Abstract

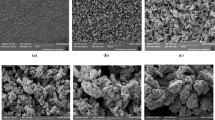

In this study, graphite/copper composites were prepared by microwave sintering. The microstructure and properties of the composites were characterized. The effects of different sintering temperatures on the properties of the composites were studied, and the differences between microwave sintering and conventional sintering composites were compared. The results show that after microwave sintering, the grain size of the copper matrix is refined and the graphite/copper interface is improved, and the distribution of graphite over the matrix becomes more uniform. Compared with conventional sintering, the properties of microwave-sintered samples have been further improved. Besides, with the increase in sintering temperature, the density, hardness, electrical conductivity and thermal conductivity of the composite have been improved, and some properties have become anisotropic obviously. Thus, the electrical conductivity and thermal conductivity along the direction of graphite sheet are higher than those perpendicular to the sheet.

Similar content being viewed by others

Data availability

The raw data and processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

The raw data and processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

Abbreviations

- CS:

-

Conventional sintering

- MS:

-

Microwave sintering

References

Liu B, Zhang DQ, Li XF, Guo XH, Shi J, Liu ZJ, Guo QG (2020) The microstructures and properties of graphite flake/copper composites with high volume fractions of graphite flake. New Carbon Mater 35(1):58–65

Zhu JM, Li JW, Liu T, Chen Z, Fang HC, Xiao P, Kong F (2020) Differences in mechanical behaviors and characteristics between natural graphite/copper composites and carbon-coated graphite/copper composites. Mater Charact 162:110195

Banerjee S, Pattnayek S, Kumar R, Kar KK (2020) Impact of graphite on thermomechanical, mechanical, thermal, electrical properties, and thermal conductivity of HDPE/copper composites. Fuel Cells 20(2):116–130

Jamwal A, Seth PP, Kumar D, Agrawal R, Sadasivuni KK, Gupta P (2020) Microstructural, tribological and compression behaviour of copper matrix reinforced with Graphite-SiC hybrid composites. Mater Chem Phys 251:123090

Zhang R, He XB, Chen Z, Qu XH (2017) Influence of Ti content on the microstructure and properties of graphite flake/Cu–Ti composites fabricated by vacuum hot pressing. Vacuum 141(7):265–271

Chen JH, Ren SB, He XB, Qu XH (2017) Properties and microstructure of nickel-coated graphite flakes/copper composites fabricated by spark plasma sintering. Carbon 121(9):25–34

Cao HJ, Tan ZQ, Fan GL, Guo Q, Su YS, Li ZQ, Xiong DB (2020) Wide and fine alignment control and interface modification for high-performance thermally conductive graphite/copper composite. Compos B Eng 191:107965

Jang JH, Park HK, Lee JH, Lim JW, Oh IH (2020) Effect of volume fraction and unidirectional orientation controlled graphite on thermal properties of graphite/copper composites. Compos B Eng 183:107735

Nazeer F, Ma Z, Gao LH, Wang FC, Khan MA, Malik A (2019) Thermal and mechanical properties of copper-graphite and copper-reduced graphene oxide composites. Compos B Eng 163:77–85

Tao ZC, Guo QG, Gao XQ, Liu L (2012) Graphite fiber/copper composites with near-zero thermal expansion. Mater Des 33(1):372–375

Abyzov AM, Kruszewski MJ, Ciupiński Ł, Mazurkiewicz M, Michalski A, Kurzydłowski KJ (2015) Diamond-tungsten based coating-copper composites with high thermal conductivity produced by pulse plasma sintering. Mater Des 76(7):97–109

Gao X, Yue HY, Guo E, Zhang H, Lin XY, Yao LH, Wang B (2016) Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites. Powder Technol 301(11):601–607

Che QL, Zhang JJ, Chen XK, Ji YQ, Li YW, Wang LX, Cao SZ, Guo L, Wang Z, Wang SW, Zhang ZK, Jiang YG (2015) Spark plasma sintering of titanium-coated diamond and copper-titanium powder to enhance thermal conductivity of diamond/copper composites. Mater Sci Semicond Process 33(5):67–75

