: A combination study using ab initio calculation and molecular simulations. J Memb Sci 514:114–124

Kebria MRS, Rahimpour A, Bakeri G, Abedini R (2019) Experimental and theoretical investigation of thin ZIF-8/chitosan coated layer on air gap membrane distillation performance of PVDF membrane. Desalination 450:21–32

Pradhan AK, Swain SK (2012) Oxygen Barrier of Multiwalled Carbon Nanotube/Polymethyl Methacrylate Nanocomposites Prepared by in situ Method. J Mater Sci Technol 28:391–395

Recio R, Lozano AE, Prádanos P et al (2008) Effect of fractional free volume and Tg on gas separation through membranes made with different glassy polymers. J Appl Polym Sci 107:1039–1046

White RP, Lipson JEG (2016) Polymer free volume and its connection to the glass transition. Macromolecules 49:3987–4007

Acknowledgements

The first and second authors are thankful to MHRD for their fellowship. The first author is highly grateful to Mr. Mohd. Asif of NPL, Delhi, for their assistance in performing the test of electrical conductivity. US is also thankful to Ms. Vaishali Saroha, Rupam Gogoi, and Mr. Rahul Sharma of IIT Roorkee for their support.

Author information

Authors and Affiliations

Contributions

US was involved in conceptualization, methodology, investigation, and writing—original draft. SKS was involved in methodology, investigation, and writing—original draft. BPS was involved in MWCNT-synthesis, characterization-Raman spectroscopy, writing—review & editing. AK was involved in characterization-electrical conductivity, and writing—review & editing. GM was involved in conceptualization and writing—review & editing. AB was involved in conceptualization, project administration, funding acquisition, and writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Andrea de Camargo.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shankar, U., Sethi, S.K., Singh, B.P. et al. Optically transparent and lightweight nanocomposite substrate of poly(methyl methacrylate-co-acrylonitrile)/MWCNT for optoelectronic applications: an experimental and theoretical insight. J Mater Sci 56, 17040–17061 (2021). https://doi.org/10.1007/s10853-021-06390-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06390-3