Abstract

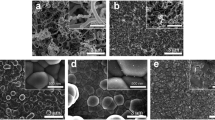

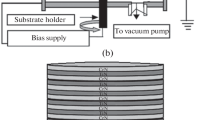

Stainless-steel bipolar plates (BPPs) are of great significance in low-cost, easily processable, lightweight proton exchange membrane fuel cells (PEMFCs) despite the challenge presented by corrosion in protective coatings. Localized corrosion along the grain boundaries in a crystal film is common, but few preventive measures have been developed so far. Thus, we propose a novel strategy using a tantalum (Ta) and carbon (C) co-modification to improve the chemical stability of titanium carbide (TiC)-based coatings (Cr/Ta/TiC/C). During the film growth, the subjacent Ta atoms were thermally diffused throughout the columnar structure of TiC and reacted with the C layer. The reaction product, i.e., TaC, acted as a chemical passivator to the grain boundary. Combined with the C capping layer, these functional layers synergistically suppressed any localized corrosion. Therefore, corrosion current densities within the United States Department of Energy’s technical recommendations were achieved in both potentiostatic and potentiodynamic polarization. Meanwhile, by controlling the Ta metal dispersion, the interfacial contact resistance between the multilayer structure and the carbon paper can be reduced to 7.1 mΩ·cm−2 at a compaction force of 140 N·cm−2. The substantial improvement in the corrosion resistance and conductivity of BPP places our work among the most efficient anticorrosion systems in PEMFC applications reported so far.

Similar content being viewed by others

References

Lv JL, Wang ZQ, Liang TX, Ken S, Hideo M (2017) Enhancing the corrosion resistance of the 2205 duplex stainless steel bipolar plates in PEMFCs environment by surface enriched molybdenum. Results Phys 7:3459–3464. https://doi.org/10.1016/j.rinp.2017.09.001

Mandal P, Chanda UK, Roy S (2018) A review of corrosion resistance method on stainless steel bipolar plate. Mater Today-Proc 5:17852–17856. https://doi.org/10.1016/j.matpr.2018.06.111

Sievers GW, Anklam K, Henkel R, Hickmann T, Bruser V (2019) Corrosion-protection of moulded graphite conductive plastic bipolar plates in PEM electrolysis by plasma processing. Int J Hydrogen Energ 44:2435–2445. https://doi.org/10.1016/j.ijhydene.2018.12.020

Tawfik H, Hung Y, Mahajan D (2007) Metal bipolar plates for PEM fuel cell–a review. J Power Sources 163:755–767. https://doi.org/10.1016/j.jpowsour.2006.09.088

Asri NF, Husaini T, Sulong A, Majlan EH, Daud WRW (2017) Coating of stainless steel and titanium bipolar plates for anticorrosion in PEMFC: A review. Int J Hydrogen Energ 42:9135–9148. https://doi.org/10.1016/j.ijhydene.2016.06.241

Wang LX, Sun JC, Kang B, Li S, Ji SJ, Wen ZS et al (2014) Electrochemical behaviour and surface conductivity of niobium carbide-modified austenitic stainless steel bipolar plate. J Power Sources 246:775–782. https://doi.org/10.1016/j.jpowsour.2013.08.025

Shi K, Li X, Zhao Y, Li WW, Wang SB, Xie XF et al (2019) Corrosion behavior and conductivity of TiNb and TiNbN coated Steel for metallic bipolar plates. Appl Sci-Basel 9:2568. https://doi.org/10.3390/app9122568

Xu J, Huang HJ, Li ZY, Xu S, Tao HL, Munroe P et al (2016) Corrosion behavior of a ZrCN coated Ti alloy with potential application as a bipolar plate for proton exchange membrane fuel cell. J Alloy Compd 663:718–730. https://doi.org/10.1016/j.jallcom.2015.12.197

Dadfar M, Salehi M, Golozar MA, Trasatti S, Casaletto MP (2017) Surface and corrosion properties of modified passive layer on 304 stainless steel as bipolar plates for PEMFCs. Int J Hydrogen Energ 42:25869–25876. https://doi.org/10.1016/j.ijhydene.2017.08.169