Wejrzanowski T, Grybczuk M, Chmielewski M, Pietrzak K, Kurzydlowski KJ, Strojny-Nedza A (2016) Thermal conductivity of metal-graphene composites. Mater Des 99(6):163–173

Bai H, Xue C, Lyu JL, Li J, Chen GX, Yu JH, Lin CT, Lv DJ, Xiong LM (2018) Thermal conductivity and mechanical properties of flake graphite/copper composite with a boron carbide-boron nano-layer on graphite surface. Compos Part A Appl Sci Manuf 106(3):42–51

Chu K, Wang F, Wang XH, Li YB, Geng ZR, Huang DJ, Zhang H (2018) Interface design of graphene/copper composites by matrix alloying with titanium. Mater Des 144:290–303

Xue C, Bai H, Tao PF, Wang JW, Jiang N, Wang SL (2016) Thermal conductivity and mechanical properties of flake graphite/Al composite with a SiC nanolayer on graphite surface. Mater Des 108(100):250–258

Zweben C (1998) Advances in composite materials for thermal management in electronic packaging. JOM 50(6):47–51

Koráb J, Štefánik P, Kavecký Š, Šebo P, Korb G (2002) Thermal conductivity of unidirectional copper matrix carbon fibre composites. Compos Part A Appl Sci Manuf 33(4):577–581

Liu Q, He XB, Ren SB, Zhang C, Liu TT, Qu XH (2014) Thermophysical properties and microstructure of graphite flake/copper composites processed by electroless copper coating. J Alloys Compd 587:255–259

Guo SJ, Yang QS, He XQ, Liew KM (2014) Modeling of interface cracking in copper–graphite composites by MD and CFE method. Compos B Eng 58:586–592

Li JF, Cheng JG, Chen PQ, Chen WC, Wei BZ, Liu JW (2018) Effects of partial substitution of copper for cobalt on the microstructure and properties of ultrafine-grained WC–Co cemented carbides. J Alloys Compd 735:43–50

Hou M, Guo SH, Yang L, Gao JY, Peng JH, Hu T, Wang L, Ye XL (2018) Fabrication of Fe–Cu matrix diamond composite by microwave hot pressing sintering. Powder Technol 338:36–43

El Khaled D, Novas N, Gazquez JA, Manzano-Agugliaro F (2018) Microwave dielectric heating: Applications on metals processing. Renew Sustain Energy Rev 82:2880–2892

Penchal Reddy M, Ubaid F, Shakoor RA, Mohamed AMA (2018) Microstructure and mechanical behavior of microwave sintered Cu50Ti50 amorphous alloy reinforced Al metal matrix composites. JOM 70(6):817–822

Pan HL, Xing CF, Bi JX, Jiang XS, Mao YX, Wu HT (2016) Sintering characteristics and microwave dielectric properties of low loss MgZrNb2O8 ceramics achieved by reaction sintering process. J Alloys Compd 687:274–279

Feng ZB, Xing CF, Bi JX, Jiang XS, Wu HT (2016) Sintering characteristics and microwave dielectric properties of low loss CoZrNb2O8 ceramics achieved by reaction sintering process. J Alloys Compd 686:923–929

Manière C, Lee G, Zahrah T, Olevsky EA (2018) Microwave flash sintering of metal powders: from experimental evidence to multiphysics simulation. Acta Mater 147:24–34

Mondal A, Upadhyaya A, Agrawal D (2010) Effect of heating mode on sintering of tungsten. Int J Refract Met Hard Mat 28(5):597–600

Kawk SR, Ring TA, Choi BS (2019) A simple two-step fabrication route for Cu composite reinforced by three-dimensional graphene network. J Ind Eng Chem 70:484–488

Upadhyaya A, Tiwari SK, Mishra P (2007) Microwave sintering of W–Ni–Fe alloy. Scr Mater 56(1):5–8

Mahadevan S, Chauhan APS (2016) Investigation of synthesized nanosized copper by polyol technique with graphite powder. Adv Powder Technol 27(4):1852–1856

Zhang R, He XB, Chen HT, Qu XH (2019) Effect of alloying element Zr on the microstructure and properties of graphite flake/Cu composites fabricated by vacuum hot pressing. J Alloys Compd 770:267–275

