Abstract

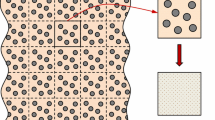

A micromechanical simulation has been performed to study the effect of particle distribution on the mechanical properties and damage behaviors of particle reinforced metal matrix composites (PRMMCs). Two-dimensional (2D) representative volume elements with variable particle size, volume fraction and particle distribution were generated and subjected to finite element simulation. An enhanced continuum model, which incorporates dislocation punching effect at particle-matrix interfaces and Taylor-based nonlocal theory of plasticity in matrix, was used to simulate the mismatch in coefficients of thermal expansion strengthening and particle size-dependent strengthening. Additionally, constitutive damage behaviors were involved in simulating the crack initiation and evolution, considering the ductile damage in matrix and dislocation punching zone, as well as the particle cracking. Simulation results indicate that refining the particle size is helpful to improve the tensile strength and fracture resistance of PRMMCs, whereas the increase of particle clustering volume fraction or severity facilitates damage evolution and deteriorates the mechanical properties. Statistical analysis indicates a negative linear dependence between particle distribution homogeneity and the ductility, given a constant particle size and volume fraction.

Graphical abstract

Similar content being viewed by others

References

Miracle DB (2005) Metal matrix composites – from science to technological significance. Compos Sci Technol 65:2526–2540. https://doi.org/10.1016/j.compscitech.2005.05.027

Tjong SC, Ma ZY (2000) Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng R 29:49–113

Kainer KU (2006) Metal matrix composites: custom-made materials for automotive and aerospace engineering. John Wiley, Hoboken

Lloyd DJ (1994) Particle reinforced aluminium and magnesium matrix composites. Int Mater Rev 39:1–23. https://doi.org/10.1179/imr.1994.39.1.1

Chawla N, Shen Y (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3:357–370

Qing H (2013) 2D micromechanical analysis of SiC/Al metal matrix composites under tensile, shear and combined tensile/shear loads. Mater Des 51:438–447. https://doi.org/10.1016/j.matdes.2013.04.051

Mcwilliams BA, Ramesh KT, Yen C (2013) Probabilistic response of heterogeneous particle reinforced metal matrix composites with particle size dependent strengthening. Comput Mater Sci 79:15–24. https://doi.org/10.1016/j.commatsci.2013.05.047

Yuan Z, Li F, Xue F et al (2014) Analysis of the stress states and interface damage in a particle reinforced composite based on a micromodel using cohesive elements. Mater Sci Eng A 589:288–302. https://doi.org/10.1016/j.msea.2013.09.097

Zhang J, Ouyang Q, Guo Q et al (2016) 3D Microstructure-based finite element modeling of deformation and fracture of SiCp/Al composites. Compos Sci Technol 123:1–9. https://doi.org/10.1016/j.compscitech.2015.11.014

Sung Y, Joshi SP, Ramesh KT (2009) An enhanced continuum model for size-dependent strengthening and failure of particle-reinforced composites. Acta Mater 57:5848–5861. https://doi.org/10.1016/j.actamat.2009.08.010

Eckschlager A, Han W (2002) A unit cell model for brittle fracture of particles embedded in a ductile matrix. Comput Mater Sci 25:85–91

Ma S, Zhuang X, Wang X (2019) 3D micromechanical simulation of the mechanical behavior of an in-situ Al3Ti/A356 composite. Compos Part B Eng 176:107115

Qing H (2013) Automatic generation of 2D micromechanical finite element model of silicon – carbide/aluminum metal matrix composites: effects of the boundary conditions. Mater Des 44:446–453. https://doi.org/10.1016/j.matdes.2012.08.011

Kanit T, Forest S, Galliet I et al (2003) Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int J Solids Struct 40:3647–3679. https://doi.org/10.1016/S0020-7683(03)00143-4

Jagadeesh GV, Setti SG (2020) A review on micromechanical methods for evaluation of mechanical behavior of particulate reinforced metal matrix composites. J Mater Sci 55:9848–9882. https://doi.org/10.1007/s10853-020-04715-2

Meng Q, Wang Z (2015) Prediction of interfacial strength and failure mechanisms in particle-reinforced metal-matrix composites based on a micromechanical model. Eng Fract Mech 142:170–183. https://doi.org/10.1016/j.engfracmech.2015.06.001

Kang G, Shao X, Guo S (2008) Effect of interfacial bonding on uniaxial ratchetting of SiCP/6061Al composites: finite element analysis with 2-D and 3-D unit cells. Mater Sci Eng A 487:431–444

Segurado J, Llorca J (2005) A computational micromechanics study of the effect of interface decohesion on the mechanical behavior of composites. Acta Mater 53:4931–4942. https://doi.org/10.1016/j.actamat.2005.07.013