Dadfar M, Salehi M, Golozar MA, Trasatti S (2016) Surface modification of 304 stainless steels to improve corrosion behavior and interfacial contact resistance of bipolar plates. Int J Hydrogen Energ 41:21375–21384. https://doi.org/10.1016/j.ijhydene.2016.09.149

Stoot AC, Camilli L, Spiegelhauer SA, Yu F, Boggild P (2015) Multilayer graphene for long-term corrosion protection of stainless steel bipolar plates for polymer electrolyte membrane fuel cell. J Power Sour 293:846–851. https://doi.org/10.1016/j.jpowsour.2015.06.009

Zhao Y, Wei L, Yi PY, Peng LF (2016) Influence of Cr-C film composition on electrical and corrosion properties of 316L stainless steel as bipolar plates for PEMFCs. Int J Hydrogen Energ 41:1142–1150. https://doi.org/10.1016/j.ijhydene.2015.10.047

Ren YJ, Zeng CL (2007) Corrosion protection of 304 stainless steel bipolar plates using TiC films produced by high-energy micro-arc alloying process. J Power Sour 171:778–782. https://doi.org/10.1016/j.jpowsour.2007.06.075

Park YC, Lee SH, Kim SK, Lim S, Jung DH, Park KB et al (2011) Corrosion properties and cell performance of CrN/Cr-coated stainless steel 316L as a metal bipolar plate for a direct methanol fuel cell. Electrochim Acta 56:7602–7609. https://doi.org/10.1016/j.electacta.2011.06.080

Yi PY, Zhang WX, Bi FF, Peng LF, Lai XM (2019) Microstructure and properties of a-C films deposited under different argon flow rate on stainless steel bipolar plates for proton exchange membrane fuel cells. J Power Sour 410:188–195. https://doi.org/10.1016/j.jpowsour.2018.10.054

Fukutsuka T, Yamaguchi T, Miyano SI, Matsuo Y, Sugie Y, Ogumi Z (2007) Carbon-coated stainless steel as PEFC bipolar plate material. J Power Sour 174:199–205. https://doi.org/10.1016/j.jpowsour.2007.08.096

Lee YB, Lee CH, Lim DS (2009) The electrical and corrosion properties of carbon nanotube coated 304 stainless steel/polymer composite as PEM fuel cell bipolar plates. Int J Hydrogen Energ 34:9781–9787. https://doi.org/10.1016/j.ijhydene.2009.08.065

Li R, Cai Y, Wippermann K, Lehnert W (2019) Bilayer CrN/Cr coating-modified 316L stainless steel bipolar plates for high temperature polymer electrolyte fuel cells. J Power Sour 434:226718. https://doi.org/10.1016/j.jpowsour.2019.226718

Hu YQ, Chen F, Xiang ZD (2019) Cr2N coated martensitic stainless steels by pack cementation process as materials for bipolar plates of proton exchange membrane fuel cells. J Power Sour 414:167–173. https://doi.org/10.1016/j.jpowsour.2019.01.002

Lu JL, Abbas N, Tang JN, Hu RT, Zhu GM (2019) Characterization of Ti3SiC2-coating on stainless steel bipolar plates in simulated proton exchange membrane fuel cell environments. Electrochem Commun 105:106490. https://doi.org/10.1016/J.Elecom.2019.106490

Wang L, Tao YK, Zhang Z, Wang YJ, Feng Q, Wang HJ et al (2019) Molybdenum carbide coated 316L stainless steel for bipolar plates of proton exchange membrane fuel cells. Int J Hydrogen Energ 44:4940–4950. https://doi.org/10.1016/j.ijhydene.2018.12.184

Pei YT, Galvan D, De Hosson JTM (2005) Nanostructure and properties of TiC/a-C: H composite coatings. Acta Mater 53:4505–4521. https://doi.org/10.1016/j.actamat.2005.05.045