Hernández JLR, Cruz JJR, Gómez CY, Coreño OA, Martínez-Sanchez R (2010) Synthesis of graphite reinforced aluminum nanocomposite by mechanical alloying. Mater Trans 51(6):1120–1126

Wang YR, Gao YM, Li YF, Zhang C, Sun L, Zhai WY (2017) Research on nickel modified graphite/Cu composites interface. Surf Coat Technol 328:70–79

Sohn YH, Han T, Han JH (2019) Effects of shape and alignment of reinforcing graphite phases on the thermal conductivity and the coefficient of thermal expansion of graphite/copper composites. Carbon 149:152–164

Boden A, Boerner B, Kusch P, Firkowska I, Reich S (2014) Nanoplatelet size to control the alignment and thermal conductivity in copper–graphite composites. Nano Lett 14(6):3640–3644

Kumar J, Mondal S (2018) Microstructure and properties of graphite-reinforced copper matrix composites. J Braz Soc Mech Sci Eng 40(4):196

Kong B, Fan TX, Ru JM (2016) Improved wetting and thermal properties of graphite–Cu composite by Cr-solution immersion method. Diam Relat Mat 65:191–197

Fan XL, Huang XW, Liu Q, Li MM, Wang JF, Ding HM (2019) In-situ synthesis of ZrC in Cu melts using the graphite as the source of C. Vacuum 164:198–204

Rajkumar K, Aravindan S (2009) Microwave sintering of copper–graphite composites. J Mater Process Technol 209(15–16):5601–5605

C Ayyappadas, OS Shanu, A Vijayan, MA Irfan, V Vishnu, M Shamnadh (2019) Effect of graphene, SiC and graphite addition on hardness, microstructure and electrical conductivity of microwave sintered copper MMCs fabricated by powder metallurgy route. In: International Conference on Aerospace and Mechanical Engineering, T K M College of Engineering, Kerala, India, 17–19 Dec 2018, 1355(1):012035

Brandon D, Kaplan W (2008) Microstructural characterization of materials, 2nd edn. Haifa, Israel

Kováčik J, Emmer Š (2019) Cross property connection between the electric and the thermal conductivities of copper graphite composites. Int J Eng Sci 144:103130

Cheng JJ, Gan XP, Chen SQ, Lai YT, Xiong HW, Zhou KC (2019) Properties and microstructure of copper/nickel-iron-coated graphite composites prepared by electroless plating and spark plasma sintering. Powder Technol 343:705–713

López GA, Mittemeijer EJ (2004) The solubility of C in solid Cu. Scr Mater 51(1):1–5

Molina JM, Louis E (2015) Anisotropy in thermal conductivity of graphite flakes-SiCp/matrix composites: implications in heat sinking design for thermal management applications. Mater Charact 109:107–115

Zhao Y, Ren SB, Liu Q, Chen JH, He XB, Qu XH (2020) Effect of boron on the microstructure and properties of graphite flakes/copper composites fabricated by vacuum hot pressing. J Alloys Compd 815:152425

Liu Q, Zhang C, Cheng JJ, Wang F, Lv Z, Liu Y, Qu XH (2019) Modeling of interfacial design and thermal conductivity in graphite flake/Cu composites for thermal management application. Appl Therm Eng 156:351–358

Demirskyi D, Agrawala D, Ragulya A (2010) Neck growth kinetics during microwave sintering of copper. Scr Mater 62(8):552–555

Bao R, Yi JH (2014) Densification and alloying of microwave sintering WC-8 wt%Co composites. Int J Refract Met Hard Mater 43:269–275

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51864030), National Key R&D Program of China (No. 2018YFC1901904), Yunnan Provincial Science and Technology Talents Program (No. 2019HB003), Yunnan Science and Technology Major Project (Grant Nos. 2019ZE001 and 2018ZE027), Yunnan Provincial youth Top-notch Talent Support Program, and Scientific Research Fund of Kunming University of Science and Technology (Grant Nos. KKZ3201752046 and KKSY201732033).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Kevin Jones.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Z., Xu, L., Peng, J. et al. Effect of the microstructure and properties of graphite/copper composites fabricated by microwave sintering. J Mater Sci 56, 9183–9195 (2021). https://doi.org/10.1007/s10853-021-05891-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05891-5