Chawla N, Ganesh VV, Wunsch B (2004) Three-dimensional (3D) microstructure visualization and finite element modeling of the mechanical behavior of SiC particle reinforced aluminum composites. Scr Mater 51:161–165. https://doi.org/10.1016/j.scriptamat.2004.03.043

Voituriez C, Hall IW (1991) Strengthening mechanisms in whisker-reinforced aluminium composites. J Mater Sci 26:4241–4249. https://doi.org/10.1007/BF02402975

Wu Y, Lavernia EJ (1992) Strengthening behavior of particulate reinforced MMCs. Scr Metall Mater 27:173–178

Shao JC, Xiao BL, Wang QZ et al (2011) An enhanced FEM model for particle size dependent flow strengthening and interface damage in particle reinforced metal matrix composites. Compos Sci Technol 71:39–45. https://doi.org/10.1016/j.compscitech.2010.09.014

Gao X, Zhang X, Li A, Geng L (2020) Plastic deformation and fracture behaviors in particle-reinforced aluminum composites: a numerical approach using an enhanced finite element model. J Compos Mater 54:1977–1985

Dai LH, Ling Z, Bai YL (2001) Size-dependent inelastic behavior of particle-reinforced metal-matrix composites. Compos Sci Technol 61:1057–1063

Arsenault RJ, Shi N (1986) Dislocation generation due to differences between the coefficients of thermal expansion. Mater Sci Eng 81:175–187

Shibata S, Taya M, Mori T, Mura T (1992) Dislocation punching from spherical inclusions in a metal matrix composite. Acta Metall Mater 40:3141–3148

Gao H, Huang Y, Nix WD, Hutchinson JW (1999) Mechanism-based strain gradient plasticity—I. Theory. J Mech Phys Solids 47:1239–1263

Huang Y, Qu S, Hwang KC et al (2004) A conventional theory of mechanism-based strain gradient plasticity. Int J Plast 20:753–782

Qu S, Siegmund T, Huang Y (2005) A study of particle size effect and interface fracture in aluminum alloy composite via an extended conventional theory of mechanism-based strain-gradient plasticity. Compos Sci Technol 65:1244–1253. https://doi.org/10.1016/j.compscitech.2004.12.029

Weng L, Fan T, Wen M, Shen Y (2019) Three-dimensional multi-particle FE model and effects of interface damage, particle size and morphology on tensile behavior of particle reinforced composites. Compos Struct 209:590–605

Gao H, Huang Y (2001) Taylor-based nonlocal theory of plasticity. Int J Solids Struct 38:2615–2637

Dastgerdi JN, Anbarlooie B, Miettinen A et al (2018) Effects of particle clustering on the plastic deformation and damage initiation of particulate reinforced composite utilizing X-ray CT data and finite element modeling. Compos Part B 153:57–69. https://doi.org/10.1016/j.compositesb.2018.07.027

Yu M, Zhu P, Ma Y (2013) Effects of particle clustering on the tensile properties and failure mechanisms of hollow spheres filled syntactic foams: a numerical investigation by microstructure based modeling. Mater Des 47:80–89. https://doi.org/10.1016/j.matdes.2012.12.004

Llorca J, Segurado J, Gonza C (2003) A numerical investigation of the effect of particle clustering on the mechanical properties of composites. Acta Mater 51:2355–2369. https://doi.org/10.1016/S1359-6454(03)00043-0

Sun Y, Zhao Y, Wu J et al (2020) Effects of particulate agglomerated degree on deformation behaviors and mechanical properties of in-situ ZrB2 nanoparticles reinforced AA6016 matrix composites by finite element modeling. Mater Res Express 7:36507

Hu X, Wilkinson DS, Jain M, Mishra RK (2007) Modeling the influence of grain-level matrix inhomogeneity on strain localization in the presence of hard particles. Model Simul Mater Sci Eng 15:893–909

Liu Q, Qi F, Ding H et al (2018) Distribution of stress and strain between adjacent particles in particulate reinforced metal matrix composites. Trans Nonferrous Met Soc China 28:2314–2323. https://doi.org/10.1016/S1003-6326(18)64876-9

Abedini A, Butcher C, Chen ZT (2013) Numerical simulation of the influence of particle clustering on tensile behavior of particle-reinforced composites. Comput Mater Sci 73:15–23. https://doi.org/10.1016/j.commatsci.2013.02.021

Shehata MT, Boyd JD (1988) Measurement of spatial distribution of inclusions. In: Rungta R (ed) Inclusions and their influence on materials behavior. ASM International, Metals Park, OH, pp 123–131

Bertram M, Wendrock H (1996) Characterization of planar local arrangement by means of the Delaunay neighbourhood. J Microsc 181:45–53