Wang SL, Hou M, Zhao Q, Jiang YY, Wang Z, Li HZ et al (2017) Ti/(Ti, Cr)N/CrN multilayer coated 316L stainless steel by arc ion plating as bipolar plates for proton exchange membrane fuel cells. J Energy Chem 26:168–174. https://doi.org/10.1016/j.jechem.2016.09.004

Jannat S, Rashtchi H, Atapour M, Golozar MA, Elmkhah H, Zhiani M (2019) Preparation and performance of nanometric Ti/TiN multi-layer physical vapor deposited coating on 316L stainless steel as bipolar plate for proton exchange membrane fuel cells. J Power Sour 435:226818. https://doi.org/10.1016/j.jpowsour.2019.226818

Wan ZX, Zhang TF, Lee HBR, Yang JH, Choi WC, Han B et al (2015) Improved corrosion resistance and mechanical properties of CrN hard coatings with an atomic Layer deposited Al2O3 inter layer. ACS Appl Mater Inter 7:26716–26725. https://doi.org/10.1021/acsami.5b08696

Zhu SF, Wu YP, Liu TW, Tang K, Wei Q (2013) Interface structure and corrosion resistance of Ti/Cr nanomultilayer film prepared by magnetron sputtering on depleted uranium. ACS Appl Mater Inter 5:6598–6602. https://doi.org/10.1021/am401284e

Yi PY, Peng LF, Zhou T, Wu H, Lai XM (2013) Development and characterization of multilayered Cr-C/a-C: Cr film on 316L stainless steel as bipolar plates for proton exchange membrane fuel cells. J Power Sour 230:25–31. https://doi.org/10.1016/j.jpowsour.2012.11.063

PY Yi, WX Zhang, FF Bi, LF Peng, XM Lai 2018 Enhancedcorrosion resistance and interfacial conductivity of TiCx/a-C nanolayered coatings via synergy of substrate bias voltage for bipolar plates applications in PEMFCs. Mater Inter ACS Appl 10(22): 19087-96 10 19087-1909610.1021/acsami.8b00514

Wang HL, Sweikart MA, Turner JA (2003) Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sour 115:243–251. https://doi.org/10.1016/S0378-7753(03)00023-5

Soucek P, Schmidtova T, Zabransky L, Bursikova V, Vasina P, Caha O et al (2014) On the control of deposition process for enhanced mechanical properties of nc-TiC/a-C: H coatings with DC magnetron sputtering at low or high ion flux. Surf Coat Tech 255:8–14. https://doi.org/10.1016/j.surfcoat.2013.11.001

Pei YT, Chen CQ, Shaha KP, De Flosson JTM, Bradley JW, Voronin SA et al (2008) Microstructural control of TiC/a-C nanocomposite coatings with pulsed magnetron sputtering. Acta Mater 56:696–709. https://doi.org/10.1016/j.actamat.2007.10.025

Galvan D, Pei YT, De Hosson JTM (2005) TEM characterization of a Cr/Ti/TiC graded interlayer for magnetron-sputtered TiC/a-C: H nanocomposite coatings. Acta Mater 53:3925–3934. https://doi.org/10.1016/j.actamat.2005.04.040

Cho KH, Lee WG, Lee SB, Jang H (2008) Corrosion resistance of chromized 316L stainless steel for PEMFC bipolar plates. J Power Sour 178:671–676. https://doi.org/10.1016/j.jpowsour.2007.09.031

Lohse BH, Calka A, Wexler D (2005) Raman spectroscopy as a tool to study TiC formation during controlled ball milling. J Appl Phys 97:114912. https://doi.org/10.1063/1.1927282

Zhang LH, Koka RV (1998) A study on the oxidation and carbon diffusion of TiC in alumina titanium carbide ceramics using XPS and Raman spectroscopy. Mater Chem Phys 57:23–32. https://doi.org/10.1016/S0254-0584(98)00187-4

