Abstract

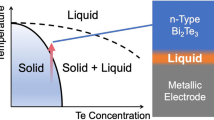

Bismuth telluride (BT) displays one of the highest thermoelectric performances between ambient temperature and 473 K. In general, although a thermoelectric material is connected to a metal electrode through soldering when thermoelectric modules are assembled, the solder components diffuse into the thermoelectric element at operating temperatures and under current stress. It is widely known that p-type bismuth telluride (p-BT) with a composition similar to that of Bi0.5Sb1.5Te3 includes a pure Te phase when the material is made using a melt growth process. Because the eutectic temperature of the pseudo-binary Bi0.5Sb1.5Te3–Te system is close to 693 K, a Te-rich liquid should be produced from p-BT at elevated temperatures above the eutectic point. It is possible for the produced liquid to be utilized as a flux to allow direct bonding between the metallic electrode material and p-BT without using solder. In this study, the reactivity between p-BT and selected metallic substrates (Cu, Ni, or 99.7 Ni–0.3 Cu (at.%)) was investigated at 773 K in an argon atmosphere, as a fundamental study of the joining process. Cu is strongly reactive to p-BT, whereas Ni has a modest reactivity against p-BT. Furthermore, the addition of a small amount of Cu to Ni drastically enhanced the diffusivity of Te in the Ni substrate. Our findings suggest that Cu addition plays a key role in controlling the reactivity, which is directly linked to the bonding strength, interfacial resistivity, and thermal stability.

Graphical abstract

Similar content being viewed by others

References

Yang L, Chen ZG, Dargusch MS, Zou J (2018) High performance thermoelectric materials: progress and their applications. Adv Energy Mater 8:1701797. https://doi.org/10.1002/aenm.201701797

Goldsmid HJ, Douglas RW (1954) The use of semiconductors in thermoelectric refrigeration. Br J Appl Phys 5:386–390. https://doi.org/10.1088/0508-3443/5/11/303

Satterthwaite CB, Ure RW (1957) Electrical and thermal properties of Bi2Te3. Phys Rev 108:1164–1170. https://doi.org/10.1103/PhysRev.108.1164

Goldsmid HJ (2014) Bismuth telluride and its alloys as materials for thermoelectric generation. Materials 7:2577–2592. https://doi.org/10.3390/ma7042577

Yim WM, Rosi FD (1972) Compound tellurides and their alloys for Peltier cooling - review. Solid State Electron 15:1121–1140. https://doi.org/10.1016/0038-1101(72)90172-4

Dresselhaus MS, Chen G, Tang MY, Yang RG, Lee H, Wang DZ, Ren ZF, Fleurial JP, Gogna P (2007) New directions for low-dimensional thermoelectric materials. Adv Mater 19:1043–1053. https://doi.org/10.1002/adma.200600527

Zhang QH, Huang XY, Bai SQ, Shi X, Uher C, Chen LD (2016) Thermoelectric devices for power generation: recent progress and future challenges. Adv Eng Mater 18:194–213. https://doi.org/10.1002/adem.201500333

Venkatasubramanian R, Siivola E, Colpitts T, O’Quinn B (2001) Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413:597–602. https://doi.org/10.1038/35098012

Poudel B, Hao Q, Ma Y, Lan YC, Minnich A, Yu B, Yan XA, Wang DZ, Muto A, Vashaee D, Chen XY, Liu JM, Dresselhaus MS, Chen G, Ren ZF (2008) High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320:634–638. https://doi.org/10.1126/science.1156446

Wu F, Song HZ, Gao F, Shi WY, Jia JF, Hu X (2013) Effects of different morphologies of Bi2Te3 nanopowders on thermoelectric properties. J Electron Mater 42:1140–1145. https://doi.org/10.1007/s11664-013-2541-z

Il Kim S, Lee KH, Mun HA, Kim HS, Hwang SW, Roh JW, Yang DJ, Shin WH, Li XS, Lee YH, Snyder GJ, Kim SW (2015) Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348:109–114. https://doi.org/10.1126/science.aaa4166