Yang N, Boselli J, Sinclair I (2001) Simulation and quantitative assessment of homogeneous and inhomogeneous particle distributions in particulate metal matrix composites. J Microsc 201:189–200

Ayyar A, Crawford GA, Williams JJ, Chawla N (2008) Numerical simulation of the effect of particle spatial distribution and strength on tensile behavior of particle reinforced composites. Comput Mater Sci 44:496–506. https://doi.org/10.1016/j.commatsci.2008.04.009

Deng X, Chawla N (2006) Modeling the effect of particle clustering on the mechanical behavior of SiC particle reinforced Al matrix composites. J Mater Sci. https://doi.org/10.1007/s10853-006-0100-1

Wang D, Shanthraj P, Springer H, Raabe D (2018) Particle-induced damage in Fe-TiB2 high stiffness metal matrix composite steels. Mater Des 160:557–571. https://doi.org/10.1016/j.matdes.2018.09.033

Vajragupta N, Uthaisangsuk V, Schmaling B et al (2012) A micromechanical damage simulation of dual phase steels using XFEM. Comput Mater Sci 54:271–279. https://doi.org/10.1016/j.commatsci.2011.10.035

Tursun G, Weber U, Soppa E, Schmauder S (2006) The influence of transition phases on the damage behaviour of an Al/10vol.%SiC composite. Comput Mater Sci 37:119–133. https://doi.org/10.1016/j.commatsci.2005.12.018

Zhang JF, Zhang XX, Wang QZ et al (2018) Simulations of deformation and damage processes of SiCp/Al composites during tension. J Mater Sci Technol 34:627–634. https://doi.org/10.1016/j.jmst.2017.09.005

Zhang JF, Andrae H, Zhang XX et al (2019) An enhanced finite element model considering multi strengthening and damage mechanisms in particle reinforced metal matrix composites. Compos Struct 226:111281

Cao D, Duan Q, Li S et al (2018) Effects of thermal residual stresses and thermal-induced geometrically necessary dislocations on size-dependent strengthening of particle-reinforced MMCs. Compos Struct 200:290–297

Taya M, Lulay KE, Lloyd DJ (1991) Strengthening of a particulate metal matrix composite by quenching. Acta Metall Mater 39:73–87

Zhang XX, Xiao BL, Andrä H, Ma ZY (2014) Homogenization of the average thermo-elastoplastic properties of particle reinforced metal matrix composites: the minimum representative volume element size. Compos Struct 113:459–468. https://doi.org/10.1016/j.compstruct.2014.03.048

Taylor GI (1934) The mechanism of plastic deformation of crystals. Part I. —Theoretical. Proc R Soc London Ser A 145:362–387

Hansen N (1977) The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall 25:863–869

Kwon D (1988) Interfacial decohesion around spheroidal carbide particles. Scr Metall 22:1161–1164. https://doi.org/10.1016/S0036-9748(88)80123-6

Nan C-W, Clarke DR (1996) The influence of particle size and particle fracture on the elastic/plastic deformation of metal matrix composites. Acta Mater 44:3801–3811

Ramazani A, Mukherjee K, Quade H et al (2013) Correlation between 2D and 3D flow curve modelling of DP steels using a microstructure-based RVE approach. Mater Sci Eng A 560:129–139. https://doi.org/10.1016/j.msea.2012.09.046

Zhou J, Gokhale AM, Gurumurthy A, Bhat SP (2015) Realistic microstructural RVE-based simulations of stress-strain behavior of a dual-phase steel having high martensite volume fraction. Mater Sci Eng A 630:107–115. https://doi.org/10.1016/j.msea.2015.02.017

Ma S, Zhang X, Chen T, Wang X (2020) Microstructure-based numerical simulation of the mechanical properties and fracture of a Ti-Al3Ti core-shell structured particulate reinforced A356 composite. Mater Des 191:108685

Srivatsan TS, Al-Hajri M, Smith C, Petraroli M (2003) The tensile response and fracture behavior of 2009 aluminum alloy metal matrix composite. Mater Sci Eng A 346:91–100

Lloyd DJ (1991) Aspects of fracture in particulate reinforced metal matrix composites. Acta Metall Mater 39:59–71

Acknowledgements

SM acknowledge the Graduate School of Purdue University for a Ross Fellowship and a Bilsland Dissertation Fellowship to support his study for PhD with the Purdue Polytechnic Institute

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, S., Zhuang, X. & Wang, X. Particle distribution-dependent micromechanical simulation on mechanical properties and damage behaviors of particle reinforced metal matrix composites. J Mater Sci 56, 6780–6798 (2021). https://doi.org/10.1007/s10853-020-05684-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05684-2