Nieto A, Lahiri D, Agarwal A (2013) Graphene NanoPlatelets reinforced tantalum carbide consolidated by spark plasma sintering. Mat Sci Eng a-Struct 582:338–346. https://doi.org/10.1016/j.msea.2013.06.006

Han JX, Zhang HB, Sun JC, Zhao WY, Cui JL (2019) Effect of diffusion alloying time on corrosion resistance and surface conductivity of niobium-alloying-modified AISI430 stainless steel for DFAFC bipolar plate. Anti-Corros Method M 66:222–229. https://doi.org/10.1108/Acmm-08-2018-1982

Feng K, Cai X, Sun HL, Li ZG, Chu PK (2010) Carbon coated stainless steel bipolar plates in polymer electrolyte membrane fuel cells. Diam Relat Mater 19:1354–1361. https://doi.org/10.1016/j.diamond.2010.07.003

Bojinov M, Fahricius G, Laitinen T, Makela K, Saario T, Sundholm G (1999) Conduction mechanism of the anodic film on Fe-Cr alloys in sulfate solutions. J Electrochem Soc 146:3238–3247. https://doi.org/10.1149/1.1392461

Andre J, Antoni L, Petit JP (2010) Corrosion resistance of stainless steel bipolar plates in a PEFC environment: A comprehensive study. Int J Hydrogen Energ 35:3684–3697. https://doi.org/10.1016/j.ijhydene.2010.01.062

Gileadi E, Kirowa-Eisner E (2005) Some observations concerning the Tafel equation and its relevance to charge transfer in corrosion. Corros Sci 47:3068–3085. https://doi.org/10.1016/j.corsci.2005.05.044

Choi HC, Jung YM, Kim SB (2005) Size effects in the Raman spectra of TiO2 nanoparticles. Vib Spectrosc 37:33–38. https://doi.org/10.1016/j.vibspec.2004.05.006

Xu CY, Zhang PX, Yan L (2001) Blue shift of Raman peak from coated TiO2 nanoparticles. J Raman Spectrosc 32:862–865. https://doi.org/10.1002/Jrs.773

Zhang WF, He YL, Zhang MS, Yin Z, Chen Q (2000) Raman scattering study on anatase TiO2 nanocrystals. J Phys D Appl Phys 33:912–916. https://doi.org/10.1088/0022-3727/33/8/305

Feng K, Li ZG, Sun HL, Yu L, Cai X, Wu YX et al (2013) C/CrN multilayer coating for polymer electrolyte membrane fuel cell metallic bipolar plates. J Power Sour 222:351–358. https://doi.org/10.1016/j.jpowsour.2012.08.087

Xu J, Li ZY, Xu S, Munroe P, Xie ZH (2015) A nanocrystalline zirconium carbide coating as a functional corrosion-resistant barrier for polymer electrolyte membrane fuel cell application. J Power Sour 297:359–369. https://doi.org/10.1016/j.jpowsour.2015.08.024

Lee S, Woo S, Kakati N, Lee Y, Yoon Y (2016) Corrosion and electrical properties of carbon/ceramic multilayer coated on stainless steel bipolar plates. Surf Coat Tech 303:162–169. https://doi.org/10.1016/j.surfcoat.2016.03.072

Wang HC, Sheu HH, Lu CE, Hou KH, Ger MD (2015) Preparation of corrosion-resistant and conductive trivalent Cr-C coatings on 304 stainless steel for use as bipolar plates in proton exchange membrane fuel cells by electrodeposition. J Power Sour 293:475–483. https://doi.org/10.1016/j.jpowsour.2015.05.105

Acknowledgement

This work is supported by the National Natural Science Foundation of China (No. 51902054 and No. 51702051) and Natural Science Foundation of Guangdong province (Grant No. 2017A030313307).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, J., Xu, Z., Li, Y. et al. Intergranular passivation of the TiC coating for enhancing corrosion resistance and surface conductivity in stainless-steel bipolar plates. J Mater Sci 56, 8689–8703 (2021). https://doi.org/10.1007/s10853-020-05733-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05733-w