Snyder GJ, Toberer ES (2008) Complex thermoelectric materials. Nat Mater 7:105–114. https://doi.org/10.1038/nmat2090

Aswal DK, Basu R, Singh A (2016) Key issues in development of thermoelectric power generators: high figure-of-merit materials and their highly conducting interfaces with metallic interconnects. Energy Conv Manag 114:50–67. https://doi.org/10.1016/j.enconman.2016.01.065

Lan YC, Wang DZ, Chen G, Ren ZF (2008) Diffusion of nickel and tin in p-type (Bi, Sb)2Te3 and n-type Bi2(Te, Se)3 thermoelectric materials. Appl Phys Lett 92:101910. https://doi.org/10.1063/1.2896310

Chen SW, Wu CY, Wu HJ, Chiu WT (2014) Interfacial reactions in Sn/Bi2Te3, Sn/Bi2Se3, and Sn/Bi2(Te1-xSex)3 couples. J Alloy Compd 611:313–318. https://doi.org/10.1016/j.jallcom.2014.05.127

Lin CF, Hau NY, Huang YT, Chang YH, Feng SP, Chen CM (2017) Synergetic effect of Bi2Te3 alloys and electrodeposition of Ni for interfacial reactions at solder/Ni/Bi2Te3 joints. J Alloy Compd 708:220–230. https://doi.org/10.1016/j.jallcom.2017.02.300

Wang CH, Li MH, Chiu CW, Chang TY (2018) Kinetic study of solid-state interfacial reactions of p-type (Bi, Sb)2Te3 thermoelectric materials with Sn and Sn-Ag-Cu solders. J Alloy Compd 767:1133–1140. https://doi.org/10.1016/j.jallcom.2018.07.148

Liao CN, Chen WT, Lee CH (2010) Polarity effect on interfacial reactions at soldered junctions of electrically stressed thermoelectric modules. Appl Phys Lett 97:241906. https://doi.org/10.1063/1.3525930

Chan HT, Lin CF, Yen YW, Chen CM (2016) Effects of current stressing on the p-Bi2Te3/Sn interfacial reactions. J Alloy Compd 668:91–96. https://doi.org/10.1016/j.jallcom.2016.01.204

Hsu HH, Cheng CH, Lin YL, Chiou SH, Huang CH, Cheng CP (2013) Structural stability of thermoelectric diffusion barriers: experimental results and first principles calculations. Appl Phys Lett 103:053902. https://doi.org/10.1063/1.4817511

Tseng YC, Lee H, Hau NY, Feng SP, Chen CM (2018) Electrodeposition of Ni on Bi2Te3 and interfacial reaction between Sn and Ni-coated Bi2Te3. J Electron Mater 47:27–34. https://doi.org/10.1007/s11664-017-5777-1

Feng SP, Chang YH, Yang J, Poudel B, Yu B, Ren ZF, Chen G (2013) Reliable contact fabrication on nanostructured Bi2Te3-based thermoelectric materials. Phys Chem Chem Phys 15(18):6757–6762. https://doi.org/10.1039/c3cp50993a

Song ED, Swartzentruber BS, Koripella CR, Martinez JA (2019) Highly effective geni alloy contact diffusion barrier for BiSbTe long-term thermal exposure. ACS Omega 4:9376–9382. https://doi.org/10.1021/acsomega.9b00551

Wang CH, Hsieh HC, Lee HY, Wu AT (2019) Co-P diffusion barrier for p-Bi2Te3 thermoelectric material. J Electron Mater 48:53–57. https://doi.org/10.1007/s11664-018-6633-7

Cheng J, Hu X, Li Q (2020) Effects of the Ni electrodeposit on microstructure evolution and electrical resistance of the P-type Bi2Te3 solder joint. J Alloy Compd 832:155006. https://doi.org/10.1016/j.jallcom.2020.155006

Wang CH, Hsieh HC, Sun ZW, Ranganayakulu VK, Lan TW, Chen YY, Chang YY, Wu AT (2020) Interfacial stability in Bi2Te3 thermoelectric joints. ACS Appl Mater Interfaces 12:27001–27009. https://doi.org/10.1021/acsami.9b22853

Chen SW, Yang TR, Wu CY, Hsiao HW, Chu HS, Huang JD, Liou TW (2016) Interfacial reactions in the Ni/(Bi0.25Sb0.75)2Te3 and Ni/Bi2(Te0.9Se0.1)3 couples. J Alloy Compd 686:847–853. https://doi.org/10.1016/j.jallcom.2016.06.207

Chen SW, Liu ZW, Chu HS, Huang ZY (2018) Interfacial reactions between Ni and Bi2(Se0.1Te0.9)3 and its constituent material systems. J Alloy Compd 731:111–117. https://doi.org/10.1016/j.jallcom.2017.09.261

Weinstein M, Mlavsky AI (1962) Bonding of lead telluride to pure iron electrodes. Rev Sci Instrum 33:1119–1120. https://doi.org/10.1063/1.1717707

Mikami M, Kobayashi K, Kawada T, Kubo K, Uchiyama N (2008) Development and evaluation of high-strength Fe2VAl thermoelectric module. Jpn J Appl Phys 47:1512–1516. https://doi.org/10.1143/jjap.47.1512

Liu WS, Wang HZ, Wang LJ, Wang XW, Joshi G, Chen G, Ren ZF (2013) Understanding of the contact of nanostructured thermoelectric n-type Bi2Te2.7Se0.3 legs for power generation applications. J Mater Chem A 1:13093–13100. https://doi.org/10.1039/c3ta13456c

Xia HY, Drymiotis F, Chen CL, Wu AP, Snyder GJ (2014) Bonding and interfacial reaction between Ni foil and n-type PbTe thermoelectric materials for thermoelectric module applications. J Mater Sci 49:1716–1723. https://doi.org/10.1007/s10853-013-7857-9

Xia HY, Chen CL, Drymiotis F, Wu AP, Chen YY, Snyder GJ (2014) Interfacial reaction between Nb Foil and n-type PbTe thermoelectric materials during thermoelectric contact fabrication. J Electron Mater 43:4064–4069. https://doi.org/10.1007/s11664-014-3350-8

Li CC, Drymiotis F, Liao LL, Dai MJ, Liu CK, Chen CL, Chen YY, Kao CR, Snyder GJ (2015) Silver as a highly effective bonding layer for lead telluride thermoelectric modules assembled by rapid hot-pressing. Energy Conv Manag 98:134–137. https://doi.org/10.1016/j.enconman.2015.03.089

Xia HY, Drymiotis F, Chen CL, Wu AP, Chen YY, Snyder GJ (2015) Bonding and high-temperature reliability of NiFeMo alloy/n-type PbTe joints for thermoelectric module applications. J Mater Sci 50:2700–2708. https://doi.org/10.1007/s10853-015-8820-8

Yim WM, Fitzke EV, Rosi FD (1966) Thermoelectric properties of Bi2Te3-Sb2Te3-Sb2Se3 pseudo-ternary alloys in the temperature range 77 to 300 degrees K. J Mater Sci 1:52–65. https://doi.org/10.1007/bf00549720

Yim WM, Fitzke EV (1968) The effects of growth rate on the thermoelectric properties of Bi2Te3-Sb2Te3-Sb2Se3 pseudoternary alloys. J Electrochem Soc 115:556–560. https://doi.org/10.1149/1.2411329

Yamashita O, Tomiyoshi S (2003) Effect of annealing on thermoelectric properties of bismuth telluride compounds. Jpn J Appl Phys 42:492–500. https://doi.org/10.1143/jjap.42.492

Yamashita O, Sugihara S (2005) High-performance bismuth-telluride compounds with highly stable thermoelectric figure of merit. J Mater Sci 40:6439–6444. https://doi.org/10.1007/s10853-005-1712-6

Yamashita O, Tomiyoshi S, Makita K (2003) Bismuth telluride compounds with high thermoelectric figures of merit. J Appl Phys 93:368–374. https://doi.org/10.1063/1.1525400

Tashiro M, Sukenaga S, Ikemoto K, Shinoda K, Kajitani T, Suzuki S, Shibata H (2021) Investigation of interfacial reactions between metallic substrates and n-type bulk bismuth telluride thermoelectric material. J Mater Sci 56:14170–14180. https://doi.org/10.1007/s10853-021-06198-1

Tashiro M, Sukenaga S, Shibata H (2017) Control of crystallization behaviour of supercooled liquid composed of lithium disilicate on platinum substrate. Sci Rep 7:6078. https://doi.org/10.1038/s41598-017-06306-9

Mansour AN, Wong-Ng W, Huang Q, Tang W, Thompson A, Sharp J (2014) Structural characterization of Bi2Te3 and Sb2Te3 as a function of temperature using neutron powder diffraction and extended X-ray absorption fine structure techniques. J Appl Phys 116:083513. https://doi.org/10.1063/1.4892441

Adenis C, Langer V, Lindqvist O (1989) Reinvestigation of the structure of tellurium. Acta Crystallogr Sect C-Cryst Struct Commun 45:941–942. https://doi.org/10.1107/s0108270188014453

Hasezaki K, Hamachiyo T, Ashida M, Ueda T, Noda Y (2010) Thermoelectric properties and scattering factors of finely grained Bi2Te3-related materials prepared by mechanical alloying. Mater Trans 51:863–867. https://doi.org/10.2320/matertrans.MH200901

Caillat T, Carle M, Perrin D, Scherrer H, Scherrer S (1992) Study of the Bi-Sb-Te ternary phase diagram. J Phys Chem Solids 53:227–232. https://doi.org/10.1016/0022-3697(92)90049-j

Momma K, Izumi F (2011) VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Crystallogr 44(6):1272–1276. https://doi.org/10.1107/S0021889811038970

Thermophysical Properties Handbook (2008) Yokendo, Japan

Pavlova LM, Shtern YI, Mironov RE (2011) Thermal expansion of bismuth telluride. High Temp 49:369–379. https://doi.org/10.1134/s0018151x1103014x

Barin I (1989) Thermochemical data of pure substances. VCH, Weinheim, New York

Chen SW, Hutabalian Y, Hu ZK, Chen HH, Shih HW, Wang W (2020) Liquation phenomena in Sn/Bi2Te3, In/Bi2Te3 and Cu/Bi2Te3 couples. Acta Mater 196:418–429. https://doi.org/10.1016/j.actamat.2020.06.057

Nash P (1991) Phase diagrams of binary nickel alloys. Materials Park, OH: ASM International

Delatorre RG, Sartorelli ML, Schervenski AQ, Pasa AA, Guths S (2003) Thermoelectric properties of electrodeposited CuNi alloys on Si. J Appl Phys 93:6154–6158. https://doi.org/10.1063/1.1569432

Acknowledgements

This study was conducted under the “Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials” from the Ministry of Education, Culture, Sports, Science and Technology of Japan (MEXT). We thank Mr. Takashi Kamaya and Mr. Toshikatsu Terui (Tohoku University) for the EPMA analyses and for creating the alloy through arc melting, respectively. We are pleased to acknowledge the financial support by Panasonic Corporation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no competing financial interests.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Deceased: Tsuyoshi Kajitani

Rights and permissions

About this article

Cite this article

Tashiro, M., Sukenaga, S., Ikemoto, K. et al. Interfacial reactions between pure Cu, Ni, and Ni–Cu alloys and p-type Bi2Te3 bulk thermoelectric material. J Mater Sci 56, 16545–16557 (2021). https://doi.org/10.1007/s10853-021-06358-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06358-3